GET KNOWLEDGE OF

SILICON CARBIDE KILN SHELVES

Understanding the Properties of Silicon Carbide Kiln Shelves

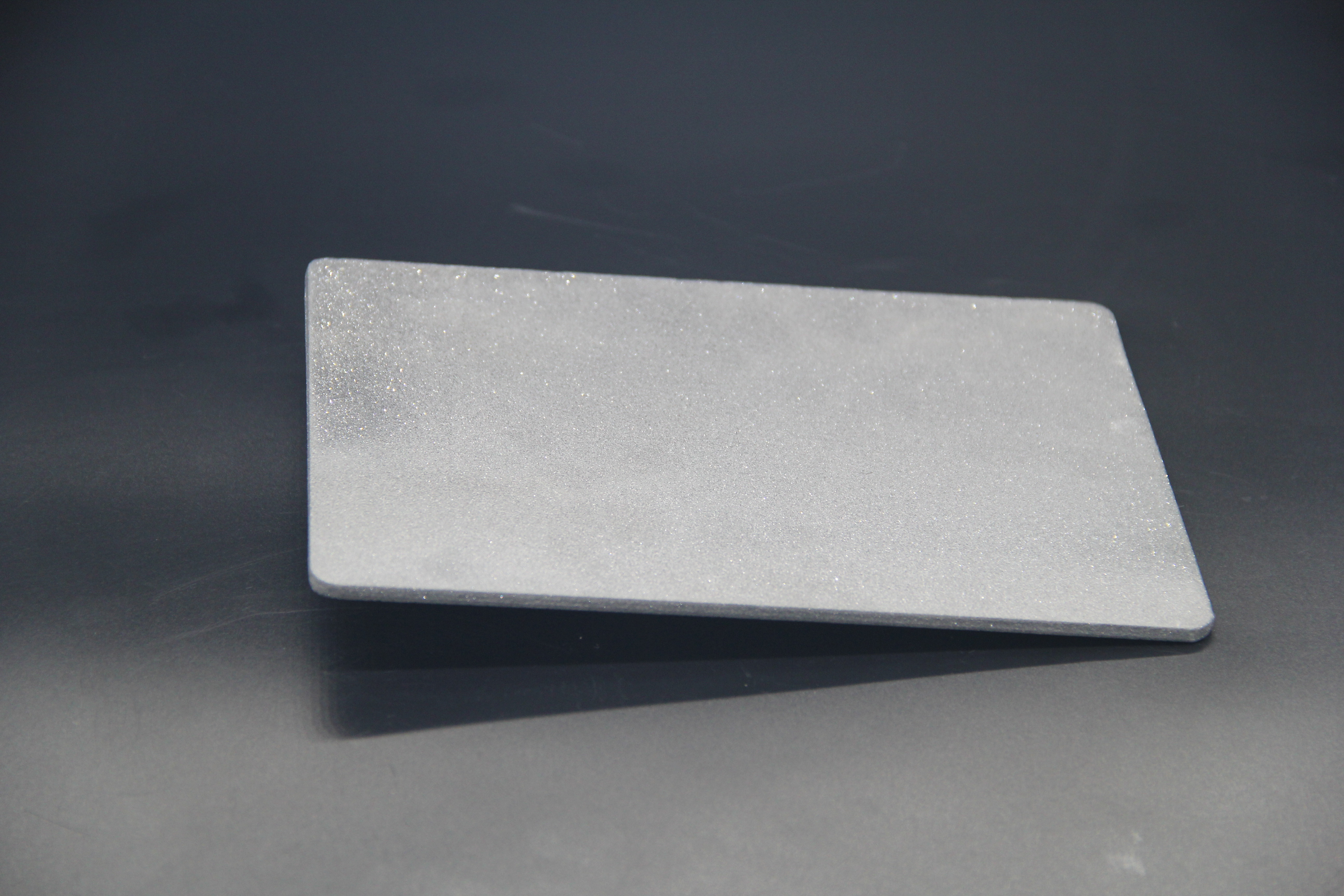

Silicon Carbide Kiln Shelves is specifically engineered to provide exceptional wear resistance and high performance under extreme conditions. This material is renowned for its ability to maintain stability and resist thermal shock at temperatures up to 1,450°C, making it ideal for long-term firing processes. YUFENGREC® Nitride Bonded Silicon Carbide (NbSiC)’s chemical stability and oxidation resistance are superior to Oxide Bonded SiC, ensuring its durability in demanding environments like aluminum melting pots and blast furnaces. With precision shaping capabilities, YUFENGREC® NbSiC is suitable for various industrial applications requiring intricate designs and high resistance to wear.

Showcase of Our Premium Silicon Carbide Kiln Shelves

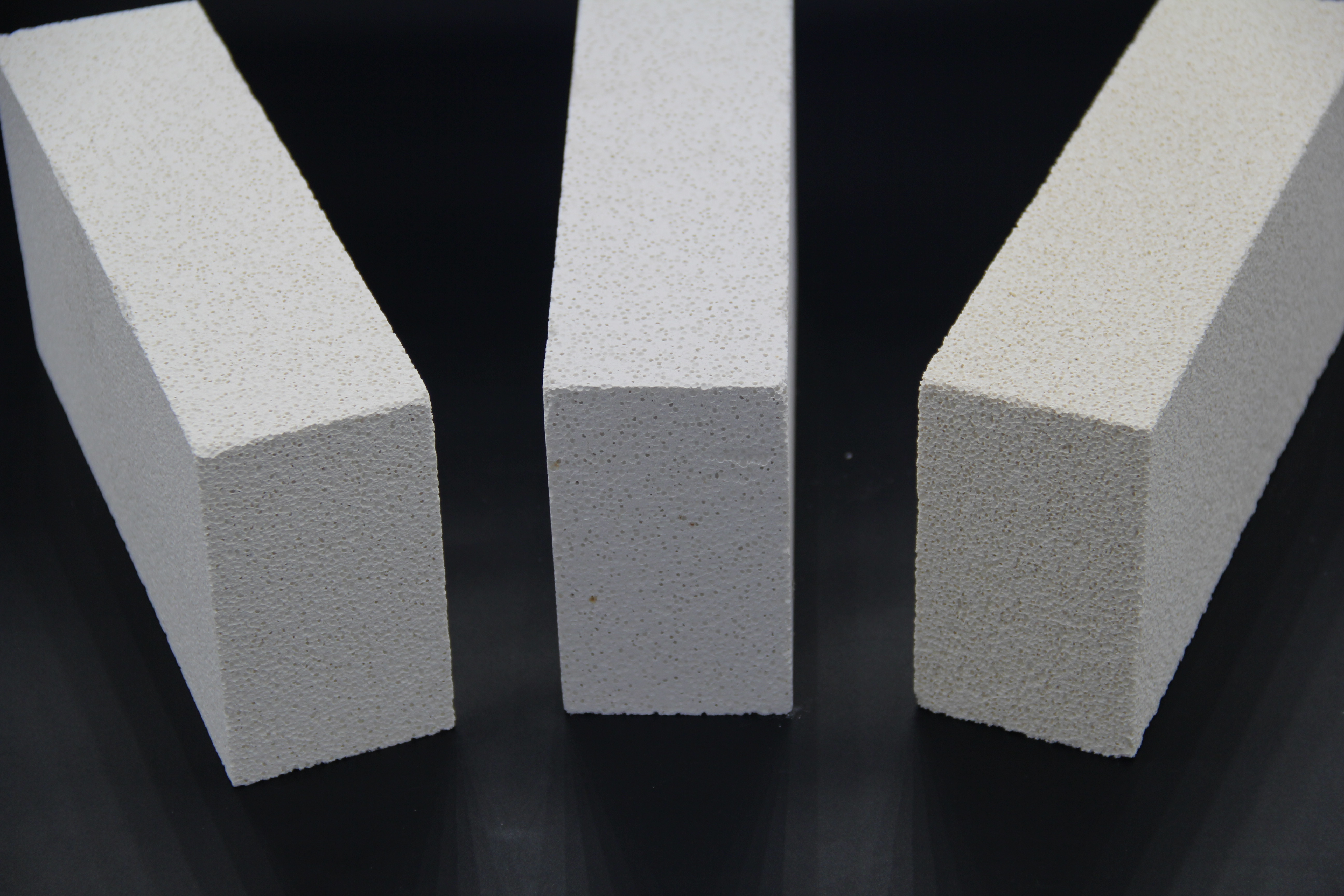

At YUFENG, we offer a wide selection of Silicon Carbide Kiln Shelves, crafted from Nitride Bonded Silicon Carbide (NbSiC). These shelves are ideal for high-temperature firing between 1,200°C and 1,450°C, providing enhanced strength and oxidation resistance compared to traditional materials. Whether you need plates, beams, or custom shapes, our NbSiC kiln furniture can handle the most demanding industrial applications. It’s perfect for use in technical ceramics, metallurgy, and chemical industries, ensuring long-lasting performance and stability.

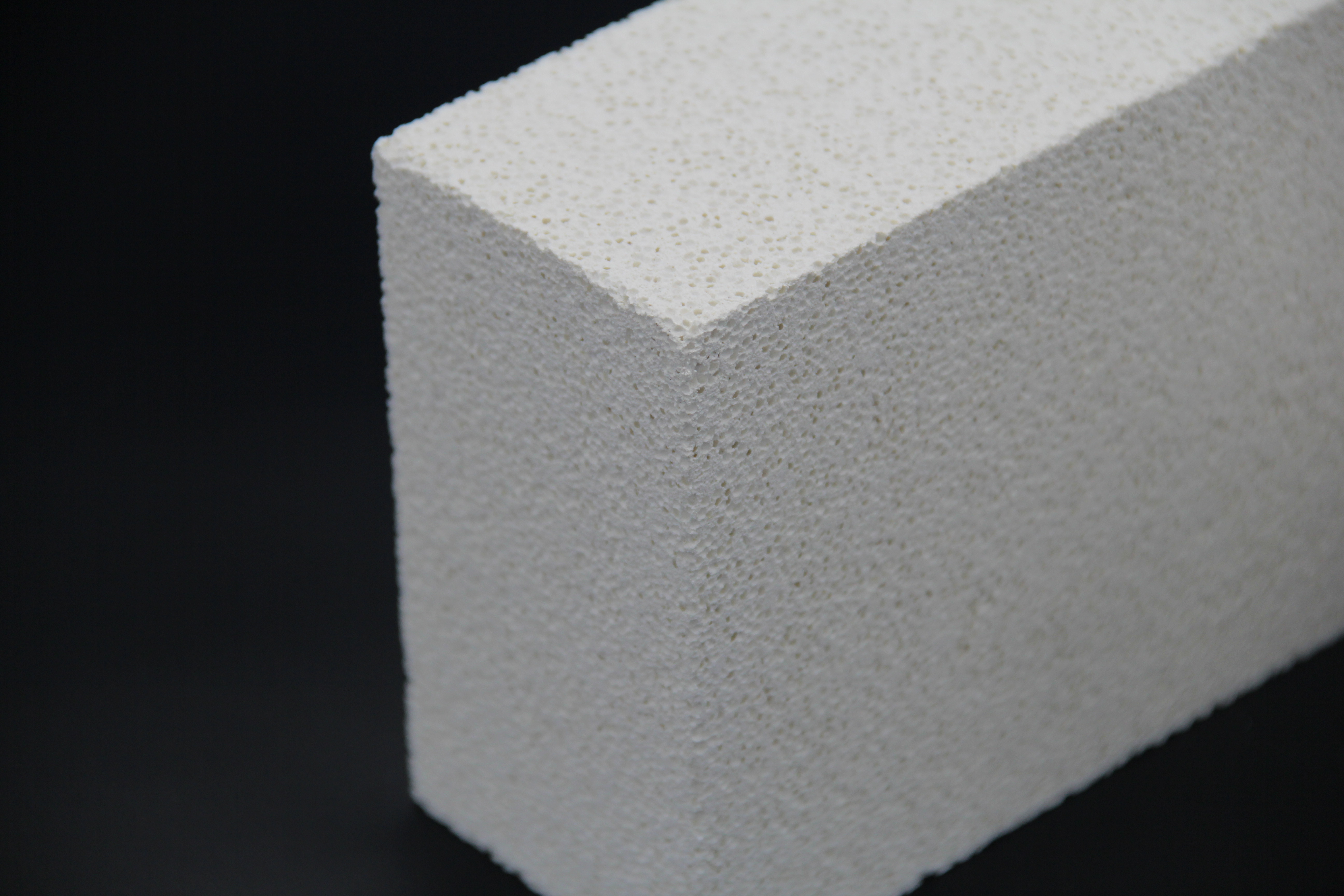

YUFENGREC® provide Super Quality Fireclay Brick with low porosity , are made of pure and high grade Flint Clay(First Grade Hard Clay Clinker ) ,Clay producing by drying pressing and high fired ,with lower porosity ,high crushing strength,good alkali resistance.

YUFENGREC® Nitride Bonded Silicon Carbide (NbSiC) is designed for exceptional wear resistance and can be formed into very intricate and precise shapes with the YUFENG unique process. It has desirable refractory and chemical properties, and can also exhibit exceptional wear and thermal shock resistance.

YUFENGREC® Nitride Bonded Silicon Carbide (NbSiC) is designed for exceptional wear resistance and can be formed into very intricate and precise shapes with the YUFENG unique process. It has desirable refractory and chemical properties, and can also exhibit exceptional wear and thermal shock resistance.

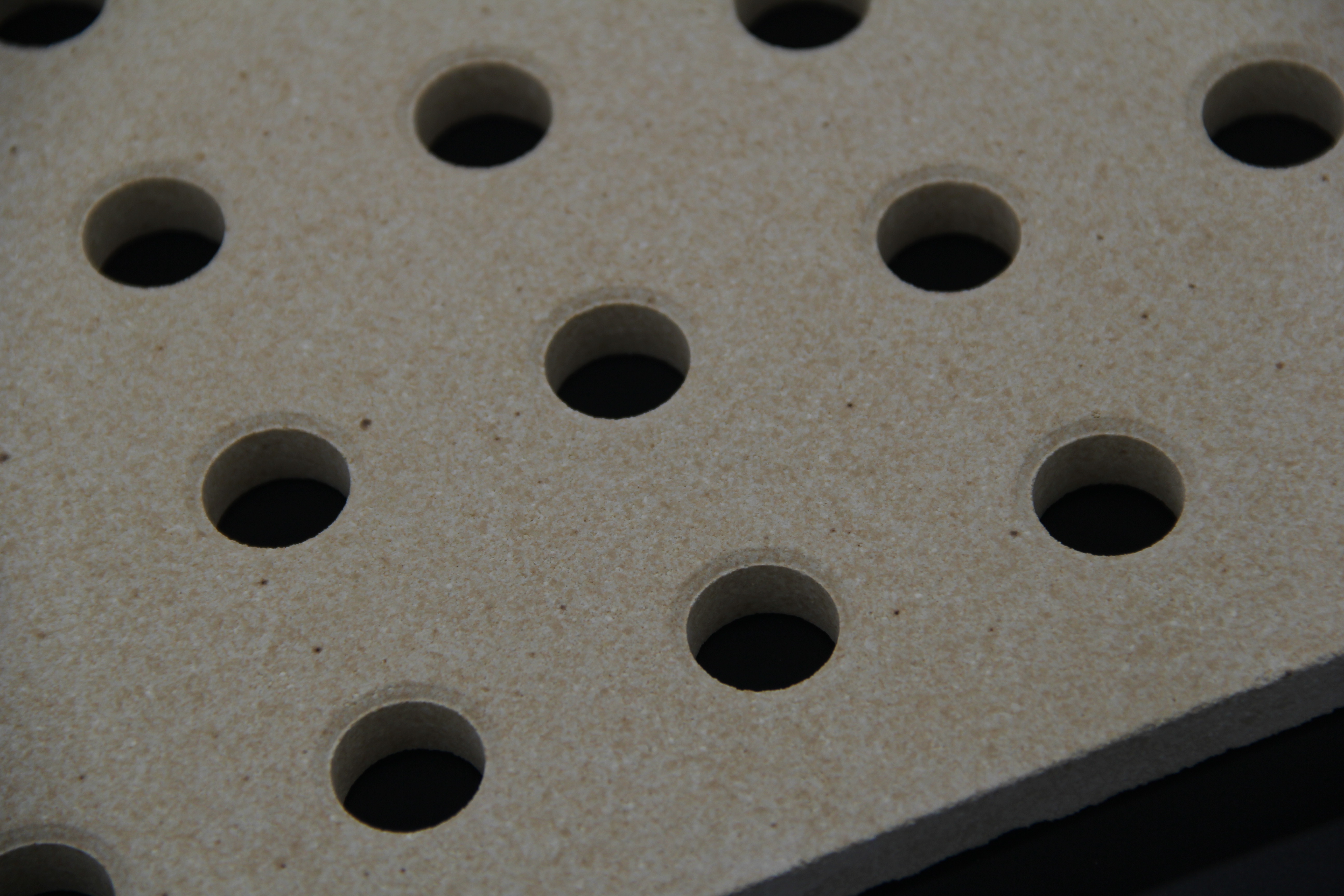

YUFENGREC®Recrystallized Silicon Carbide Kiln Furniture (RSIC), like reaction bonded silicon carbide, can be infiltrated with silicon metal. However, the infiltration process occurs after the primary sintering. This grain structure not only provides excellent material properties, but also enables extremely precise manufacturing along with high purity used in industries like semiconductor production.

it's unique characteristic enables the use of maximum temperature up to 1,600°C, higher than the other SiC refractories.

RSiC, produced by sintering fine SiC grain itself at very high temperature, has very high purity, 99% SiC composition. Suitable to apply firing raw materials or products which need to avoid contaminations. Used as sagger and plate etc.

RSIC batts performances widely in porcelain tableware ,porcelain sanitary ware , metal powder process and electricity produciton etc . due to its ourstanding thermal shock resistance and high thermal conductivity ,RSIC batts can be produced in many shapes ,such as plate , setting ring ,plate setter .etc

This includes steel and alloy ingots for intermediate and large forgings for the transportation, oil, heavy equipment and aeronautical industries. Vacuum remelt electrodes and specialty alloys such as nickel based, nickel cobalt, nickel copper and those alloys which can't be economically continuously cast will continue to be ingot cast.

YUFENGREC®offer a complete range of high quality dry pressed Bottom Pouring Refractory Brick , ranging from 42% to 80% in alumina content. included Sleeve Brick, Runner Bricks ,End Runner brick with riser , Bottom Guide ,Central Brick(Spider) , Funel , Round and Square Tube, Tail brick ,well block , stopper etc ...

Explore Our Extensive Range of High-Quality Silicon Carbide Kiln Shelves

Durable Silicon Carbide Shelves for High-Temperature Industries

Versatile Kiln Shelf Configurations for Industrial Applications

Reliable, Long-Lasting Performance for Extreme Heat Conditions

Customer Success Stories: Yufeng Refractory Silicon Carbide Kiln Shelves

Watch Our Video: High-Performance Silicon Carbide Kiln Shelves in Action

See how YUFENG's Silicon Carbide Kiln Shelves perform under extreme industrial conditions. Our video showcases the durability, stability, and high thermal resistance of our products. Watch how these kiln shelves are used in various applications, including high-temperature furnaces and non-ferrous metal processing equipment. Experience the reliability and quality that YUFENG delivers.

Complete and Customized Support for Your Kiln Shelf Needs

At YUFENG, we pride ourselves on delivering comprehensive and tailored support for all your kiln shelf requirements. With over 30 years of experience in the refractory and advanced ceramics industry, we have developed a reputation for innovation, reliability, and top-tier service. Our deep understanding of alumina-silica-based refractory materials and advanced ceramics allows us to provide solutions that meet the evolving challenges of today’s high-temperature industrial applications.

We are committed to maintaining the highest quality standards across our entire product range, including our Nitride Bonded Silicon Carbide (NbSiC) kiln shelves. Our adherence to ISO9001 for Quality Management, ISO14001 for Environmental Management, and ISO10012 for Measurement System certification ensures that every product we deliver meets strict, consistent quality controls from raw material selection to the final shipment. These certifications reflect our dedication to ensuring long-lasting performance and reliability in all of our products.

Unmatched Quality Assurance

We work closely with trusted raw material suppliers to guarantee the highest quality standards. Extensive quality control is carried out throughout the production process, from sourcing materials to packaging and transportation, ensuring that every kiln shelf meets your specific needs.

Customized Design and Installation Services

Our experienced design and installation teams offer expert solutions to ensure the best performance of your kiln furniture. Whether you need customized shapes or specialized installations, we ensure precision and durability at every step. Our technical team is always ready to provide on-site or remote support, no matter where you are located.

Innovative Solutions

We stay at the forefront of technological advancements in the refractory industry, continuously improving our products to meet the demands of modern industrial applications. Our Nitride Bonded Silicon Carbide shelves are engineered to withstand extreme temperatures, thermal shock, and oxidation, providing long-term value for your operations.

Timely and Secure Delivery

At YUFENG, we understand the importance of timely delivery. We ensure that your orders are processed and shipped on schedule, adhering to the highest safety and quality standards throughout the logistics process. Our commitment to prompt, reliable shipping ensures that your production lines run smoothly and efficiently.

Certified Excellence: Yufeng’s Industry-Approved Silicon Carbide Kiln Shelves

FAQs

Q1: What industries commonly use YUFENG’s kiln shelves?

Our kiln shelves are widely used in industries such as tableware manufacturing, construction tile production, and non-ferrous metal processing. They are also suitable for technical ceramics, sanitary ware, metallurgy, and chemical industries due to their durability and ability to withstand extreme temperatures.

Q2: What temperature range can YUFENG kiln shelves handle?

YUFENGREC® Nitride Bonded Silicon Carbide kiln shelves can withstand prolonged exposure to temperatures ranging from 1,200°C to 1,450°C. They are designed for long-term use in high-temperature environments, making them ideal for kilns and furnaces operating under intense heat conditions.

Q3: How does YUFENG ensure the quality of its products?

We adhere to strict quality control standards throughout our entire production process. YUFENG is certified under ISO9001 for Quality Management, ISO14001 for Environmental Management, and ISO10012 for Measurement System. These certifications ensure that our kiln shelves consistently meet the highest performance standards.

Q4: Can YUFENG provide customized design and installation services?

Yes, we offer complete design and installation services tailored to your specific kiln or furnace needs. Our experienced teams work closely with clients to ensure that our products are installed correctly, ensuring maximum performance and longevity. We provide support both on-site and remotely.

Q5: What are the key benefits of choosing YUFENG kiln shelves?

Our kiln shelves provide superior thermal shock resistance, oxidation resistance, and mechanical strength. They are designed for high-temperature applications, reducing downtime and maintenance costs, while improving the overall efficiency and longevity of your production processes.