Refractory Bricks – High-Performance Solutions for Extreme Temperatures

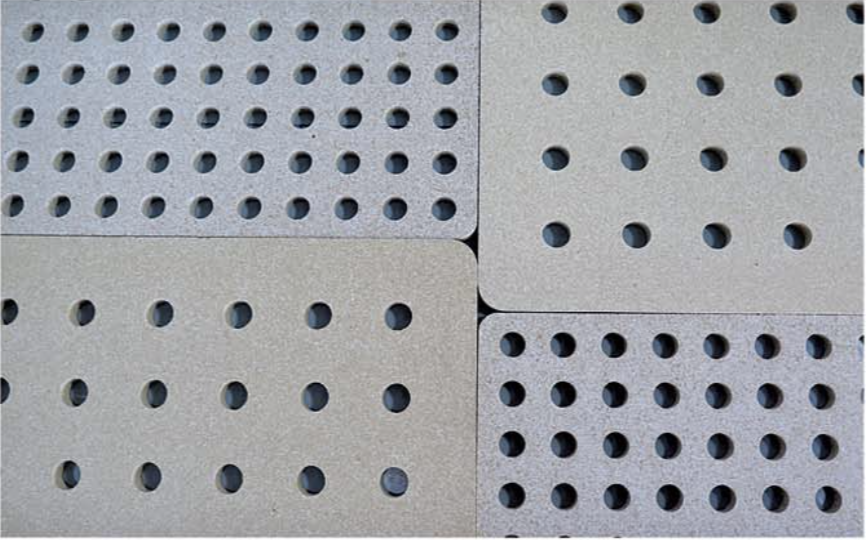

Introduction to Refractory Bricks

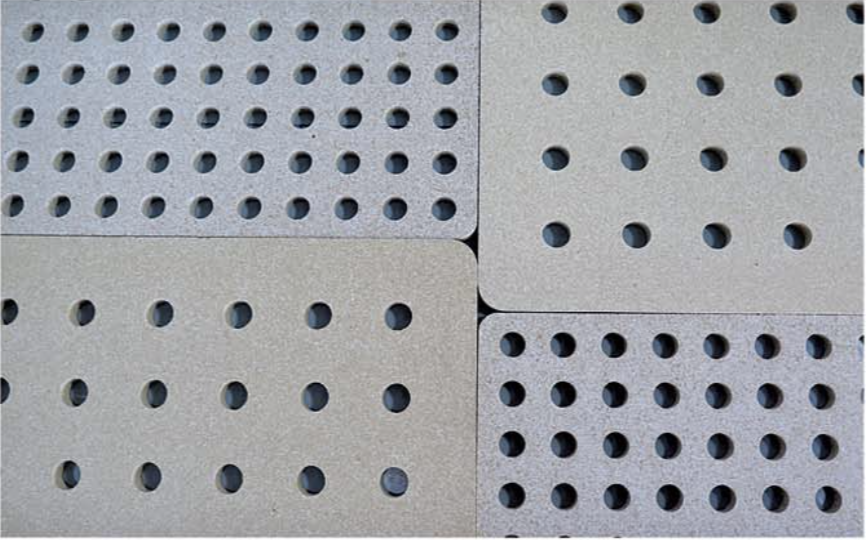

Refractory bricks are heat-resistant materials essential in various high-temperature applications, including furnaces, kilns, and reactors. These bricks are designed to withstand extreme heat, maintain their shape and strength under pressure, and provide excellent thermal insulation, making them crucial for industries like steel manufacturing, cement production, and glass production.

Alumina-Silica Refractory Bricks

Magnesia-Based Refractory Bricks

Mullite Refractory Bricks

Refractory Brick Applications

Steel and Metal Production

Furnaces

Ladles

Casting Applications

Steelmaking and Alloy Production

Iron Smelting

Cement Manufacturing

Rotary Kilns

Preheating Towers

Calcining Systems

Cement Clinker Production

Heat Retention Systems

Power Plants

Boilers

Furnaces

Turbine Housings

Heat Exchangers

Coal-Fired Power Plants

Industrial Kilns

Ceramic Kilns

Brick Kilns

Refractory Drying Ovens

Cement Rotary Kilns

Pottery and Ceramic Kilns

Furnace and Heat Treatment Applications

Heat Treatment Furnaces

Forging Furnaces

Annealing Furnaces

Heat Tunnels

High-Accuracy Laboratory Instruments

Refractory Brick Manufacturing Process

Step 1: Molding

The first step involves mixing raw materials, such as bauxite and silica, in precise proportions. These materials are then shaped into brick forms using high-precision molds. Various molding techniques, including pressing and injection, are employed to ensure uniformity and consistency across all bricks.

Step 2: Drying

After molding, the bricks are carefully dried to remove any moisture content. This step is essential to prevent cracking and ensure the structural integrity of the bricks. The drying process is controlled carefully in specialized chambers, with temperature and humidity monitored to ensure the bricks maintain their shape and quality.

Step 3: Sintering

In this critical step, the dried bricks are subjected to high temperatures in a sintering furnace. This process fuses the raw materials into a dense and durable structure. The precise control of temperature and time during sintering is essential for enhancing the brick’s thermal stability, strength, and durability.

Step 4: Quality Control

To ensure every brick meets the highest standards, a thorough quality control process is carried out. Each batch is subjected to rigorous testing, including advanced techniques such as X-ray and ultrasound inspections. These tests check for defects, ensuring that only defect-free products are delivered to customers.

Why Choose OurRefractory Bricks?

Innovative Manufacturing Process

Industry Certifications & Global Recognition

Customized Solutions for Various Industries

Exceptional Durability & Performance

Expert Support & After-Sales Service

About us

ZIBO YUFENG REFRACTORY CO., LIMITED

Founded in 1989, we have over 30 years of experience as a leading manufacturer of alumina-silica-based refractory products and advanced ceramics. Our expertise and dedication have enabled us to develop and supply high-quality refractory materials, including Refractory Bricks, that meet the stringent requirements of industries worldwide.

We continuously focus on meeting future challenges by ensuring that our materials are of the highest quality. Our commitment to innovation, excellence, and customer satisfaction is reflected in our robust ISO9001 Quality Management System, ISO14001 Environmental Management System, and ISO10012 Measurement System certifications, which guarantee quality control across all stages of production.

With a state-of-the-art manufacturing facility and a dedicated team of experts, we serve key industries such as iron & steel, cement, glass, aluminum, ceramics, and foundry. Our refractories, including Refractory Bricks, are known for their exceptional thermal stability, mechanical strength, and long-lasting performance, ensuring reliable solutions for high-temperature applications.

Frequently Asked Questions

Q1: What materials are used in the production of refractory bricks?

Our refractory bricks are primarily made from bauxite, silica, and refractory fibers, which provide the necessary thermal and mechanical properties.

Q2: Can refractory bricks be customized for specific applications?

Yes, we offer custom solutions based on your specific temperature and durability requirements.

Q3: What is the maximum temperature a refractory brick can withstand?

Our refractory bricks are designed to handle temperatures up to 1800°C, making them suitable for the most demanding environments.

Q4: How long do refractory bricks last?

The lifespan of refractory bricks depends on various factors, including the temperature, exposure to chemical or mechanical stresses, and maintenance. In typical industrial applications, refractory bricks can last several years with proper care and regular maintenance.

Q5: Are your refractory bricks resistant to thermal shock?

Yes, our refractory bricks are designed to resist thermal shock, ensuring they can withstand rapid temperature changes without cracking or degrading. This makes them ideal for use in high-temperature environments where temperature fluctuations are common.

Related Blogs

-

Cordierite - Mullite is a combination of Cordierite Phase ,Mullite Phase and Glass Phase , with excellent thermal shock resistance and high temperature resistance . Cordierite - Mullite Kiln Furniture is the most suitable refractory under 1300 , it is widely used in Tableware ,Sanitary WaProduct News

Cordierite - Mullite is a combination of Cordierite Phase ,Mullite Phase and Glass Phase , with excellent thermal shock resistance and high temperature resistance . Cordierite - Mullite Kiln Furniture is the most suitable refractory under 1300 , it is widely used in Tableware ,Sanitary WaProduct News -

With the continuous development of some industries in China, people put forward higher requirements for refractory bricks. Therefore, the refractory industry, which has long relied on a wide range of economic growth modes, should intensify its adjustment to meet the needs of the new situation. In the next few years, the prospect of refractory brick industry will continue to expand. At present, brick has a wider range of applications. Only by first understanding it can we better tap its value. So, what is dense brick? How did it perform? In the following article, we briefly introduce this, hoping to help you better understand the dense brick.Product News

With the continuous development of some industries in China, people put forward higher requirements for refractory bricks. Therefore, the refractory industry, which has long relied on a wide range of economic growth modes, should intensify its adjustment to meet the needs of the new situation. In the next few years, the prospect of refractory brick industry will continue to expand. At present, brick has a wider range of applications. Only by first understanding it can we better tap its value. So, what is dense brick? How did it perform? In the following article, we briefly introduce this, hoping to help you better understand the dense brick.Product News -

Yufeng SonotekSic® Sintered Silicon Carbide (SSiC) is pressure-less, sintered form of alpha silicon carbide, with very fine grain structure (4-10 microns) and contains no free silicon. it is made of pure sub-micron SiC powder with non-oxide sintering aids. forming by extrusion, dry pressing .Product News

Yufeng SonotekSic® Sintered Silicon Carbide (SSiC) is pressure-less, sintered form of alpha silicon carbide, with very fine grain structure (4-10 microns) and contains no free silicon. it is made of pure sub-micron SiC powder with non-oxide sintering aids. forming by extrusion, dry pressing .Product News

Get in Touch with Us

If you're ready to place an order or need more information about our Refractory Bricks, don’t hesitate to get in touch with our dedicated customer service team. Our experts are here to guide you through the entire process—whether it's helping you select the right brick specifications or providing a tailored quote for your project. We are committed to delivering high-performance solutions that meet your unique needs, ensuring smooth delivery and installation every step of the way.

Mob

+86-138-6938-1053