YUFENG leads the ceramic and refractory in design ,development and production of kiln furniture solutions for extreme working conditions and high temperature applications , specializing in researching and supplying Cordierite Mullite Kiln Furniture , Silicon Carbide Kiln Furniture, Alumina Kiln Furniture.

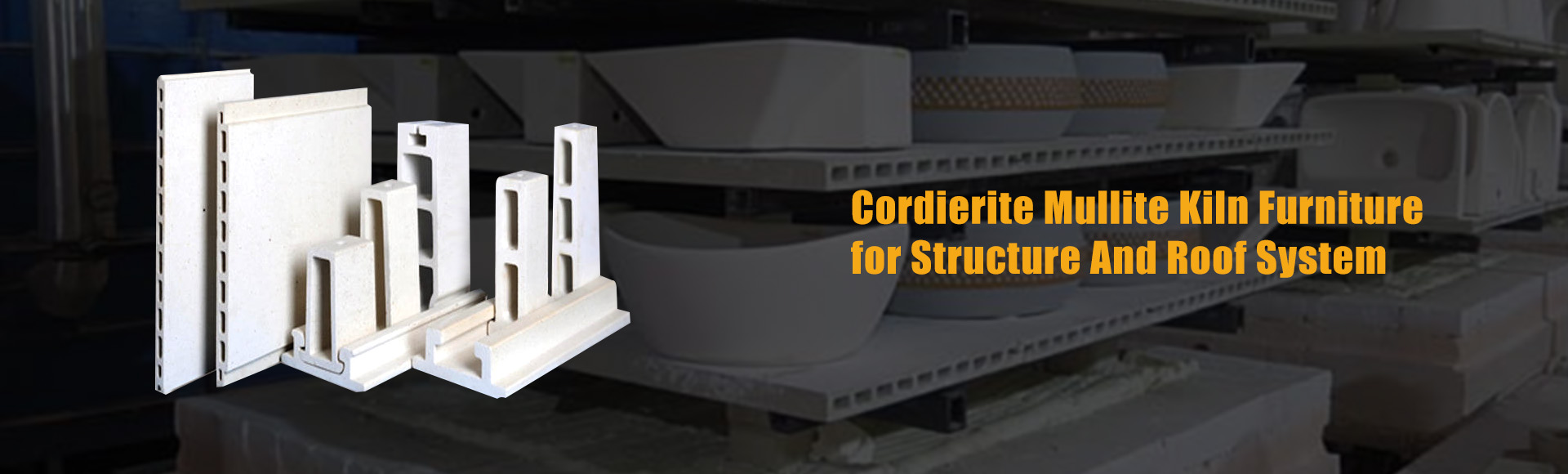

Cordierite-Mullite is a combination of Cordierite Phase ,Mullite Phase and Glass Phase , feature with excellent thermal shock resistance ,high temperature resistance ,which is the most suitable material making kiln furniture especially service under 1300 Deg C .

Cordierite-Mullite Kiln Furniture are widely used in the Table Ware , Sanitary ware , Electrical Porcelain Insulator , Powder Calcination , Technical Ceramic industry .

Silicon Carbide retains most of its mechanical strength under high temperature and exhibits very low creep , making it first choice for load-bearing applications in the range 1300 Deg C to 1650 Deg C . (Oxide Bonded SiC , Nitride Bonded SiC , Recrystallized SiC and Sintered SiC can be choose according to different applications )

Silicon Carbide Batts / Shelves

Silicon Carbide Beams

Silicon Carbide Nozzles

Silicon Carbide Tubes & Rollers

Silicon Carbide Saggars

Silicone Carbide Setters

Silicon Carbide Batts / Shelves

Are extensively as supports in kiln and furnace constructions ,used for the loading structure systems of the tunnel kiln, shuttle kiln and many other industrial kiln or furnaces . SiSiC cross beams with high strength ,no deformations even under high temperature, which is the most suitable kiln furniture for sanitary ware ,electrical porcelain applications .

The Sanitary Ceramic Kiln Furniture has a large carrying capacity and a high loading height, so the high temperature strength of the kiln furniture and the stability of the system operation are very demanding.

Kiln Furniture is a key component of the Sanitary Ware production process , it directly affect the below mentioned :

There are many kinds of tableware ceramics, with different firing process is different, and the shape of the product is also ever-changing, so the kiln furniture system used is also the most complicated. Choosing a suitable kiln furniture system can increase the rate of high-quality products, increase the loading capacity of the kiln, reduce fuel consumption, and reduce labor intensity, thereby greatly saving costs. We have developed kiln furniture systems currently used by all types of porcelain at home and abroad, which can provide a full range of kiln furniture solutions for the daily ceramic

Key Feature

Ceramic kiln furniture has no pollution to the sintering of ceramic products. The corrugated structure is specially designed for ceramic product sintering. The smallest contact area enables the product to achieve small interference during the entire high-temperature sintering process. At the same time, it has very good finish and high-precision V-shaped grooves. Ensure the sintered finish and shape and dimensional accuracy of ceramic products. The design of the V-shaped groove ensures the consistency of the size of the ceramic product with a 100% pass rate. Our company has various specifications of V-groove plates, and we can also design and customize different V-groove plates according to the size of customers' products.

In the secondary battery (energy for IT industry technology) market, with the expansion of mobile and applicable products, the necessity for the development of products related to the low-carbon environment is becoming stronger. In the secondary battery market, the market for lithium batteries (high-performance, low-carbon environmental materials) is gradually increasing.

The important material of the secondary lithium battery is the cathode material. We specialize in producing high-quality corrosion-resistant bowls for calcining cathode materials.

High-alumina sintered backing plate (corundum mullite bearing plate) used in continuous furnace vacuum furnace sintering MIM stainless steel parts shows excellent sintering performance. The effective porosity enables the sintering backing plate to ensure very low energy storage, and the high-purity inert chemical composition ensures that the sintering process of MIM stainless steel parts will not occur chemical reactions such as carburization, decarburization, and dichotomization.

In order to achieve this , We carefully build up business with our raw material suppliers, establish the specification ands advance the quality level with our reliable suppliers , Control the quality from the very beginning . We perform extensive quality control during the entire production process, packing, and transportations.

Cordierite-Mullite is a combination of Cordierite Phase ,Mullite Phase and Glass Phase , feature with excellent thermal shock resistance ,high temperature resistance ,which is the most suitable material making kiln furniture especially service under 1300 Deg C .

Cordierite-Mullite Kiln Furniture are widely used in the Table Ware , Sanitary ware , Electrical Porcelain Insulator , Powder Calcination , Technical Ceramic industry .

Silicon Carbide retains most of its mechanical strength under high temperature and exhibits very low creep , making it first choice for load-bearing applications in the range 1300 Deg C to 1650 Deg C . (Oxide Bonded SiC , Nitride Bonded SiC , Recrystallized SiC and Sintered SiC can be choose according to different applications )

| Name | Introduction | Size | Downloads | Update | Category | Thumbnail | Copy Link | Download |

|---|---|---|---|---|---|---|---|---|

| Soluble Fiber Blanket MSDS .pdf | 196KB | 238 | 2019-06-04 | SDS |  | Copy Link | ||

| Fiber Blanket HP 2300 MSDS .pdf | 215KB | 232 | 2019-06-04 | SDS |  | Copy Link | ||

| Fiber Blanket HZ 2600 MSDS.pdf | 209KB | 213 | 2019-06-04 | SDS |  | Copy Link | ||