Views: 0 Author: Site Editor Publish Time: 2025-08-25 Origin: Site

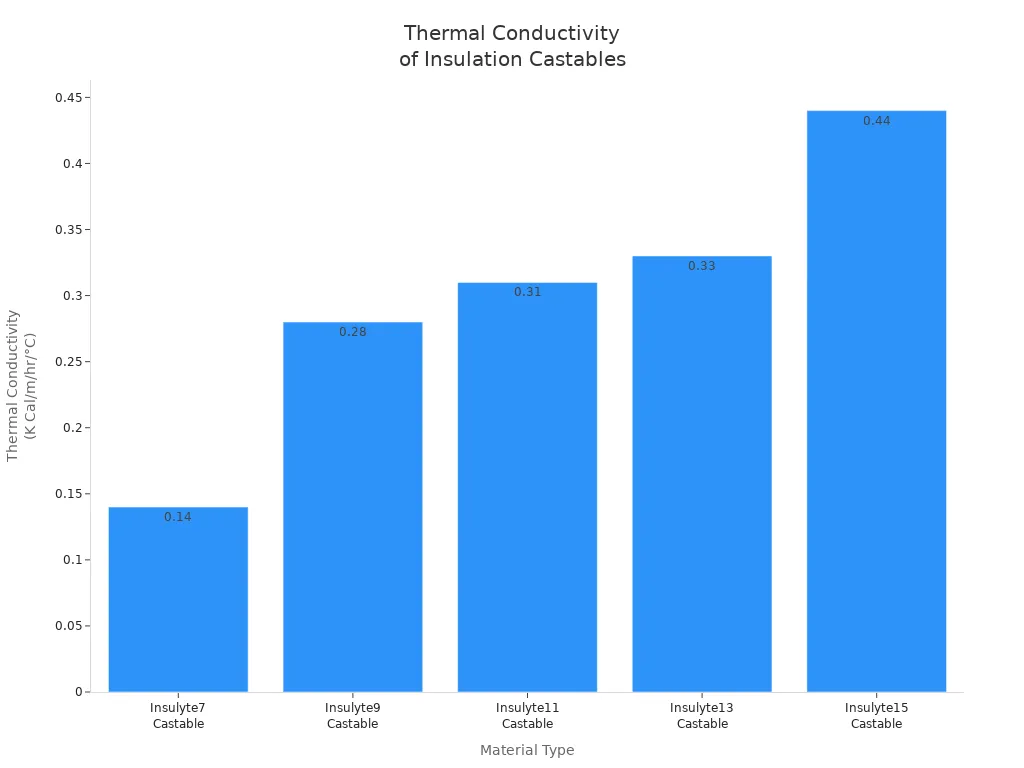

An excellent thermal insulator stops heat from moving through it easily. Materials with low thermal conductivity, like monolithic refractories, slow heat transfer. They do this by trapping air or using thick structures. The table below shows that monolithic refractories, such as Insulyte castables, have thermal conductivity values from 0.14 to 0.44 K Cal/m/hr/°C at 500 °C.

Low thermal storage helps keep temperatures steady. But low thermal conductivity is still the most important thing. Monolithic refractories give good insulation in places with high heat.

Monolithic refractories do not let heat pass easily. They have small pores that hold heat inside. This makes them great insulators in very hot places.

These materials can handle chemicals and high heat. They also resist wearing down and quick temperature changes. This helps them last longer and save energy.

There are different types of monolithic refractories. Some are castables, plastic mixes, ramming, and gunning materials. Each type works best for certain ways of putting them in and for different jobs.

Their linings do not have joints, so less heat escapes. This also means there are fewer weak spots. This makes machines safer and work better in factories.

Monolithic refractories are easy to put in and fix. This saves money and makes them a top choice in steel, cement, and glass factories.

Monolithic refractories are a type of material used in hot places. They do not need to be shaped into bricks before use. Factories send them as powders, pastes, or slurries. Workers put them in place by casting, spraying, ramming, or gunning. This lets the material fit the equipment’s shape. It makes a smooth lining with no gaps. Shaped refractories come as bricks or blocks with set sizes. Monolithic refractories can fit many shapes. Their tiny pores, about 1-2 μm, help them handle sudden heat changes. These pores also lower thermal conductivity by up to 30%. The structure helps stop corrosion and lets the lining stretch without cracking. The table below shows how monolithic refractories and shaped refractories are different:

| Feature | Monolithic Refractories | Shaped Refractories |

|---|---|---|

| Structure | Unshaped, installed on-site | Preformed bricks/blocks |

| Geometric Flexibility | High | Limited |

| Installation Method | Casting, spraying, ramming, gunning | Manual installation |

| Mechanical Strength | Moderate | High |

| Thermal Resistance | Medium to High | High |

| Thermal Shock Resistance | Adjustable via mix design | Depends on brick type |

| Repair & Maintenance | Local patching possible | Entire section replacement required |

| Thermal Efficiency | Fewer joints, reducing thermal loss | More seams, increasing heat leakage |

| Cost | More economical | Higher cost |

Monolithic refractories have fewer joints. This means less heat escapes and energy is saved. Their way of installing also makes fixing them easier and cheaper.

Refractory materials are important in places with high heat. They can handle very hot temperatures, strong force, and chemicals. Factories that make steel, cement, and glass use them to protect machines and keep things running smoothly. There are different types, like monolithic refractories, shaped bricks, castables, plastic mixes, and gunning materials. Each type works best for certain jobs, like lining furnaces or insulating kilns. Monolithic refractories are popular because they are easy to install and keep heat in well. Their tiny pores help them handle sudden heat changes and lower thermal conductivity. This makes them good for saving energy.

The market for monolithic refractories is getting bigger. In 2023, it was worth USD 6.5 billion. By 2032, it may reach USD 10 billion. This is because more iron and steel factories need them, especially in Asia-Pacific. Monolithic refractories help save energy and follow new rules for the environment. The whole refractory market, with all types and uses, was worth USD 34 billion in 2024. It could grow to USD 46 billion by 2033. Monolithic refractories are getting more popular because they are easy to use and work well.

Refractory materials keep changing to meet new needs. Makers create new kinds for modern factories. Monolithic refractories are special because they can fit many shapes, last long, and cost less. They are very important for keeping heat in and making sure machines work safely in hot places.

Monolithic refractories work well in tough factories. They have chemical inertness, high-temperature resistance, and strong abrasion and thermal shock resistance. These features make them great for insulation and protection where it gets very hot. Knowing about these properties shows why monolithic refractories are good at stopping heat from moving and storing.

Chemical inertness is a key property of monolithic refractories. This means the material does not react with other things, even with strong chemicals or high heat. Makers use stable oxides like alumina, silica, magnesia, and lime. Sometimes, zirconia is added for more strength and resistance.

These oxides are important because they stay stable and do not react at high heat. So, monolithic refractories can handle harsh places like steel, glass, and cement factories. Their chemical inertness stops reactions that could hurt the lining or mess up the product.

Note: Chemical inertness helps monolithic refractories keep their shape and work well, even with strong chemicals or melted metals.

This property helps keep thermal conductivity and thermal storage low. If a refractory does not react with its surroundings, it keeps its insulating shape. This helps keep insulation steady, so less heat is lost and less energy is used.

High-temperature resistance shows how well a refractory can take extreme heat without melting or breaking. Monolithic refractories are very good at this. Many can handle over 1500°C, which is much higher than most insulation materials. For example, high alumina-silica bricks in aluminum furnaces can go up to about 1700°C. Fireclay refractories can last up to 1587°C, depending on what they are made of.

This strong resistance comes from picking and mixing the right materials. Alumina and silica give both strength and stability at high heat. These materials do not get soft or lose shape, even with direct flame or melted metal.

Labs use different tests to check high-temperature resistance:

X-ray fluorescence (XRF) checks what the material is made of.

X-ray diffraction (XRD) looks at the structure and changes at high heat.

Scanning electron microscopy (SEM) checks the tiny structure for damage.

Special tests also copy real furnace conditions. For example, aluminum 'cup' tests put samples in melted aluminum at up to 1,832°F (1,000°C) for a long time. After testing, experts look for metal getting in, surface damage, and changes in the material.

These tests show that monolithic refractories keep their strength and insulation, even in very tough conditions. Their high-temperature resistance keeps heat where it should be, saves energy, and protects equipment.

Factories often have high heat, moving parts, and quick temperature changes. Monolithic refractories must resist both abrasion and thermal shock to work well.

Abrasion resistance means the material can take wear from moving solids like ash, slag, or metal. High-alumina castables, a type of monolithic refractory, are much better at this than regular bricks. Studies show these castables can improve wear resistance by 60% to 90%. This is because of higher density, special micro powder, and hard pieces like silicon carbide. Silicon carbide is very hard and does not wear down easily.

Tip: Picking monolithic refractories with better abrasion resistance can make furnace linings last longer and lower repair costs.

Thermal shock resistance means the material can handle fast temperature changes without cracking. In lab tests, alumina-based monolithic refractories survived up to 30 cycles of quick heating and cooling with about 900°C swings. The elastic modulus, which shows stiffness, drops by about 70% after many shocks, but then stops dropping. This happens because small cracks form and fill up, so big cracks do not spread.

The mix and structure of monolithic refractories help with thermal shock resistance. Materials like andalusite, spinel, and zirconia-alumina make extra phases that soak up energy and stop cracks. These features let monolithic refractories take sudden temperature changes, which happen a lot in factories.

Having both abrasion and thermal shock resistance means monolithic refractories keep their insulation over time. They do not break down or stop working, even in rough, changing places. This helps keep thermal conductivity and thermal storage low, making them great for lining furnaces, kilns, and reactors.

Key characteristics of monolithic refractories:

| Property | Benefit in Industrial Use |

|---|---|

| Chemical inertness | Stops reactions, keeps structure strong |

| High-temperature resistance | Handles high heat, protects machines |

| Abrasion resistance | Less wear, longer lining life |

| Thermal shock resistance | Takes fast temperature changes, stops cracks |

These properties make monolithic refractories some of the best and most dependable refractory materials for high-temperature insulation. They can resist chemical attack, high heat, and both mechanical and thermal stress. This means they last a long time and help save energy in factories.

Monolithic refractories come in different types for special jobs. These include castables, plastic mixes, ramming, and gunning materials. Each type uses its own mix of aggregates and bonding agents. The type you pick depends on how you install it, where it goes, and what you need it to do.

Castables are very useful refractory materials. Companies send them as dry mixes with aggregates, binders, and additives. Workers add water and pour the mix into molds or onto surfaces. They use vibration to pack the mix tightly. This makes a strong and dense lining. Castables need to cure for one to three days, then dry slowly. This gives them high strength and good abrasion resistance.

Castables use different aggregates like alumina, silica, or magnesia. Dense castables are good for furnace linings and places with heavy wear. Insulating castables have light aggregates to keep heat in and lower heat loss. Low cement castables last longer in tough spots.

Castables make linings without joints, so less heat escapes. They can fit odd shapes and fix damaged spots fast.

Plastic mixes are soft, clay-like refractory materials. Workers can shape them by hand or with simple tools. This makes them great for fixing and patching linings. These mixes have aggregates, plasticizers, and binders for easy molding.

Plastic mixes work well where temperatures change a lot. Their structure lets them stretch and shrink without cracking. Some plastic blends, like those with LDPE, stay stable when heated again and again. The aggregates give them strength and help stop wear.

Factories use plastic mixes for furnace linings, pipes, and tricky shapes. They fit uneven surfaces, so they are easy to install. Plastic mixes also handle quick temperature changes, so linings stay strong.

Ramming and gunning materials help make linings without joints. Ramming mixes are dry and have aggregates and binders. Workers pack them in tight to make a tough, thick lining. This works well for cold walls and places that need careful shaping.

Gunning materials are sprayed onto surfaces with special tools. This covers big or hard-to-reach spots fast. Gunning mixes stick well to old linings, so they are good for repairs.

Both ramming and gunning materials use special aggregates for the right properties. Ramming mixes can make layers that are tough and stable. Gunning mixes go on fast and help fix things quickly.

| Type | Main Aggregates Used | Application Method | Key Benefits |

|---|---|---|---|

| Castables | Alumina, silica, magnesia | Pouring, vibration | High strength, abrasion resistance, jointless lining |

| Plastic Mixes | Fireclay, high alumina | Hand shaping, patching | Thermal shock resistance, easy repair |

| Ramming Materials | Graded aggregates | Ramming, compacting | Dense, durable, jointless lining |

| Gunning Materials | Similar to castables | Spraying | Fast repair, covers irregular surfaces |

Ramming and gunning materials make linings that are smooth and have no joints. This helps equipment last longer and stay safe in hot places.

These types of monolithic refractories are important for hot industrial jobs. Their special mixes and ways of installing them make linings that save energy and last a long time.

Monolithic refractories are easy to install in many ways. Workers can use shotcrete, gunite, ramming, or casting. Each way changes how much the job costs and how fast it goes. The table below shows how these ways are different:

| Installation Method | Description | Impact on Project Costs |

|---|---|---|

| Shotcrete | Low-cement, low-moisture refractory sprayed at high velocity onto surfaces. | High volume application reduces installation time but requires skilled crew to minimize waste and control costs. |

| Gunite | Dry refractory sprayed with compressed air, mixed with water at nozzle, compacted on placement. | Similar to shotcrete, allows fast installation; skilled labor needed to avoid material waste and cost overruns. |

| Ramming | Hand-rammed refractory using pneumatic hammer, with or without forms. | More manual and slower; may be suitable for specific site conditions; potentially higher labor costs but less waste if done properly. |

| Casting | Pouring wet castables into forms, which are removed after setting. | Slower process; labor intensive; cost depends on formwork and curing time; suitable for complex shapes. |

The best way depends on the job site, how much material is needed, and how skilled the workers are. Fast setup and simple repairs help factories save time. This is important in places like steel plants, where every hour matters.

Jointless linings are a big benefit of monolithic refractories. These linings are thick and even, so they do not crack when temperatures change quickly. The good things about jointless linings are:

They handle fast temperature changes, so they last longer.

Fewer joints mean fewer weak spots, so steel and slag cannot get in easily.

They stay strong, work well, and resist wear and damage from chemicals.

Jointless linings keep heat inside machines, so they are great thermal insulators in hot places.

Monolithic refractories keep working well, even after many heating and cooling cycles. Their thick structure and special ingredients stop damage from chemicals. New ideas, like low cement castables and nanotechnology, make them even stronger. Some types can fix small cracks by themselves, so they last longer. In real factories, monolithic rings in furnaces last more than twice as long as old types. Precast monolithic crucibles in aluminum factories also last longer and do not break from heating and cooling.

These benefits—easy setup, jointless linings, and long life—make monolithic refractories a top pick for factories that need strong insulation and protection in hot places.

Monolithic refractories are great thermal insulators because they have low thermal conductivity, last a long time, and can make linings without joints. Their special pores and strong crystal structure help save energy in tough factory conditions. When engineers pick insulation, they look at things like R-value, how well it handles water, and how strong it is:

| Key Factor | Why It Matters |

|---|---|

| Low Thermal Conductivity | Reduces heat loss, saves energy |

| Durability | Ensures long service life |

| Moisture Tolerance | Prevents damage and failure |

Monolithic refractories give strong and steady insulation for places that need it most.

Monolithic refractories can handle very high heat. They do not react with chemicals. They are tough against wearing down. These materials make linings with no joints. Jointless linings help keep heat inside. This is important in hot factories. Their features make them good for steelmaking and other hard jobs.

There are different kinds of monolithic refractories. These include castables, plastic mixes, ramming, and gunning materials. Each kind uses special ingredients and ways to install. Castables work well for tricky shapes. Gunning materials help fix things quickly. The type you pick depends on the job and where it goes.

Industries like monolithic refractory linings for many reasons. These linings have fewer joints. They are easy to put in and fix. They last a long time and save energy. Their low thermal conductivity helps machines work better in hot places.

Refractory materials can take very high heat. They do not get damaged by chemicals. These features protect machines in steel, cement, and glass factories. The materials stay strong and work well even when it gets very hot.

Aggregates change how dense and strong the refractory is. They also affect how well it keeps heat. Picking the right aggregates helps stop wear and hold in heat. Good choices make sure the refractory works well in hot factories.