Views: 0 Author: Site Editor Publish Time: 2025-08-24 Origin: Site

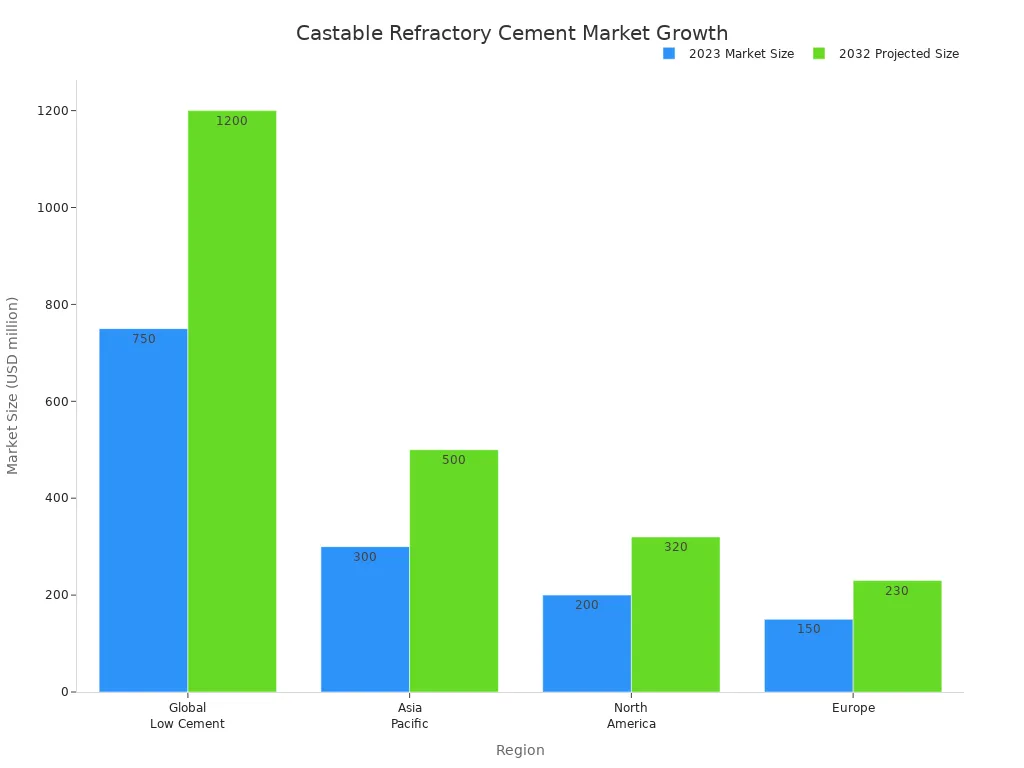

Castable refractory cement is a special material for heat-resistant buildings. It is a kind of monolithic refractory. It mixes powders and binders. When you add water, it makes strong linings. These linings protect against high heat and chemicals. Steel, cement, and power plants use these refractories. They need them to stay safe from heat and damage. The market for low cement castables is getting bigger. In 2023, it was worth USD 750 million. By 2032, it may reach USD 1.2 billion.

Learning about monolithic refractories helps people make good choices. Manufacturers and engineers can pick the best refractory for tough jobs.

Castable refractory cement is very strong and can handle heat. People use it to build and fix furnace linings in places like steel and cement factories.

Monolithic refractories come loose, so workers can pour or shape them at the job site. This makes putting them in and fixing things quicker and easier.

These materials can stand very high heat, chemicals, and damage. They help machines last longer and keep them safe when things get tough.

Monolithic refractories save energy because they keep heat inside. Their tough, jointless linings also cut down on repair time and costs.

Castable refractory cement works for many shapes and uses. It protects against heat in big factories and even home ovens. It is flexible and dependable.

Monolithic refractories are heat-resistant materials. They come loose or without a set shape. These are not like bricks with fixed shapes. Workers can mold or pour them at the job site. This makes it easy to fit tricky furnace shapes. It also helps fix broken spots fast. Monolithic refractories have tiny pores and no set form. The small pores make them strong and tough against heat and chemicals. These features help them work well in places with high heat. They also cut down heat flow by about 30% compared to bricks. The flexible linings let stress out, so cracks and breaks are less likely. Industries use these for new linings and quick fixes. The jointless lining is a big plus. It gets rid of weak spots found in brick linings. This smooth surface keeps heat in better and helps the refractory last longer.

Tip: Monolithic refractories take up less space in storage. They also help workers finish repairs faster since they come in bulk and do not need careful stacking.

People sort monolithic refractories in different ways. The main ways are by pore size, binder type, what they are made of, and how they are put in. The table below shows these groups:

| Classification Criterion | Categories / Types |

|---|---|

| Porosity | Dense monolithic refractory (heavy), Heat insulation monolithic refractory (light, porosity ≥ 45%) |

| Binder Type | Inorganic binder, Organic binder; Hardening modes: gas hardening, hydraulic, thermal, others |

| Aggregate Material | Dense aggregates (clay, alumina, magnesia), Heat insulation aggregates (pumice, vermiculite) |

| Construction Method | Castables, Spray coatings, Plastics, Ramming materials, Pressing materials, Projections, Smears, Dry vibration materials |

The main types of monolithic refractories are:

Castables: Workers pour these into molds. They get hard and make strong linings for furnaces and kilns.

Plastic refractories: These are soft like clay and easy to shape. They become heat-resistant after they harden.

Ramming mixes: Workers pack these tightly by ramming. They make tough linings for furnace bottoms and troughs.

Gunning mixes and shotcretes: These are sprayed or gunned on for quick repairs.

Patching mortars and projection materials: These fill gaps and fix small damaged spots.

Each kind of monolithic refractory has special uses. Ramming mixes work well for furnace bottoms. Plastic refractories fix odd-shaped surfaces. Castables are good for pouring and molding in many furnaces. The jointless lining gives better coverage and saves time on repairs. Industries pick these refractories for their strength, flexibility, and fast setup.

Castable refractory cement is a special kind of monolithic refractory. It mixes different materials to make a strong, heat-proof product. Makers blend refractory aggregates, powders, and a hydraulic binder. The binder is usually high alumina cement or calcium aluminate cement. This mix is a dry powder. Workers can move and store it easily. When water is added, the cement starts working. It sticks the materials together. This makes a thick, tough lining.

The table below shows how castable refractory cement is different from other monolithic refractories:

| Type | Composition | Binder Type | Typical Use/Application | Key Differences/Notes |

|---|---|---|---|---|

| Castable Refractory Cement | Refractory aggregate + refractory powder + cement or admixture | Usually aluminate cement (calcium aluminate cement) | Constructing furnace linings by pouring and molding | Hydraulic binder; no pre-calcination needed; used for building or repairing furnaces; offers construction flexibility and durability |

| Refractory Mortar | Refractory clinker powder + plastic clay | Plastic clay (binder and plasticizer) | Masonry joints between refractory bricks | Lower strength at normal temperature; gains strength after high-temperature ceramic bonding; fine particle size (<1mm) |

| Refractory Cement | Calcined bauxite and limestone clinker | Calcium aluminate clinker (hydraulic cementitious) | Used as a binder material | Obtained by calcining raw materials; mainly used as binder in refractory concrete/castables |

Each main ingredient in castable refractory cement has a job. High alumina cement is the binder. It gives the mix strength and keeps it stable. Refractory aggregates like high alumina, silicon carbide, or mullite add weight and help it handle heat and shocks. Additives such as plasticizers and dispersants make the mix easier to pour and shape. Binders like clay or colloidal silica help the pieces stick together. They also help the mix stand up to heat. Some advanced castables use magnesium oxychloride cement. This makes a bond without phosphate. It forms needle-like crystals that hold the aggregates tight. This makes the lining stronger and tougher. These features are important for hard jobs.

High alumina castable is used a lot in many industries. It uses high alumina aggregates and cement. These give it great strength against heat and chemicals. This type is found in steel plants, cement kilns, and power stations. These places need strong materials because of harsh conditions.

Castable refractory cement works by making a solid, heat-proof lining. Workers mix it with water and pour it where needed. First, they store and check the dry mix. It must stay dry so it does not clump or set too soon. Before mixing, workers get their tools ready and clean them well.

To use the castable, workers measure the dry mix. They add the right amount of water. The water starts a chemical reaction called hydration. This reaction makes the mix hard and strong. Mixing must be done well. Special mixers help make the blend even. The mix sets fast, usually in 30 minutes. Workers must work quickly.

After mixing, the castable is poured into molds or forms. The forms must be waterproof and strong. Workers may shake the mix gently. This removes air bubbles and makes the lining thick and even. After pouring, the surface is covered. This keeps moisture in and stops it from drying too fast. The lining needs several days to cure. Temperature and humidity must be watched. If it gets too hot or cold, the castable may crack or not harden right.

The last step is drying the lining. This gets rid of extra water. It gets the refractory ready for high heat. Engineers heat the lining slowly. This stops steam from building up. Too much steam can cause cracks or even explosions. If done right, the castable makes a strong, smooth lining. It protects furnaces, kilns, and other machines from heat, wear, and chemicals.

Castable refractory cement is not the same as other monolithic refractories. Refractory mortar is mostly for joining bricks. Castable makes the whole lining. It has bigger aggregates. This gives it more strength and better resistance to wear. Compared to pure refractory cement, castable can handle higher temperatures (up to 1800°C). It is stronger and lasts longer. The table below shows some differences:

| Parameter | Castable Refractory Cement | Refractory Cement |

|---|---|---|

| Maximum Service Temperature | Higher (approx. 1600–1800°C) | Lower (approx. 1400–1600°C) |

| Mechanical Strength (Cold Crushing Strength) | Higher (30–100 MPa) | Lower (20–50 MPa) |

| Thermal Conductivity | Moderate (0.8–2.5 W/m·K) | Slightly higher (1.2–3.0 W/m·K) |

| Setting Time | Longer (2–8 hours, hydraulic bonding) | Shorter (0.5–4 hours) |

| Abrasion Resistance | High (due to aggregate reinforcement) | Low (binder-only matrix) |

Note: The special mix of aggregates and binders in castable refractory cement makes it work better in places with lots of heat and wear. This is why it is used to build and fix furnaces, kilns, and incinerators.

Monolithic refractories, especially castable types, are flexible for building. Workers can pour or pump the mix into tricky shapes. This makes smooth linings with no joints. No joints means fewer weak spots. The lining lasts longer. Castable refractories also make repairs easy. Workers can patch damaged spots fast without taking out big sections.

Monolithic refractories have special features that make them important for hot jobs. These features help protect machines, keep workers safe, and make equipment last longer. Monolithic refractories can handle high heat, do not react with chemicals, and are tough and strong. They also resist breaking from quick temperature changes and from things rubbing against them. Each feature helps the refractory work better.

Monolithic refractories are great at handling very high heat. Most insulating castable refractories work well from 1600°F to 3000°F (870°C to 1650°C). This means they can be used in many furnaces, kilns, and reactors. They do not melt or fall apart when it gets really hot. This keeps the lining safe and protects the machines.

These refractories also do not react with harsh chemicals. Newer monolithic refractories use dense mixes and special additives like colloidal silica. These block strong acids, alkalis, and slags from getting in. Low cement castables and ultra-low cement castables have fewer holes and are packed tighter. This makes them even better at stopping chemical attacks in tough places. Tests show monolithic refractories can resist acid more than 95% of the time. They stay strong even when around strong chemicals. Their dense parts and special extras help stop damage from gases, liquids, and solids. This chemical strength helps the lining last longer and saves money on repairs.

How well monolithic refractories work depends on the furnace, the heat, and the chemicals they face. Picking the right refractory makes sure the lining can handle both heat and chemicals without breaking.

Monolithic refractories last a long time, which is why many industries use them. They must survive lots of heating and cooling and heavy use. Castable refractory cement, a common type, does well in tests. When tested, small cubes can hold up to 90 MPa to 170 MPa, depending on the mix and how they are heated. Low cement castables, after being heated to 1000°C, can reach about 170 MPa. This means the lining can hold heavy things and not crack.

How the refractory is cured and fired also matters. Samples cured at 20°C and 50% humidity, then dried and fired at 1100°C, stay strong and resist damage. These tests follow strict rules to make sure they are good quality. The strength comes from their tight structure and strong bonds between the pieces. This helps them stand up to wear, hits, and pressure from big machines.

Putting in the refractory the right way and taking care of it helps it last longer. Good installation means fewer joints, which are weak spots. Checking and fixing the lining often stops small problems from getting worse. Using the right patching materials and following good steps keeps the lining strong for a long time.

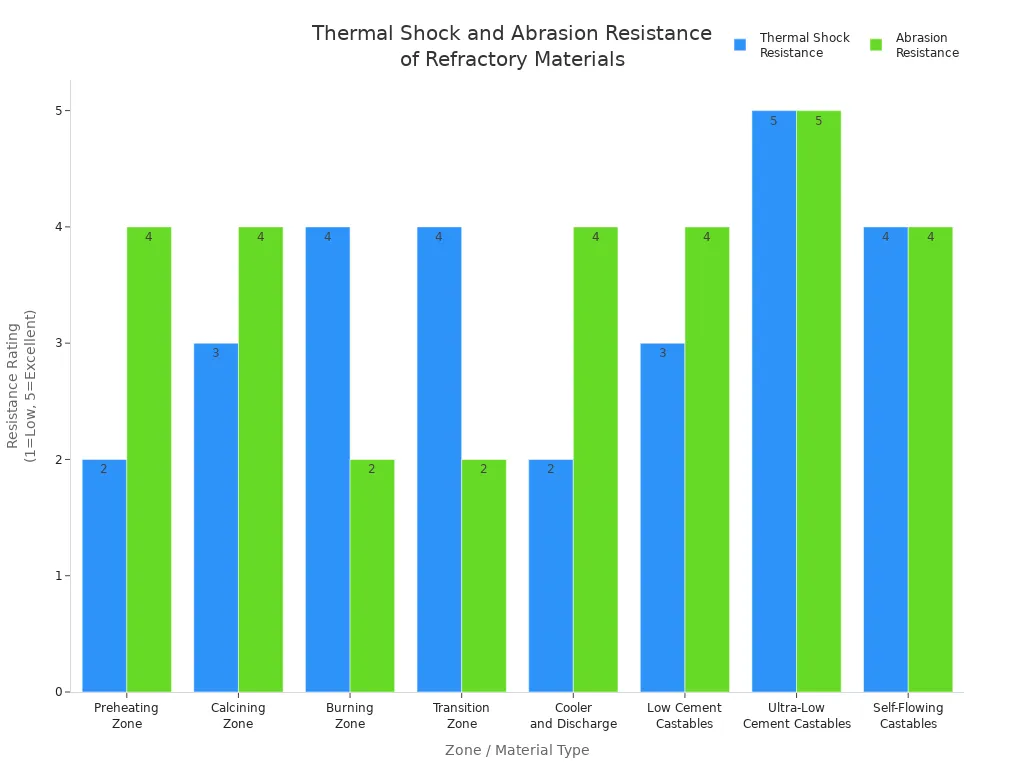

Thermal shock resistance is important for refractories that face fast temperature changes. Monolithic refractories, especially castable ones, handle these changes well. Adding things like α-Al2O3 hollow spheres and CaTiO3 helps them survive many heating and cooling cycles. These extras let the refractory take in and let out heat without cracking. Silica sol-bonded castables are packed tighter and resist damage better than older types.

Abrasion resistance is also key. Many factories have moving solids or gases that can wear down the lining. Low cement castables and ultra-low cement castables are very good at resisting this because they are packed tight and made just right. For example, low cement castables have less than 10% cement and 60% to 85% alumina. Their strength is above 70 MPa. Ultra-low cement castables have even less cement and more alumina, with strength above 90 MPa. These are good for places with lots of wear.

The table below shows how different refractory materials handle thermal shock and abrasion in different kiln zones:

| Zone/Material Type | Thermal Shock Resistance | Abrasion Resistance | Key Properties and Composition |

|---|---|---|---|

| Preheating Zone | Moderate thermal shock resistance | High abrasion resistance | Alkali-resistant, high alumina or SiC-based, Al2O3 40–70% |

| Calcining Zone | Good thermal shock resistance | High abrasion resistance | High alumina castables/bricks, Al2O3 60–70% |

| Burning Zone (Clinker Zone) | High thermal shock resistance | Moderate abrasion resistance | Magnesia-spinel or magnesia-chrome bricks, MgO 70–90% |

| Transition Zone | High thermal shock resistance | Moderate abrasion resistance | Spinel or dolomite-based refractories, MgO 40–70% |

| Cooler and Discharge Zone | Moderate thermal shock resistance | High abrasion resistance | High alumina bricks or SiC-based, Al2O3 50–70% |

| Low Cement Castables (LCC) | Good thermal shock and abrasion resistance | Good abrasion resistance | Cement <10%, Al2O3 60–85%, CCS >70 MPa |

| Ultra-Low Cement Castables | Excellent thermal shock and abrasion resistance | Excellent abrasion resistance | Cement <3%, Al2O3 70–90%, CCS >90 MPa |

| Self-Flowing Castables | High thermal shock resistance | High abrasion resistance | Cement <5%, Al2O3 60–80%, CCS >80 MPa |

Castable refractory cements with high alumina and special extras often work better than old-style bricks. Their tiny structure helps stop cracks from starting and spreading during fast temperature changes. Additives like fused zirconia-alumina and micro-andalusite make them tougher and harder to break. These features help stop spalling, which is when the lining flakes off from quick heat changes.

Light-weight castables are another good choice. They are not as heavy, so they are easier to move and put in place. They also keep heat in better, which saves energy. Their structure lets them stay strong but not heavy. Many factories use light-weight castables where insulation matters and there is not much wear.

How well monolithic refractories work depends on many things. The type of furnace, the heat, and how they are put in all matter. What they are made of, like special fibers and aggregates, helps them resist breaking and handle heat changes. Taking care of the lining with checks and repairs helps it last longer.

Monolithic refractories are easy to install. Workers can use casting, ramming, shotcrete, or gunite. Each way works for different jobs and shapes. Casting means pouring wet refractory into forms. Ramming uses tools to pack layers tightly. Shotcrete and gunite spray the mix onto surfaces. This makes repairs quick and simple. Workers control thickness and add expansion joints when ramming. This helps the lining last longer and makes fixing it easier. Monolithic refractories make jointless linings. These linings do not have weak spots like brick linings. The smooth surface stops cracks and damage from fast temperature changes. So, workers do not need to fix things as often. Repairs are easier and faster. In factories, these features save time and work. They can cut maintenance by up to 70%. This keeps machines working longer and stops downtime.

Monolithic refractories help save energy and money. Their dense structure keeps heat in and stops heat loss. This lowers energy use in hot places. It also helps companies follow environmental rules. These refractories last a long time and resist wear. Machines need fewer repairs and work longer. Steel, cement, and power plants use them to save fuel and cut costs. Advanced castable refractory cement works even better. Ultra-low cement types are more stable and resist corrosion. These materials are quick to install and need less shutdown time. This saves both time and money. More industries want these benefits, so the market is growing.

Monolithic refractories fit many shapes and uses. Workers can put them around odd shapes and in tight spots. They work well where heat stays high. This makes them good for tricky furnace designs and hard-to-reach repairs. Castable refractory cement can be poured, sprayed, or troweled. It fits custom linings easily. Factories use these refractories in cement kilns, steel ladles, and glass furnaces. Hazardous waste plants use them too. People at home use them for pizza ovens, fireplaces, and forges. Monolithic refractories work for big factories and small projects. They make strong, jointless linings in any shape. This is better than using regular bricks.

Monolithic refractories, like monolithic castable refractory cement, give strong protection in places with lots of heat. They stand up to heat, chemicals, and things that rub against them. Many industries pick monolithic refractory materials because they are easy to put in. Repairs are quick, and the linings last a long time. New studies show advanced monolithic refractory linings help save energy. They also help lower the cost of fixing machines. The table below shows important benefits for users:

| Benefit | Support for Reliability and Versatility |

|---|---|

| High thermal resistance | Durable in extreme heat |

| Chemical resistance | Reliable in harsh environments |

| Fast installation | Saves time and labor |

| Energy saving | Lowers operational costs |

Monolithic refractory cement lets factories and people at home make safe linings. These linings work well, save energy, and last for years.

Monolithic refractories keep furnaces, kilns, and reactors safe from heat and chemicals. Factories use them in steel, cement, and power plants. People at home use monolithic refractory cement in pizza ovens and fireplaces.

Monolithic castable refractory makes smooth linings with no joints. Workers pour or pump it where needed. Bricks must be stacked and have joints between them. Monolithic linings last longer and do not crack as much as brick ones.

Yes. Monolithic refractory cement is easy to fix. Workers can patch small damaged spots fast. They do not need to take out big sections. This saves time and keeps machines working. Monolithic refractory materials make repairs simple.

Monolithic refractory linings can take heat up to 1800°C. High alumina monolithic castable refractory works in very hot places. These linings protect machines in tough factory jobs.

Monolithic refractory materials are safe for home projects. People use monolithic refractory cement in pizza ovens, forges, and fireplaces. These linings stand up to heat and last a long time.