Views: 7 Author: Site Editor Publish Time: 2025-08-08 Origin: Site

To pick the right silicon carbide refractory, you need to match its features with your needs. Think about the temperature, strength, and chemicals in your project. Silicon carbide ceramics, like recrystallized silicon carbide, are strong and last a long time. Knowing how these materials work helps stop problems like cracks and bending. It also helps prevent surface damage and heat shock. These problems can make things break faster and work less well. Picking the right kind makes things work better and last longer.

Match silicon carbide ceramic features to your job needs. These features include temperature resistance, strength, and chemical resistance. This helps you get the best results.

Recrystallized silicon carbide handles heat very well. It protects against oxidation and thermal shock. This makes it good for high temperatures and harsh chemicals.

Sintered silicon carbide is strong and pure. It works for tough industrial jobs. Reaction-bonded types cost less. They are good for easier tasks.

Using the right silicon carbide refractory saves energy. It lowers maintenance and helps equipment last longer. This means you spend less and get better results.

Use a clear process to choose. List what you need. Pick the right type. Check if it fits and what it costs. Make sure it resists chemicals. Work with skilled suppliers for good results.

When you pick silicon carbide ceramics for hot jobs, you need to think about a few things. Each thing helps make sure the material works well and lasts long. These points help you choose the best one.

Temperature matters a lot when picking silicon carbide ceramics. These materials can work in heat up to 1627°C in air with oxygen. A silicon dioxide layer forms on the surface. This layer protects the material from burning up. It lets the ceramic last a long time at about 1500°C. Alumina and mullite refractories can’t handle as much heat. Silicon carbide ceramics are used when other materials get too hot.

Mechanical strength is also very important. Silicon carbide ceramics are strong at room and high temperatures. They can bend and hold up heavy loads. The table below shows some strength numbers:

| SiC Type | Flexural Strength (MPa) | Compressive Strength (MPa) | Temperature (°C) |

|---|---|---|---|

| Monolithic SiC | ~550 | ~3900 | Room Temp |

| Monolithic CVD SiC | ~443 | N/A | Room Temp |

| Molybdenum Foil Bonded | ~263 | N/A | Room Temp |

Sintered silicon carbide is the strongest. Recrystallized silicon carbide is next. Reaction-bonded silicon carbide is the least strong. Sintered types are best for tough jobs that need lots of strength.

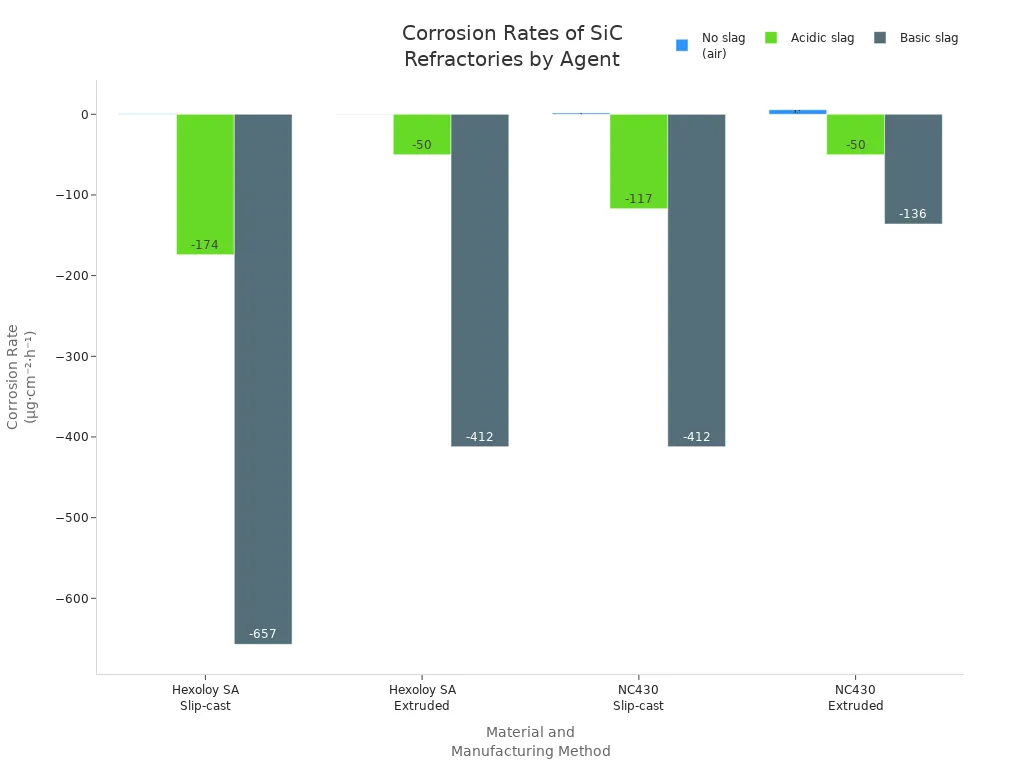

Chemical resistance is needed for many uses. Silicon carbide ceramics can stand up to lots of chemicals. But some places can hurt them. Acidic slags and gases with hydrogen or water vapor can damage the protective layer. Basic slags with iron and calcium cause even more damage. The chart below shows how fast corrosion happens in different places:

In acidic places, the protective layer stays strong. Corrosion is slow. In basic places, the layer breaks down. Corrosion gets faster. If your job has basic slags or strong chemicals, you need to be careful when picking silicon carbide ceramics.

Cost is important when choosing materials. Silicon carbide ceramics cost more than alumina or zirconia. This is because they are harder to make. But they last longer and need less fixing. They are light, so putting them in is easier and cheaper. Over time, they save money because they last longer and break less. This makes them a good choice for hot and thermal jobs.

Silicon carbide ceramics have different types. Each type has special features and uses. Manufacturers pick the best type for each job. They look at things like temperature, strength, and chemical resistance.

Reaction-bonded silicon carbide is made by mixing silicon carbide, silicon, and plasticizers. Workers shape the mix and heat it up. Molten silicon goes into the pores and reacts with carbon. This makes new silicon carbide. The ceramic has about 87% silicon carbide and 12% silicon. The table below shows its main properties:

| Property | Value |

|---|---|

| Microstructure | ~87% SiC, 12% Si |

| Density | > 3.02 g/cm³ |

| Apparent Porosity | < 0.1% |

| Maximum Use Temperature | ~1380°C |

| Flexural Strength | 250 MPa (20°C), 280 MPa (1200°C) |

| Compressive Strength | 2500 MPa |

| Modulus of Elasticity | 330 GPa (20°C), 300 GPa (1200°C) |

| Coefficient of Thermal Expansion | 4.5 x 10⁻⁶ /°C |

| Thermal Conductivity @1200°C | 45 W/m·K |

| Poisson’s Ratio | 0.2 |

| Vickers Hardness | 20-22 GPa |

Reaction-bonded silicon carbide is strong and handles heat shock well. It does not wear out or corrode easily. People use it for kiln furniture, seals, nozzles, and armor. Making it costs less and it is easy to shape. But leftover silicon means it cannot be used above 1400°C. It is hard to get high purity because of the extra silicon.

Sintered silicon carbide is made by heating silicon carbide powder very hot. This gets rid of pores and makes the ceramic dense and strong. Sintered silicon carbide is pure, hard, and has low porosity. The table below lists where it is used and why:

| Industrial Applications | Performance Advantages |

|---|---|

| Ceramic Heat Sinks | High thermal conductivity, thermal shock resistance, stability at high temperatures. |

| Ceramic Bearings | High hardness, wear resistance, chemical inertness, low porosity. |

| Military Vehicles and Bulletproof Vests | High hardness, ballistic performance, toughness, lightweight. |

| Kiln Linings | High temperature resistance, chemical stability, durability. |

| Turbine Components | High strength, thermal stability, resistance to wear and corrosion. |

| Silicon Carbide Semiconductors | High purity, excellent thermal conductivity, chemical inertness. |

| Valves (balls, seats, liners) | Wear resistance, chemical corrosion resistance, mechanical strength. |

Sintered silicon carbide is very pure and strong. It works well in tough places like reactors and furnaces. It does not corrode and keeps its shape in heat. Sintered silicon carbide lasts longer than many other materials.

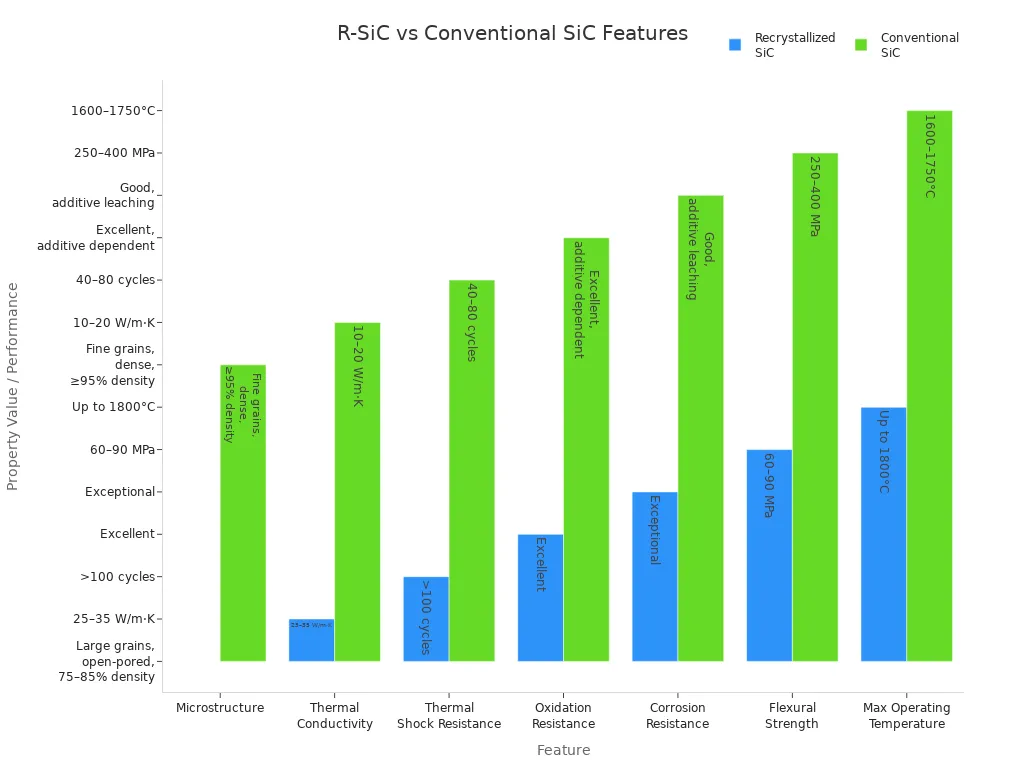

Recrystallized silicon carbide is made using a special process. Workers heat silicon carbide grains until they evaporate. Then the grains condense and join together. This makes big grains with neck growth. The ceramic has open pores, with 15–25% porosity and density around 75–85%. The chart below compares its structure and performance with regular silicon carbide ceramics:

Recrystallized silicon carbide has special features:

It has high thermal conductivity (25–35 W/m·K), much higher than most ceramics.

It can handle over 100 heat-cool cycles.

It resists oxidation because of a stable SiO₂ film.

It does not react with chemicals and resists corrosion.

It works at temperatures up to 1800°C.

Its flexural strength (60–90 MPa) is lower than sintered types, but it stays strong in heat.

Recrystallized silicon carbide is great for kiln furniture, heat exchangers, and chemical filters. Its purity and open structure help it work well in tough places. The process keeps the ceramic from shrinking and makes it stable. These features make it a top pick for high-temperature and chemical jobs.

Recrystallized silicon carbide is very strong, even when hot. This is because of its special grain structure. The grains lock together and look like plates. They grow bigger when heated above 2200°C. No extra materials are added during this process. This makes the material very hard and tough.

Pure silicon carbide, heated very hot, stays strong.

Sintered silicon carbide uses extra materials to lower heat needed. These extras can make it weaker when hot.

Recrystallized silicon carbide does not use extras. It keeps its strength better than sintered types in high heat.

The locked grains give it high bending strength and toughness.

It is used in rocket nozzles and heat shields. It stays strong and stable in extreme heat.

Recrystallized silicon carbide is stronger than other types when hot. Its purity and grain shape help it resist bending and breaking. This makes it a great pick for jobs where strength in heat is important.

Oxidation resistance is important for silicon carbide ceramics in tough places. When heated above 1200°C, a silicon dioxide layer forms on the surface. This layer stops oxygen from getting inside. It slows down more oxidation. The layer gets thicker as heat goes up. This helps protect against acids.

Silicon carbide ceramics stay safe in air up to 1600°C. The coating keeps out oxidation and chemical harm. Sintered silicon carbide is dense and resists oxidation and corrosion well. It works in both acids and bases. Reaction-bonded silicon carbide has free silicon. This does not resist oxidation as well in high heat or bases.

Recrystallized silicon carbide makes a thick silica film above 1800°C. This film protects it from more damage. It helps the material keep its shape and strength. Because of this, parts last three to five times longer than old materials. They need less fixing and break less often. In chip factories, this material keeps working in harsh gases and high heat. It lasts much longer than quartz. Its resistance to oxidation and corrosion makes it a good choice for tough jobs.

Thermal shock resistance means a material can handle quick temperature changes. It will not crack or break. Recrystallized silicon carbide is great at this. It has high thermal conductivity and low thermal expansion. Its thermal conductivity is 30 to 40 W/(m·K). This is higher than most ceramics. Its low thermal expansion, about 4.0x10^-6/°C, helps it resist stress from fast temperature changes.

| Material Type | Porosity (%) | Bending Strength (MPa) at 1200°C | Elastic Modulus (GPa) | Thermal Conductivity (W/m·K) | Thermal Shock Resistance Compared to Alumina |

|---|---|---|---|---|---|

| Recrystallized SiC | 17 | 100 | 240 | 23 | Significantly higher than alumina ceramics |

| Sintered Alpha SiC | <0.5 | 450 | 420 | 90 | About 10 times higher than alumina ceramics |

| Alumina Ceramics | N/A | N/A | N/A | N/A | Baseline for comparison |

Recrystallized silicon carbide works up to 1650°C in air. It can go up to 2000°C in special gases. It can cool quickly from 1200°C in water and not crack. This is important for kiln furniture and other hot tools. Kiln furniture made from this material does not crack during fast heating and cooling. This means fewer breaks, less fixing, and more work done. Silicon carbide saggers, especially recrystallized and reaction-bonded ones, resist cracking and bending better than alumina saggers. Nitride-bonded and recrystallized silicon carbide both show great thermal shock and wear resistance. This makes them good for hard industrial jobs.

High thermal conductivity is another key property. It lets heat move fast and evenly through the material. In furnaces, this means quicker heating and better control. Even heat makes products better and saves energy. High thermal conductivity also stops hot spots. Hot spots can cause damage or uneven wear.

Silicon carbide ceramics, including recrystallized types, move heat faster than many others. This gives several benefits:

Furnaces and reactors heat up faster.

Temperature control is better, so work is more efficient.

Less energy is used, so fuel costs go down.

Heating parts last longer and need less fixing.

In forging furnaces, high thermal conductivity keeps temperatures even. This lowers fuel use and saves money. It also helps make better products with less waste. The mix of high thermal conductivity, thermal shock resistance, and oxidation resistance makes recrystallized silicon carbide a top pick for tough jobs.

The table below shows the main properties and benefits of different silicon carbide ceramics:

| Property/Advantage | Reaction-Bonded SiC | Sintered SiC | Recrystallized SiC |

|---|---|---|---|

| Hot Strength | Moderate | High | Very High |

| Oxidation Resistance | Moderate | High | Very High |

| Thermal Shock Resistance | Good | Excellent | Excellent |

| Thermal Conductivity | High | Very High | High |

| Purity | Moderate | High | Very High |

| Abrasion Resistance | Good | Excellent | Excellent |

| Wear Resistance | Good | Excellent | Excellent |

| Corrosion Resistance | Good | Excellent | Excellent |

| High-Temperature Use | Up to 1380°C | Up to 1600°C | Up to 1800°C |

| Typical Applications | Kiln furniture, seals, nozzles | Bearings, valves, linings | Kiln furniture, heat exchangers, filters |

Tip: Always match the ceramic’s properties to your job. Recrystallized silicon carbide is best for high heat, oxidation, thermal shock, and corrosion resistance in tough places.

Recrystallized silicon carbide is pure, strong, and resists oxidation. It is very hard and resists wear. This makes it good for jobs needing both wear resistance and heat stability. Its high thermal conductivity saves energy and helps it last longer. These features make it a top choice for tough jobs in modern industry.

Picking the right silicon carbide ceramics for factories takes careful thought. You need to look at what each place needs. This guide helps you match the material to the job. It makes sure things last long and work well.

Kiln furniture holds items during firing in factories. These factories make ceramics, glass, and metal powders. Choosing silicon carbide ceramics for kiln furniture depends on a few main things.

Checklist for Matching Silicon Carbide Ceramics to Kiln Furniture:

Find out the firing temperature and air type. Most kiln furniture must handle up to 1700°C in air with oxygen.

Think about how often it heats and cools. If this happens a lot, you need ceramics that can handle quick changes.

Check if the products can get dirty. High-purity ceramics stop bad reactions with the items being fired.

Pick the bonding type. Pressureless sintered silicon carbide is the strongest and purest. Reaction-bonded types cost less for easy jobs.

Look at the shape and how it fits in the kiln. The design must fit and let the ceramic grow when hot.

Compare cost and how long it lasts. Good ceramics cost more but last longer, so you replace them less.

Make sure it works with chemicals. Strong chemicals like lithium may need coatings or dense ceramics.

Buy from trusted suppliers who offer help and custom choices.

Silicon carbide ceramics for kiln furniture have over 90% silicon carbide. They are dense (about 3.2 kg/dm³) and have very few holes (less than 0.8%). These features give them great strength. They bend at about 550 MPa and can be squeezed at 3900 MPa at room temperature. They move heat well (20-30 W/m·K), so heat spreads out evenly. They work up to 1700°C in air with oxygen, so they last a long time.

Makers say using recrystallized silicon carbide (RSIC) for kiln furniture helps a lot:

RSIC stays strong above 1600°C, better than old materials.

It does not break from quick temperature changes.

RSIC fights off damage from harsh chemicals.

Some factories saw kiln walls last 30% longer and make 15% more products after using RSIC.

RSIC lasts longer, so you fix things less and spend less money.

It moves heat well and does not grow much when hot, saving energy.

Tip: RSIC kiln furniture is stable in high heat, resists chemicals, and is pure. This makes it best for hard firing jobs and tough air.

You should also think about how easy it is to shape and use. RSIC can be made into many shapes for special kiln furniture. It is light, so it is easy to move and put in place. You do not need to fix it much because it does not bend, crack, or get damaged by chemicals. Workers should check kiln furniture often for wear, but RSIC lasts so long you do not need to replace it much.

Factories need refractories that can take very high heat, fast changes, and harsh chemicals. Silicon carbide ceramics are great for these hot jobs because of their special features.

| Key Consideration | Specification/Feature | Benefit for Furnace Applications |

|---|---|---|

| Material Composition | High-purity silicon carbide aggregates | Great at handling quick heat changes and chemicals |

| Maximum Service Temperature | Up to 1780°C | Good for very hot furnace parts |

| Thermal Shock Resistance | Superior | Less cracking and less time fixing |

| Corrosion Resistance | High | Lasts longer in tough places |

| Certification Standards | ISO, ASTM, and international certifications | Makes sure quality is always good |

| Sustainability Factors | Energy conservation and emission reduction | Uses less energy and is better for the planet |

| Proven Industry Experience | Over 20 years with global footprint | Shows the product works well everywhere |

| Real-World Case Studies | Improved efficiency, reduced downtime, cost savings | Proves the material is a good choice |

New silicon carbide ceramics in furnaces save up to 15% energy because they keep heat in. They last 25-30% longer than old materials, so you fix them less. Steel factories saw 40% fewer problems with their refractories. Glass factories are safer and work better because of less corrosion.

In one aluminum plant, switching to silicon carbide linings made heat spread out better. The time to heat up dropped by 6%. After a year, they needed to fix things less often, and energy use went down by 4%. These results show silicon carbide ceramics help you fix things less and spend less money.

Note: Furnace workers should use designs that are easy to take apart and fix. Using sensors and data helps you know when to fix things before they break, so you avoid surprise problems.

How easy it is to shape and use matters too. Silicon carbide ceramics can be made in many shapes and sizes for different furnaces. They are light, so putting them in is easy. You still need to check and change heating parts, but you do not have to fix things as much because the material is tough.

Chemical reactors work in very hot and harsh places. Picking silicon carbide ceramics for these jobs means the parts last long and work well.

A big chemical plant said their reactors lasted 40% longer after switching to recrystallized silicon carbide linings. This is better than using alumina or magnesia. RSIC fights off chemical damage and stays strong in high heat. It keeps its shape and stays clean for a long time.

Checklist for Selecting Silicon Carbide Ceramics in Chemical Reactors:

Check the reactor’s heat and what chemicals it faces.

Use high-purity ceramics for jobs where you do not want mixing.

Pick RSIC for the best chemical and heat resistance.

Make sure the shape fits the reactor.

Think about coatings for extra protection.

Pick materials that are easy to put in and fix, so you save time.

Silicon carbide ceramics are strong, have few holes, and fight off chemicals. This makes them perfect for chemical reactors. They keep working in high heat, so products stay good.

You can shape them for special reactor parts like tubes, plates, and filters. They are light, so putting them in is easy. You do not need to fix them much because RSIC does not get damaged by chemicals or heat changes.

Tip: Check reactor linings often for damage. RSIC lasts a long time, so you do not need to stop work or fix things as much. This helps factories keep running in tough jobs.

To match silicon carbide ceramics to jobs, follow these steps:

List What You Need: Write down the heat, chemicals, weight, and how often it gets hot and cold.

Pick the Material Type: Choose pressureless sintered, reaction-bonded, or recrystallized silicon carbide based on what you need.

Check Shape and Fit: Make sure the ceramic fits and can grow when hot.

Compare Cost and Life: Think about how much it costs and how long it lasts.

Check Chemical Resistance: Make sure it can handle the chemicals in your job.

Look at Supplier Experience: Pick suppliers who know what they are doing and have proof.

Plan for Use and Fixing: Choose ceramics that are easy to put in and do not need much fixing.

️ Practical Considerations:

Machinability: RSIC and other silicon carbide ceramics can be shaped for special jobs in kilns, furnaces, and reactors.

Installation: Light ceramics are easy to move and put in, so you save money.

Maintenance: They are tough and resist chemicals, so you fix them less and wait longer between repairs.

Silicon carbide ceramics work great in hot jobs. They are pure, strong, and fight off chemicals. You can use them in many places, like kiln furniture and chemical reactors. If you follow these steps, you can make things work better, stop work less, and make your equipment last longer.

Picking silicon carbide ceramics with the right features helps machines last longer and work better. Companies save money over time in these ways:

Machines last 50% longer, so you buy new ones less.

Running costs go down by 25% because things work better.

There are fewer fixes needed since the ceramics fight off rust and damage.

Experts say you should work closely with your suppliers and try out the ceramics in real jobs. Getting help and custom choices makes sure the ceramics fit your needs and work well.

RSIC Kiln Furniture means Recrystallized Silicon Carbide kiln furniture. Factories use it to hold things during firing. RSIC is very strong and handles quick temperature changes well. It lasts a long time in hot kilns.

RSIC Kiln Furniture does not bend or crack easily. It also fights off chemicals better than alumina or mullite. It lasts longer and helps save energy. You do not need to fix or replace it as much. Many factories get better products and need fewer new parts.

RSIC Kiln Furniture moves heat quickly and evenly. This makes firing faster. Products heat up the same all over. Energy use goes down. Workers say fuel costs are lower and results are more steady.

Manufacturers make RSIC Kiln Furniture in many shapes and sizes. Custom pieces fit special kiln setups. This helps save space and lets air move better. It also helps things fire more evenly.

RSIC Kiln Furniture needs very little care. Workers should check for damage after each firing. Regular checks stop surprise problems. Most people find RSIC lasts much longer than other kiln furniture.