Views: 0 Author: Site Editor Publish Time: 2025-08-24 Origin: Site

Refractory materials are very important in industries with high heat. They can handle very hot and tough conditions. Monolithic refractories do not have a fixed shape. They are easy to put in place. Many industries use them, like iron and steel, cement, and power plants. These refractories make smooth linings. They can be used quickly. This is why people often pick them instead of old shaped types. We sort them into acidic, basic, and neutral refractories. This helps companies choose the best one for each job. It keeps things safe and working well.

Monolithic refractories are heat-resistant materials. They make smooth linings with no joints. They fit into complex shapes easily. This makes them faster and more flexible to install than shaped bricks.

Acidic refractories do not get damaged by acids or high heat. They are good for glass and steel furnaces. These furnaces have acidic slags inside.

Basic refractories can handle high heat and alkaline materials. They work well in steelmaking and cement kilns. These places have very tough conditions.

Neutral refractories stay strong in both acidic and basic places. They give stability and last long in mixed or changing furnace air.

Picking the right refractory type keeps equipment safe. It also cuts down on downtime. It saves energy and helps furnaces and kilns last longer.

Monolithic refractories are heat-resistant materials. They come in bulk and do not have a set shape. Workers put them straight onto equipment or structures. The materials harden and make strong, smooth linings. Factories do not need to pre-fire or shape them. Instead, they fit the surface during installation. This makes them good for tricky shapes and filling gaps. Monolithic linings protect against heat, wear, and chemicals.

Monolithic refractories are called "unshaped refractories." They arrive as powders, pastes, or slurries. They turn solid after workers install and cure them.

Monolithic refractories and shaped refractories are different. Shaped refractories are bricks with set sizes. Monolithic refractories are put in place and take the shape of the equipment. This makes monolithic linings great for jointless surfaces inside furnaces, kilns, and reactors.

| Property Type | Monolithic Refractories | Shaped Refractories |

|---|---|---|

| Chemical Properties | - Made of refractory aggregates like alumina and aluminum silicate | - Pre-formed bricks with fixed shapes |

| - Have binders such as refractory clay or water glass | - Dense and rigid, offering high mechanical strength | |

| - Additives help with fluidity, fire resistance, and corrosion resistance | - Less adaptable to deformation | |

| Physical Properties | - Unformed, adaptable materials that can be cast, rammed, or sprayed | - Mechanically strong but less flexible |

| - Make jointless linings | ||

| - Handle thermal expansion and contraction better, so less cracking | ||

| - Flexible during construction, able to fill complex shapes |

Monolithic refractories have many important features for high-temperature jobs:

Chemical Inertness: These materials do not react with slags, gases, or molten metals. This keeps equipment safe from corrosion and chemical damage.

High-Temperature Resistance: Monolithic refractories can handle very high heat, up to 1800°C. They stay strong even in the hottest furnace areas.

Abrasion and Corrosion Resistance: The materials do not wear out easily from moving solids and liquids. This helps monolithic linings last longer in tough places.

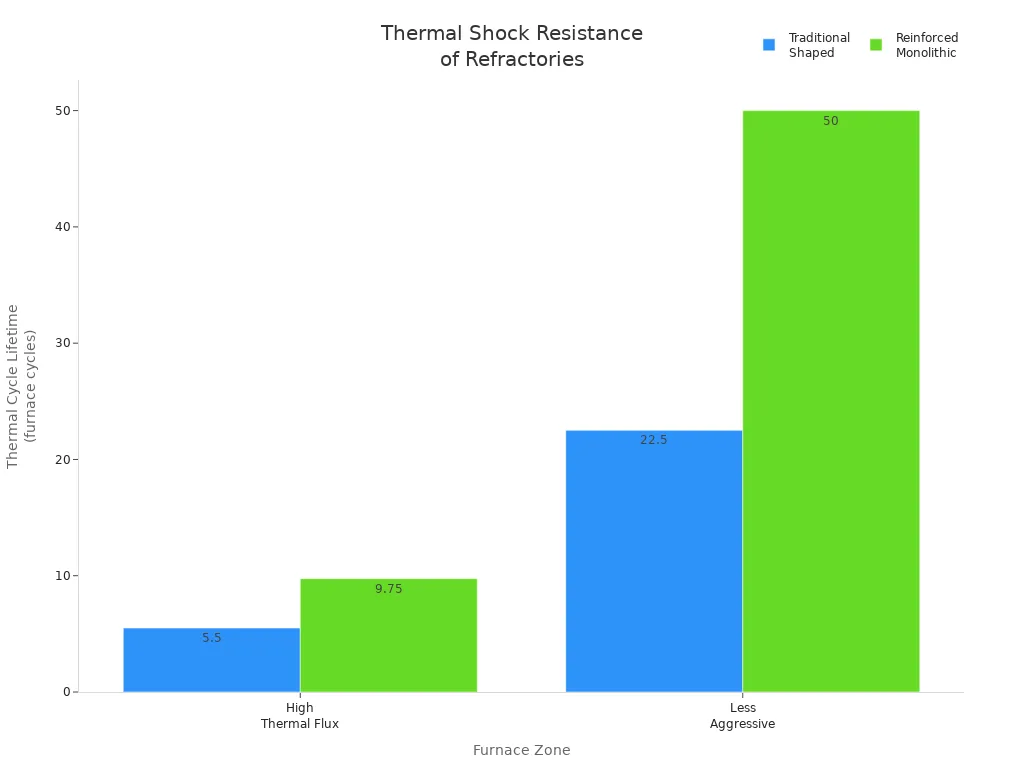

Thermal Shock Resistance: Monolithic refractories can handle quick temperature changes without cracking. Types with fiber additives are even better at this.

Seamless Linings: When installed, monolithic refractories make jointless, smooth surfaces. These linings stop weak spots where heat or chemicals could get in.

Installation Flexibility: Workers can cast, ram, gun, or spray monolithic refractories. This lets them fit any shape or fix damaged spots fast.

Monolithic linings fit complex equipment shapes. They help stop cracks from thermal expansion and contraction.

Monolithic refractories are better than shaped bricks in some ways. Workers install them faster because they go right on-site. This means less downtime and lower labor costs. The materials fill odd surfaces and gaps, making a tight seal.

New technology has made monolithic refractories stronger. Makers add nano-particles and special binders. This boosts strength, lowers porosity, and helps resist heat and chemicals. Low-cement and ultra-low cement castables work better at high temperatures.

| Feature | Monolithic Refractories | Shaped Refractories |

|---|---|---|

| Installation Time | Faster due to on-site casting, gunning, ramming, or spraying without pre-molding | Slower because of manual installation of preformed bricks or blocks |

| Cost | More economical as it eliminates pre-molding and adapts to complex shapes on-site | Higher cost due to preforming, curing, and manual installation |

Monolithic refractories are sorted by how they are installed, their porosity, binder type, and aggregate material. Each type is used for a special job in factories.

Castables: These are mixtures that workers pour into molds or onto surfaces. Castables harden and make strong, heat-resistant linings. Low-cement and ultra-low cement castables are even tougher.

Ramming Mixes: Workers pack these dense materials into place with tools. Ramming mixes make strong linings, especially in furnace bottoms and places with heavy wear.

Plastic Refractories: These soft materials are shaped by hand or machine. Plastic refractories are good for fixing odd surfaces or filling gaps.

Gunning Mixes: Workers spray these onto surfaces with special gear. Gunning mixes help with quick repairs in hard-to-reach spots.

Patching Mortars and Projection Materials: These seal gaps, fix damaged areas, and strengthen linings.

Tip: Pick the type based on the job, equipment shape, and working conditions.

| Type | Installation Method | Typical Use Cases |

|---|---|---|

| Castables | Pouring/Casting | Furnace linings, ladles, kiln hoods |

| Ramming Mixes | Ramming/Compacting | Furnace bottoms, tap holes |

| Plastic Refractories | Hand/Machine Shaping | Repairs, patching, irregular surfaces |

| Gunning Mixes | Spraying/Gunning | Quick repairs, vertical or overhead surfaces |

| Patching Mortars | Troweling/Hand Application | Sealing joints, localized repairs |

| Projection Materials | Spraying/Projecting | Surface coatings, insulation layers |

Monolithic refractories are also sorted by porosity (dense or insulating), binder type (hydraulic, ceramic, chemical, or organic), and aggregate (clay, alumina, magnesia, or light materials like pumice). International rules like ISO1927-75 help with these groups.

Monolithic linings are now the top choice in many industries. They are used most in iron and steel, cement, and glass making. Companies like Vesuvius, RHI Magnesita, and Saint-Gobain work on new ideas to make them better and greener.

Note: Monolithic refractories help lower CO2 emissions compared to old bricks. Cleaner ways to make them and recycling help the environment.

Monolithic refractories have many benefits over shaped bricks:

Quick Installation: Workers put monolithic linings on-site, so repairs are faster.

Reduced Downtime: Fast installation means furnaces and kilns are out of service for less time.

Cost-Effectiveness: No need for pre-molded bricks, so costs are lower.

Adaptability: Monolithic refractories fit any shape, so they work well for tricky equipment.

Improved Performance: Reinforced monolithic linings last longer and do not crack easily, even with lots of heating and cooling.

In hot zones, reinforced monolithic refractories can last twice as long as bricks. They have fewer problems.

Monolithic linings also help the environment. Making them uses less energy and makes fewer pollutants than bricks. Recycling old refractories cuts waste and saves resources.

Installing monolithic refractories needs careful work. Workers must watch water quality, temperature, and mixing time. Skilled installers use special tools for casting, gunning, or ramming. Good formwork stops leaks and keeps linings strong.

Safety Tip: Workers should wear safety gear, keep air moving, and follow safety rules when installing.

Labs use standard tests like ASTM C417-21 to check thermal conductivity and other features. Other tests check how well monolithic refractories resist metal, abrasion, and thermal shock. These tests make sure linings meet standards and work well.

The market for monolithic refractories has grown a lot in the last ten years. Steel, cement, and glass industries need more of them. New technology, like nano-particle additives and low-cement castables, makes them better. Rules for the environment and recycling also change how monolithic linings are made.

Acidic refractories are strong in places with acids. They have lots of silica and alumina in them. These materials do not react with acidic slags or gases. They keep their shape and strength when it gets very hot. Acidic refractories do not break from quick temperature changes. They also do not get damaged by acids. But they can get weak if they touch basic materials like lime. This happens more when it is hot. Their special properties make them good for places with acids.

Acidic refractories work best where there are acids. They last longer because acids do not harm them. This means better results and less waste.

People use silica, alumina, and fire clay to make acidic refractories. Silica refractories have over 93% silicon dioxide. Alumino-silicate and fireclay bricks are used a lot too. Some products have zirconium dioxide and quartz. These things make the refractories strong and able to take heat. They also help stop damage from acidic slags and gases.

| Material | Main Component(s) | Typical Use |

|---|---|---|

| Silica Brick | Silicon Dioxide (SiO2) | Glass tank furnaces |

| Fireclay Brick | Alumino-silicate | Steel and cement kilns |

| Quartz | Silicon Dioxide (SiO2) | Furnace linings |

Factories use acidic refractories in many hot jobs. Steel, glass, and cement plants need them for their furnaces. Acidic refractories line blast furnaces and glass-melting tanks. Their strength and acid resistance protect equipment from harm. They also help save energy by keeping heat inside. In 2023, acidic and neutral refractories made up about 55% of the market. This shows they are very important today.

Acidic refractories help keep steel and glass plants safe. They work well in high heat, so many factories use them.

Basic refractories are strong against alkaline materials. They have a lot of magnesia or dolomite. These refractories work well in places with lots of basic materials, like steelmaking and cement kilns. Their features help them do well in tough jobs:

They move heat well, so furnaces heat up fast.

They can handle very high temperatures without melting.

They are strong and can take heavy loads and hits.

They do not wear out fast when things move over them.

They do not crack easily when the temperature changes quickly.

How many holes they have affects how well they insulate and resist chemicals.

They stay stable when they get hot or cool down.

Basic refractories keep working well even in very hot and rough places. Their strength and toughness make them a good pick for many factories.

People use different raw materials to make basic refractories. The main ones are magnesia and dolomite. These give the refractories their special strengths.

| Raw Material | Typical Chemical Composition | Notes |

|---|---|---|

| Magnesia (Magnesite) | Mainly MgO (magnesium oxide) | Used for steelmaking due to high purity |

| Dolomite | CaO and MgO (CaMg(CO3)2) | Used for basic linings and aggregates |

| Fireclay | Kaolinite (Al2O3·2SiO2·2H2O) | Used in alumino-silicate refractories |

| Bauxite | High Al2O3 content | More common in high alumina refractories |

Magnesia comes from magnesite that is heated or melted. Dolomite has both calcium and magnesium oxides. These help basic refractories fight off damage from basic slags and gases.

Basic refractories are very important in metal factories. They line kilns, furnaces, and containers that get very hot. These refractories must keep their shape and strength even when it is very hot. They also need to stand up to damage from melted metals, slags, and gases.

Steelmaking uses basic refractories in converters, electric arc furnaces, and ladles.

Cement plants use them in rotary kilns and coolers.

Non-ferrous metal industries use them for smelting and refining.

Picking the right basic refractories helps furnaces work better and last longer. They help factories stay safe and work well by stopping wear, cracks, and chemical damage.

Neutral refractories stay strong in both acidic and basic places. They do not react with slags. This makes them good when the furnace atmosphere changes. These refractories can be oxides or carbon types. Chromite and synthetic graphite are two common kinds. Chromite melts at a very high temperature and stays strong above 1900°C. Carbon refractories, like anthracite, resist chemicals and work well when there is less oxygen. Neutral refractories also do not crack easily from fast temperature changes. They are tough against wear.

Stay strong in acid and base conditions

Do not react with slags or gases

Keep strength at high heat

Resist cracks from quick heat changes

| Aspect | Details |

|---|---|

| Chemical Stability | Stable in both acidic and basic environments |

| Typical Composition | Alumina, Chromium oxide, Ferric oxide, Carbon |

| Performance | Prevents damage in mixed environments |

| Applications | Electric arc furnace roofs, ladles, cement kilns, crucibles |

| Advantages | Versatile, stable, resists heat shock, resists wear |

Neutral refractories help factories when acids and bases mix. Their many uses make them a smart pick for lots of jobs.

Makers use alumina, chromia, and carbon to make neutral refractories. These materials are very pure and strong. Alumina refractories have about 92% Al₂O₃. They are dense and do not shrink much. Chromia refractories use chromium oxide for more chemical strength. Carbon refractories, like graphite, do not rust and keep their shape in heat. When picking materials, people look at chemical makeup, how much they expand, how tough they are, and how much weight they can take.

| Material Component | Typical Percentage | Physical/Chemical Property | Value/Description |

|---|---|---|---|

| Alumina (Al₂O₃) | ~92% | Density | 1.75 Kg/cm³ |

| Silica (SiO₂) | ~1% | Water content per 50Kg | 6-7 L |

| Iron Oxide (Fe₂O₃) | ~0.3% | Shrinkage (casting/drying) | 0 |

| Calcium Oxide (CaO) | ~4.6% | Shrinkage rate at 1310°C | 0.002 |

| Titanium Dioxide (TiO₂) | ~1.8% | Maximum temperature | 1760°C |

Graphite refractories are good in metal furnaces if you can control oxygen. High purity helps neutral refractories last longer and work better.

Neutral refractories are used in many factories. Steel plants put them in electric arc furnaces and ladles. Cement factories use them to line kilns. Chemical and oil plants use them for crucibles and reactors. Glass makers use them to stop damage from hot glass above 1600°C. Their heat strength helps furnaces work well and need fewer repairs. Neutral refractories help furnaces last longer and save energy. Factories in Asia Pacific, Europe, and North America trust these refractories for good results.

Neutral refractories help keep glass clean and cut repair costs. Their strength and stability are needed for hot jobs.

Knowing what makes monolithic refractories special helps factories keep machines safe. It also helps them work better. Picking acidic, basic, or neutral types depends on what chemicals are around. It also depends on what the job needs. The table below shows which type works best for each job:

| Type | Best Use | Main Strength |

|---|---|---|

| Acidic | Glass furnaces, coke ovens | Resists acidic slags |

| Basic | Steelmaking, cement kilns | Handles basic slags, high heat |

| Neutral | Mixed environments, buffer zones | Stable in both conditions |

If you pick the right refractory, it lasts longer. You get less downtime and save more energy.

Monolithic refractories protect furnaces, kilns, and reactors from heat. They make strong linings that do not have seams. These linings stop wear and chemical damage. Many factories use them because they go in fast. They also fit equipment with tricky shapes.

Monolithic linings are strong and do not react with chemicals. They can handle quick changes in temperature. These features help the linings last longer. They also keep machines safe. The smooth design stops weak spots. This makes them work better in hard jobs.

There are several main types of monolithic refractories. These include castables, ramming mixes, plastic refractories, and gunning mixes. Each type is good for different jobs and ways to install. Workers pick the right one for the job and what is needed.

Factories like monolithic refractories because they go in faster. This means less time when machines are off. These materials fit any shape of equipment. Monolithic linings also handle heat changes better. This means fewer cracks and they last longer.

Refractories use special materials and smart designs to stay strong. Their features help them fight off damage from heat and chemicals. They also stand up to quick temperature changes. This keeps furnaces and other machines safe and working well.