Views: 0 Author: Site Editor Publish Time: 2025-08-27 Origin: Site

Refractory bricks and normal bricks are not the same. Refractory bricks have a lot of alumina and silica. This helps them handle very high heat, over 1500°C, without getting weak. Normal bricks are mostly made from clay. They cannot take such high heat and might break at lower temperatures. Picking the right brick is important. Using the wrong brick can make things unsafe or cause buildings to fail in hot places. Refractory bricks do not let heat pass through easily. They are also very strong and do not get damaged by chemicals. This is why people use them in furnaces, kilns, and other tough jobs.

Refractory bricks have special minerals like alumina and silica. These minerals help them handle very high heat. They also help them resist chemicals. Normal bricks are mostly made from clay.

Refractory bricks keep heat inside furnaces and kilns. This helps save energy. They last longer in hot and tough places.

Normal bricks are good for building walls and houses. But they break easily when there is high heat. They also break when exposed to chemicals.

There are different types of refractory bricks for different jobs. Some work in acid, basic, or neutral places in factories and homes.

Using the right type of brick keeps things safe. It also makes things last longer and saves energy in factories and homes.

Refractory bricks do not have many colors. Most are a yellowish-white shade called buff. Some look ivory with black spots. Others are red with buff spots. Makers sometimes add a matte glaze. This gives the bricks a solid color like dark red, gold, black, slate grey, or grey limestone. The surface feels rough. You can see small spots or specks. This roughness comes from special materials. These materials help the bricks stand up to heat. The color and texture make it easy to spot refractory bricks in kilns or fireplaces.

Normal bricks come in many colors. Most people know the red or orange ones. But normal bricks can also be white, brown, or grey. The color depends on the clay and minerals used. Some normal bricks have a smooth surface. Others feel rough or have tiny patterns. Builders may add a glaze or coating. This changes the color or finish. The many colors and textures make normal bricks good for walls and houses. People care about how these bricks look.

The table below shows how refractory bricks and normal bricks look different:

| Feature | Refractory Bricks | Normal Bricks |

|---|---|---|

| Common Colors | Buff, ivory, red with flecks, gold, black, grey | Red, orange, brown, white, grey, custom colors |

| Surface Texture | Rough, dense, matte glaze, flecked | Smooth, rough, micro-relief, glazed |

| Appearance Uniformity | More uniform, specialized look | More varied, rustic or decorative |

| Typical Use | Kilns, furnaces, fireplaces | Walls, buildings, general construction |

Note: Refractory bricks look more solid and even. They need to handle high heat. Normal bricks show more color and texture changes. This makes them better for decoration.

Refractory bricks are made with special materials. These materials help them survive very high heat and tough conditions. Makers pick fire clay, alumina, silica, magnesia, and other minerals for their special traits. Fire brick has a lot of alumina and silica. These minerals make the brick strong and stop it from melting. Silicon-alumina series refractory bricks mix silica and alumina for extra strength. Some fire bricks have magnesia or zirconium to last longer. Carbon-containing refractory bricks use carbon to fight off chemicals and heat shock. Zirconium-containing refractory bricks add zirconia to handle even hotter places.

The table below shows what is in refractory bricks and normal bricks:

| Brick Type | Primary Raw Materials | Key Characteristics and Differences |

|---|---|---|

| Refractory Bricks | Silica (SiO2), Alumina (Al2O3), Mullite, Corundum, Zirconium, Carbon | High alumina content (up to 90%+), mineral phases like mullite and corundum, designed for high thermal resistance and high-temperature applications |

| Ordinary Bricks | Soil or clay | Mainly composed of clay minerals, reddish-brown or gray color, lower temperature resistance, used for general construction |

Alumina and silica help fire bricks stand up to heat over 1500°C. Magnesia lets the brick take even more heat, up to 2200°C. These minerals also keep the brick safe from chemicals and damage. Insulating refractory bricks use light materials to hold in heat and save energy. The density of refractory bricks is not always the same. Light bricks have more holes and are not as strong. Heavy bricks are thick and very strong. This changes where each type is used.

Tip: Fire bricks with lots of alumina or magnesia are best for places with strong heat and chemicals, like steel plants or glass kilns.

There are many kinds of refractory bricks. Each kind is made for a certain job. The most common types are acid refractory bricks, basic refractory bricks, and neutral refractory bricks. Acid refractory bricks, like silica bricks, have up to 95% silica. These bricks can handle acid slags and gases and work well in glass furnaces. Ganister bricks are also acid bricks, with about 85% silica, plus clay and lime.

Basic refractory bricks use magnesium oxide and iron oxide. Magnesite bricks have about 85% magnesia and 3-5% iron oxide. Dolomite bricks have calcium carbonate. Bauxite bricks use about 86% bauxite. These bricks can handle alkaline stuff and are used in steel plants and cement kilns. Alkaline series refractory bricks do well in basic places.

Neutral refractory bricks balance alumina and silica. Chromite bricks have about 50% chrome iron ore. Carborundum, spinel, and chrome magnesite bricks are also neutral. These bricks go between acid and basic linings and give balanced chemical safety. High-alumina refractory bricks can take weak acids and alkalis and handle heat shock well. Silicon-alumina and silica-alumina refractory bricks mix silica and alumina for good results.

The table below lists the types of refractory bricks and their features:

| Type of Refractory Brick | Key Composition | Performance Characteristics |

|---|---|---|

| Acid Refractory Bricks | High silica content (e.g., Silica bricks ~93-95% SiO2, Ganister bricks ~85% silica + clay + lime) | Good for acidic places, high melting points, can take heat up to ~2000°C, but not good with fast temperature changes |

| Basic Refractory Bricks | High in magnesium oxide and iron oxide (e.g., Magnesite bricks ~85% MgO + 3-5% Fe2O3, Dolomite bricks with calcium carbonate, Bauxite bricks with ~86% bauxite) | Strong against corrosion and chemicals, great for basic slag linings, can take heat ~1400-1600°C |

| Neutral Refractory Bricks | Balanced composition including chromite, carborundum, spinel, chrome magnesite (e.g., Chromite bricks ~50% chrome iron ore) | Used between acid and basic linings, have balanced chemical safety and heat stability |

Yufeng Refractory makes many kinds of fire bricks and refractory materials. Their products include insulating refractory bricks, high-alumina refractory bricks, silica-alumina refractory bricks, and carbon-containing refractory bricks. Yufeng's fire bricks are dense, have few holes, and can handle heat shock well. The company uses new technology to make bricks that last a long time and have even structure. Their insulating refractory bricks help save energy by keeping heat inside furnaces and kilns. Yufeng also makes zirconium-containing refractory bricks for the hardest jobs.

Note: The right refractory brick depends on the heat, chemicals, and stress in each job. Acid refractory bricks are best for glass furnaces. Basic refractory bricks are good for steelmaking and cement kilns. Neutral bricks are used in non-ferrous metal smelting and petrochemical plants.

Normal bricks, or clay bricks, are made from natural clay and shale. These bricks have much less alumina and magnesia than refractory bricks. The clay gives normal bricks their red-brown or gray color. Builders use normal bricks for walls, houses, and other buildings that do not get very hot. Normal bricks cannot take high heat or strong chemicals. With less alumina and magnesia, they melt or crack in tough places.

The table below compares what is in normal bricks and refractory bricks:

| Brick Type | Typical Chemical Composition | Key Characteristics and Applications |

|---|---|---|

| Normal (Clay) Bricks | Mainly natural clay and shale | Less alumina and magnesia; not good for high heat or chemicals; used in regular buildings. |

| Acid Refractory Bricks | High silica (SiO2) content | Made to resist acid slags and gases; used in glass furnaces and acid places at high heat. |

| Basic Refractory Bricks | High magnesia (MgO) and dolomite (CaMg(CO3)2) | High melting point; great against alkaline stuff; used in steel plants and cement kilns. |

| Neutral Refractory Bricks | Balanced alumina (Al2O3) and silica (SiO2) | Good against both acid and basic places; used in non-ferrous metal smelting and petrochemical plants. |

Normal bricks have densities around 1.8 to 2.0 g/cm³. Refractory bricks can be light or heavy. Light bricks have lower density and more holes, so they insulate but are not strong. Heavy refractory bricks are dense, have fewer holes, and are stronger. Builders use heavy bricks where there is gas or liquid that can wear them down.

Alumina in refractory bricks makes them last longer, stay stable, and handle heat shock.

Silica helps bricks survive acid places and high heat.

Magnesia gives bricks strength at very high heat and protects from alkaline damage.

The purity and grain size of refractory materials change how well the brick works. Cleaner and bigger grains make bricks stronger and better against damage.

Normal bricks do not have these special features. They are good for regular building but fail in hot or harsh places. Refractory bricks, like fire bricks, protect kilns, furnaces, and other hard jobs.

Block Quote: Refractory bricks use special minerals and new technology to work where normal bricks cannot. Their special makeup makes them needed for jobs with lots of heat and chemicals.

Refractory bricks work very well in hot places. They can take heat from 1000°C to 1390°C. Some types, like high alumina or silicon carbide bricks, can handle up to 1700°C or 1800°C. This makes them perfect for steelmaking and glass factories. They are also used in other jobs with lots of heat. The alumina and silica in these bricks help them stay strong. They do not melt, crack, or change shape, even after many years.

Refractory bricks keep their shape and strength in high heat.

They do not crack easily when heated and cooled many times.

These bricks last for decades in tough places like furnaces and kilns.

Special minerals like kaolin, alumina, and silicon carbide help them fight chemicals and wear.

The table below shows how different bricks handle heat:

| Brick Type | Temperature Resistance (°C) | Typical Application Domain | Key Characteristics and Suitability |

|---|---|---|---|

| Refractory Bricks | Above 1000°C (up to 1700-1800°C) | Industrial (steelmaking, glass manufacturing, furnace linings) | High strength, high density, withstand extreme heat without deforming |

| Fire Clay Bricks | Lower than refractory bricks (suitable for lower temps) | Residential (fireplaces, chimneys, ovens) | Suitable for low-temperature applications, less durable at high heat |

| Insulating Fire Bricks | Below 1400°C | Industrial kilns, furnaces (for insulation) | Lower refractoriness but better insulation, lower density |

| Silica Bricks | High thermal stress tolerance | Industrial (glass melting furnaces, coke ovens) | Heat resistant, suitable for high thermal stress environments |

Refractory bricks meet strict fire safety rules. The ASTM C 27—98 (2008) standard sets the rules for these bricks. This standard is part of the International Building Code® and International Residential Code®. These rules show that refractory bricks are safe for hot jobs.

Normal bricks, also called clay bricks, cannot take high heat. They can handle up to about 1150°C, but they get weak and break at lower heat than refractory bricks. Normal bricks have regular clay and iron-rich shale. These do not make the bricks strong against heat. When heated and cooled many times, normal bricks crack, break, or fall apart.

Normal bricks do not spread heat evenly, which causes stress.

Uneven heat makes the brick crack or split.

After many heating cycles, normal bricks may break completely.

These bricks bend or break easily at high heat and are not good for hot jobs.

Normal bricks do not have the special minerals found in refractory bricks. They cannot fight chemicals or heat shock. Builders use normal bricks for walls and houses that do not get very hot.

Temperature resistance is important when picking bricks for a job. In factories like steel plants and glass factories, the inside gets very hot. Only refractory bricks can survive without losing strength or shape. Their heat resistance keeps equipment and workers safe from fire and damage.

In homes, fireplaces and chimneys need bricks that can take heat, but the heat is much lower. Fire clay bricks work well here. They cannot replace refractory bricks in hot factories. Using the wrong brick in a hot place can cause dangerous breaks, expensive repairs, and accidents.

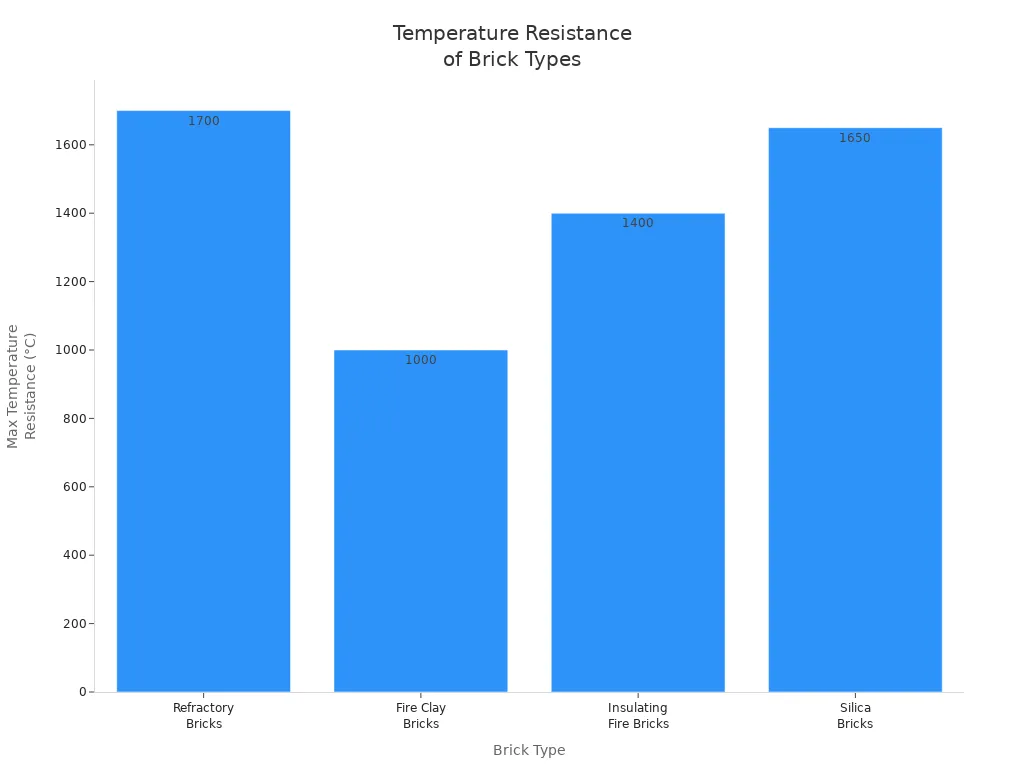

The chart below shows how different bricks resist heat:

Note: Refractory bricks protect and last longer in hot places. They keep their shape and safety for years. Normal bricks may break quickly in the same heat.

Temperature resistance also helps save energy and money. Refractory bricks stop heat from escaping in furnaces and kilns. Their long life means fewer replacements and less work. Good installation and care can make refractory bricks last even longer. This makes them a smart choice for hot jobs.

Refractory bricks do not crack or break from heat shock.

They handle stress, shaking, and hits better than normal bricks.

Bad installation or care can still make them fail early, so proper care is needed.

Factories use refractory bricks to line furnaces and protect machines. These bricks stop heat and chemicals from causing damage. Steel plants put fire brick in blast furnaces, ladles, and converters. These places get hotter than 1300°C. Cement kilns need different fire bricks in each part. Fireclay bricks go in the preheating area. High alumina bricks are used in the burning zone. Silica bricks are for the cooling area. Glass factories pick silicon carbide bricks. These bricks move heat well and do not wear out fast. Petrochemical plants use magnesia bricks. These bricks handle heat and stress from machines. Refractory bricks help furnaces last longer and need fewer repairs. They also help save energy. Yufeng Refractory makes many types of fire bricks. They have high alumina, magnesia, and insulating fire bricks. Each type fits a special job in factories. Their bricks help factories keep products good and lower repair costs.

Refractory bricks keep furnaces safe and working well, even when it is very hot.

People use fire brick in fireplaces, wood stoves, and pizza ovens. Hard fire bricks are made from fireclay with alumina and silica. These bricks go in the firebox and where the flames touch. They can take heat up to 3150°F and do not crack from heating and cooling. Soft insulating fire bricks go on the outside layers. They keep heat in and help fires burn better. Fire bricks last longer and work better than normal bricks in these places. Yufeng Refractory sells both dense and insulating fire bricks for homes. Their bricks make fireplaces and stoves safe and work well.

| Type of Fire Brick | Use in Home Settings | Advantage Over Normal Bricks |

|---|---|---|

| Hard (Dense) Fire Brick | Fireboxes, direct flame areas | High heat resistance, durability |

| Soft (Insulating) Fire Brick | Insulating liners, outer layers | Better insulation, improved heat retention |

Normal bricks are made from clay, sand, and lime. Builders use them for walls, building bases, and walkways. These bricks are strong and last long in houses and buildings. But they cannot take high heat or strong chemicals. If they get too hot, normal bricks crack and break fast. They cost less than fire bricks and refractory bricks. This makes them good for regular building but not for hot or factory jobs.

Normal bricks are good for homes and walls but break in hot places where fire bricks and refractory bricks are needed.

Refractory bricks work well in factories and homes. They give strong thermal insulation. These bricks have lots of tiny air pockets inside. The air pockets slow down heat movement. This keeps furnaces, kilns, and fireplaces hot inside. The outside stays much cooler. Less heat escapes, so less fuel is needed to stay warm.

Factories like steel plants and glass makers use refractory bricks. They want to save energy and spend less money. The bricks help machines get hot faster and stay hot longer. This means less energy is needed to start or stop machines. In homes, fire bricks in stoves and fireplaces keep heat in. Rooms stay warmer and safer. Builders and engineers like these bricks. They help protect people and equipment from burns or fires.

Insulating fire bricks are light and full of holes. Their design keeps heat in the right place and saves energy.

Thermal conductivity shows how much heat passes through a brick. Lower numbers mean better insulation. Refractory bricks, especially insulating ones, have lower thermal conductivity than normal bricks. This helps stop heat from escaping.

| Brick Type | Typical Thermal Conductivity (W/m·K) |

|---|---|

| Common Red Brick | ~0.6 |

| Insulating Brick | ~0.15 |

| Fireclay Bricks | 1 - 3 |

| High-Alumina Bricks | 2 - 5 |

| Lightweight Silica Brick | ~0.35 |

Normal bricks, like red bricks, lose heat faster. They have higher thermal conductivity. Refractory bricks, like insulating fire bricks, keep heat inside furnaces and kilns. This saves energy and lowers fuel bills. In hot jobs, these bricks do not crack or break easily. This keeps workers and machines safe.

Refractory bricks help save energy in factories and homes.

They keep heat where it is needed and stop burns or fires.

Normal bricks cannot give the same safety or energy savings.

Refractory bricks have special materials like alumina and silica. These bricks can take very high heat. They do not get hurt by chemicals. They also keep heat inside and do not let it out.

Normal bricks are made from clay. They cannot stand up to high heat. They break or crack in tough places.

Factories and fireplaces need refractory bricks to stay safe. These bricks last a long time. Normal bricks are used for walls and sidewalks in regular buildings.

Picking the right brick keeps machines safe. It saves energy and stops damage when things get very hot.

A refractory brick has special minerals like alumina and silica. These minerals help it stand up to very high heat. Normal bricks are made from regular clay. They cannot take strong heat and will break. Refractory bricks also fight off chemicals and last longer in hard places.

No, normal bricks will break or crack in high heat. Refractory bricks are better for fireplaces because they can take direct flames. They also handle being heated over and over. Using the right brick keeps your fireplace safe and strong.

Factories use refractory bricks in furnaces, kilns, and steel plants. People at home use them in fireplaces, wood stoves, and pizza ovens. These bricks protect machines and keep heat where it is needed.

A refractory brick can last for many years, even in tough places. Its special materials help it fight heat, chemicals, and damage. If you install and care for them well, they last even longer.

No, there are different kinds of refractory bricks. Some are good against acids, some against bases, and some for neutral places. Each kind has its own mix of minerals for special jobs.