Views: 0 Author: Site Editor Publish Time: 2025-08-24 Origin: Site

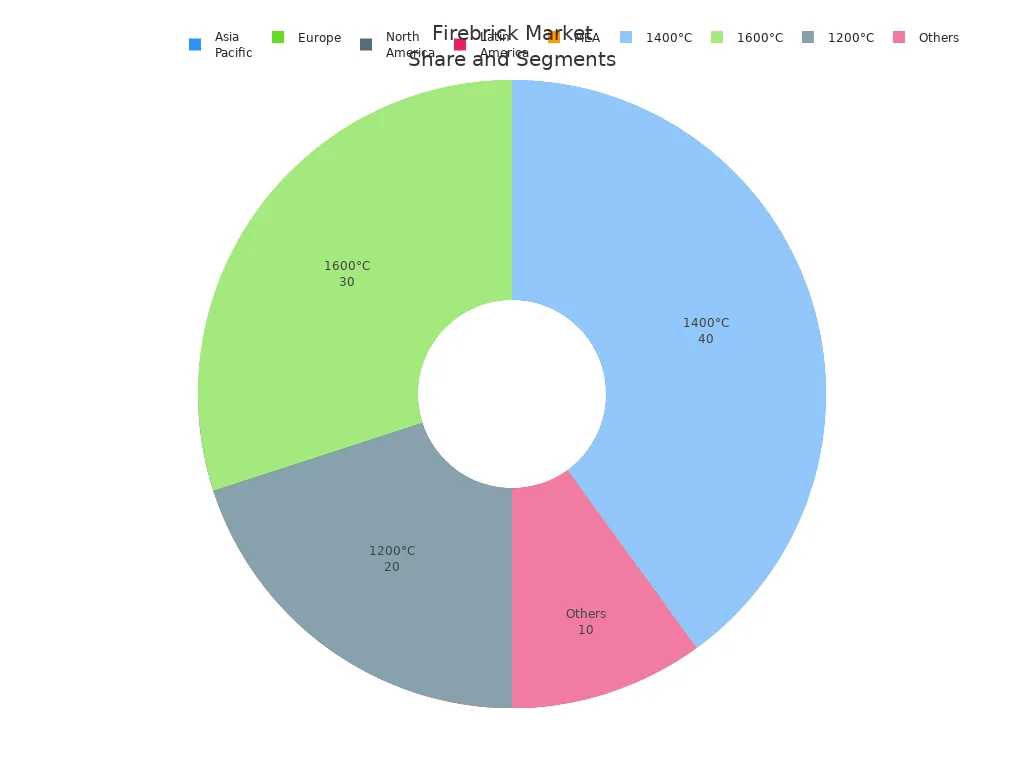

Firebricks and insulating bricks have different roles in high-temperature environments. Firebricks are made from heavy materials that make them strong and capable of withstanding direct flames. On the other hand, insulating bricks are crafted from light, porous materials that trap air and prevent heat transfer. This quality helps machines conserve energy and maintain safety. Many industries, including steel, glass, and petrochemicals, rely on insulating bricks because they effectively retain heat and improve energy efficiency. The demand for insulating bricks is especially high in the Asia Pacific region, where industrial use is widespread.

Choosing the right type of brick ensures safety and enhances machine performance across various applications.

Firebricks are thick and very strong. They can take direct flames and hold heavy things. Insulating bricks are light and full of tiny holes. They are made to keep heat in and save energy.

Insulating bricks have lots of small holes inside. These holes slow down how fast heat escapes. This makes them good for keeping kilns and furnaces hot. They also help use less fuel.

Firebricks last a long time and do not wear out fast. Insulating bricks are easier to cut and put in place. This is because they are lighter and softer.

You should pick the right brick for your job. Use firebricks if you need strength or if the brick will touch flames. Use insulating bricks if you want to save energy and keep heat in.

Insulating bricks help save money by lowering energy bills. They also make equipment safer by keeping the outside cooler. They help the environment stay clean, too.

Fire bricks are a common type of refractory brick. They are used for high-temperature insulation. These bricks are made from fireclay, alumina, and sometimes mullite. First, manufacturers pick special clays like kaolinite. This helps remove iron and other minerals. Removing these makes the brick better at handling heat. Fire bricks do not have pore-forming additives. Because of this, they are dense and strong with few pores. Their dense structure gives them high strength. This makes them good for touching flames and holding heavy things.

Fire bricks are found in furnaces, kilns, and fireplaces. They are needed where strength and heat resistance matter.

A fire brick usually has up to 20% alumina. If there is too much alumina, the brick can become unstable at very high heat. How the brick is fired also changes its density and strength. Fire bricks are denser and conduct heat better than insulation bricks. This means they are not as good at keeping heat in. But they are great for support in hot places.

Insulating fire bricks are also called insulation bricks or insulating fire brick. They are a special kind of refractory brick for high-temperature insulation. These bricks are made from pure clays, alumina, and silica. During making, things like sawdust, polystyrene, or paper waste are added. When the bricks are fired, these things burn away. This leaves many small holes inside.

This makes the bricks light and full of pores.

Insulating fire bricks can have up to 65% porosity, which lowers their bulk density a lot.

The many pores make these bricks very good at stopping heat from passing through.

| Feature | Firebricks | Insulating Fire Bricks (IFBs) |

|---|---|---|

| Primary composition | Fireclay, alumina, mullite (low) | Diatomite, perlite, vermiculite, fireclay, kaolin, alumina |

| Porosity | Low, dense structure | High (45%-90%) from pore-formers |

| Density | High | Low |

| Thermal conductivity | High | Very low |

| Pore-forming additives | Absent | Present (burn out during firing) |

Insulating fire bricks are not as strong as fire bricks. But they are great at keeping heat in. Their light and porous build makes them good for lining kilns and furnaces. They are used where saving energy is important. Some insulating fire bricks can handle heat up to 1800°C. This makes them a top pick for high-temperature insulation.

Insulating bricks and insulation bricks are often used with dense bricks. This helps balance insulation and strength.

Density is a very important property for refractory bricks. Fire bricks are dense and strong. Heavy materials like fireclay and alumina make them tough. These bricks usually have a bulk density of 2.0 g/cm³ or more. Their solid build lets them hold heavy things and resist flames.

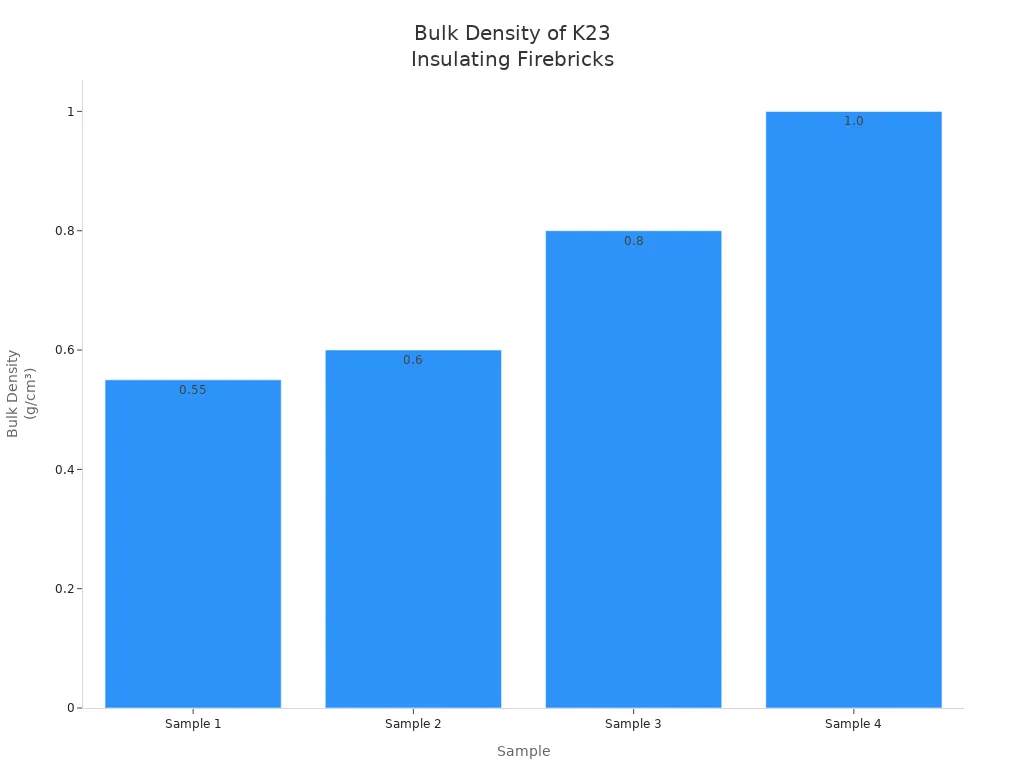

Insulating fire bricks are much lighter. They are also called lightweight refractory bricks. Tests show K23 insulating firebricks have densities from 0.55 to 1.0 g/cm³. This makes them easy to move and lowers the weight on kilns. The table below shows the density of different brick types:

| Brick Type | Bulk Density Range (g/cm³) | Notes |

|---|---|---|

| Insulating Firebricks | 0.55 to 1.5 | Includes various grades; lightweight and low thermal conductivity; designed for insulation |

| Typical Firebricks | ~2.0 or higher | Denser and heavier than insulating firebricks |

Insulating fire bricks are not good for walls that hold weight. They work best as insulation in hot places. Their light weight makes them quick and easy to install, especially in big kilns.

Note: Lower density in insulating bricks means better insulation and easier handling.

Thermal conductivity tells us how fast heat moves through a material. Fire bricks let heat pass through faster than insulating fire bricks. This means fire bricks do not keep heat in as well. Fire bricks are used where strength and flame contact are needed.

Insulating fire bricks have very low thermal conductivity. Their many pores trap air and slow down heat. Mullite insulating firebrick has thermal conductivity between 0.15 and 0.53 W/m·K at 400°C to 600°C. CCEFIRE DJM28 insulating fire brick has 0.34 W/m·K at 600°C and 0.347 W/m·K at 1000°C. These numbers are much lower than dense bricks.

| Material | Density (kg/m³) | Temperature (°C) | Thermal Conductivity (W/m·K) |

|---|---|---|---|

| Mullite insulating firebrick | varies | 400 - 600 | 0.15 - 0.53 |

| CCEFIRE DJM28 insulating firebrick | 0.9 | 600 | 0.34 |

| CCEFIRE DJM28 insulating firebrick | 0.9 | 1000 | 0.347 |

Insulating fire bricks help save energy in furnaces. Studies show kilns with cast insulating fire bricks use up to 38.5% less energy than those with extruded bricks. Insulation bricks can cut heat loss by up to 30% in factories. This saves fuel and helps bricks last longer. It also keeps the outside of furnaces cooler and safer.

Tip: Using insulating bricks with low thermal conductivity can save fuel and make machines more efficient.

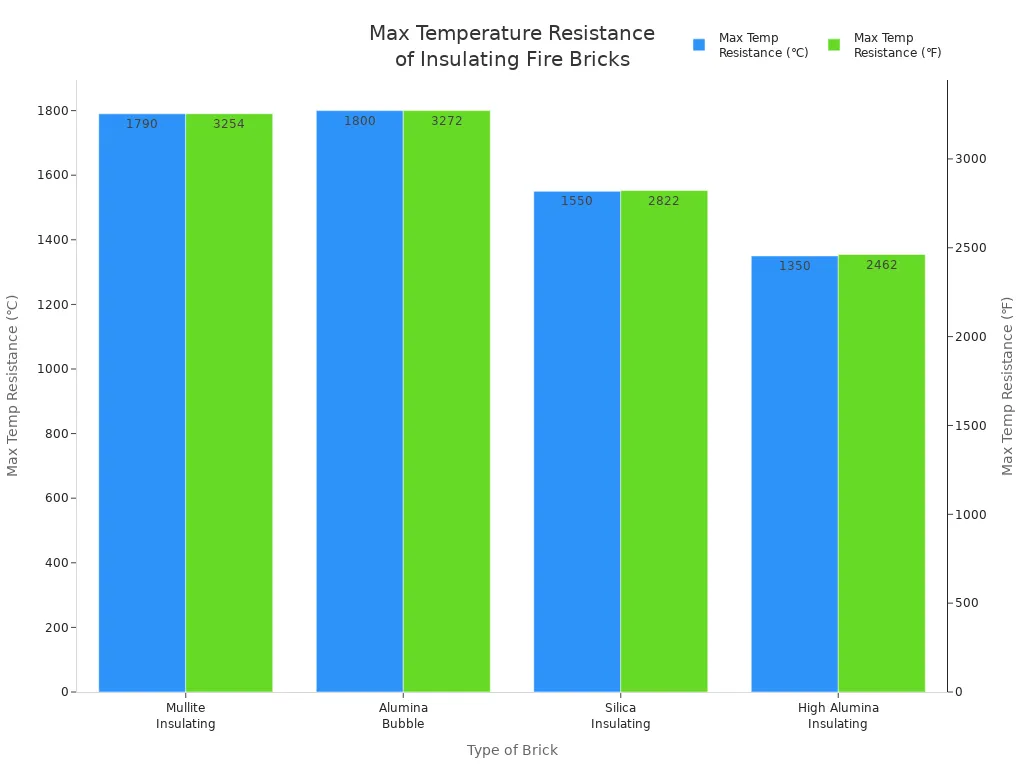

Temperature resistance is important for bricks used in hot places. Fire bricks can handle temperatures over 1500°C. Their dense build and high alumina content make them good for direct flames and heavy jobs.

Insulating fire bricks also resist high heat. Mullite insulating fire brick can take heat above 1790°C (3254°F). Alumina bubble brick can go up to 1800°C (3272°F). Silica insulating fire brick can handle about 1550°C (2822°F). High alumina insulating fire brick can take up to 1350°C (2462°F). Anorthite insulating fire brick works between 1260°C and 1300°C.

| Type of Brick | Composition / Features | Maximum Temperature Resistance (℃) | Maximum Temperature Resistance (℉) |

|---|---|---|---|

| Mullite Insulating Fire Brick | Mullite and bauxite, 42%-72% Al2O3 | Above 1790 | 3254 |

| Alumina Bubble Brick | Alumina hollow spheres and alumina powder | Up to 1800 | 3272 |

| Silica Insulating Fire Brick | >94% silica content | About 1550 | 2822 |

| High Alumina Insulating Fire Brick | >48% Al2O3, alumina bauxite and clay | Not higher than 1350 | 2462 |

Insulating fire bricks keep their shape after many heating and cooling cycles. They do not crack easily from sudden heat changes. This makes them good for kilns, reactors, and furnaces.

Insulating fire bricks give great insulation with low thermal conductivity.

They can handle high heat from 1260°C to 1650°C and survive many heating cycles.

Using them keeps outside surfaces cooler and helps furnaces last longer.

Weight matters for installing and using refractory bricks. Fire bricks are heavy. A regular clay fire brick weighs about 7.5 to 8.4 lbs (3.4 to 3.8 kg). High alumina fire bricks weigh about 8.6 lbs (3.9 kg). Their weight helps them hold heavy loads and resist stress.

Insulating fire bricks are much lighter. A standard K-30 insulating firebrick of the same size weighs only 3 lbs. Some small lightweight insulating bricks weigh just 5 oz (0.31 lbs). Their low weight makes them easy to cut and install. This saves time and money during building.

| Brick Type | Nominal Size (inches) | Weight (lbs) | Density (lbs/cu ft) |

|---|---|---|---|

| Standard Firebrick (hard) | ~9 x 4.5 x 2.5 | Just under 4 | N/A |

| Insulating Firebrick (K-30) | 9 x 4.5 x 2.5 | 3 | 51 |

| Lightweight Insulating Brick | 6 x 3 x 1.5 | 0.31 (5 oz) | 20 |

Insulating fire bricks are light, so they are easy to install and do not add much weight.

Lower density means kilns heat up and cool down faster.

Insulating bricks are not good for walls that must hold heavy loads.

Builders must remember that lightweight bricks are not very strong.

Note: Lightweight refractory bricks are best for insulation layers, not for main walls or heavy structures.

Insulating fire bricks are great for high-temperature insulation. Their low density, low thermal conductivity, high heat resistance, and light weight make them different from dense bricks. Insulation bricks help save energy, keep people safe, and make building easier in many places.

Fire bricks are important in hot places. Factories use them in furnaces and kilns. They also go inside forges. Fire bricks line equipment that gets very hot. These bricks touch flames and need to be strong. Fire bricks help store and move heat well. They must not crack when heated and cooled many times.

People use fire bricks in fireplaces at home. They are also used in pizza ovens. Fire bricks are dense and do not break from high heat. Regular bricks cannot handle this heat. Fire bricks keep ovens and fireplaces safe for years. Installers use special mortar to seal the bricks tightly.

| Firebrick Type | Chemical Composition | Common Industrial Applications | Key Performance Criteria |

|---|---|---|---|

| Alumina Bricks | Clay, high alumina, mullite | High temperature furnaces | Chemical resistance, heat resistance |

| Magnesia Bricks | Magnesia, magnesia calcium | Cement kilns, alkaline environments | Alkali resistance, durability |

| Silica Bricks | Silica, alumina silica | Glass industry, non-ferrous metal kilns | Acid resistance, thermal stability |

Fire bricks last long, keep heat, and make places safe.

Insulating fire bricks are used for insulation in hot machines. Their light and hole-filled build is good for lining kilns and furnaces. Pottery, glass, and metal factories use these bricks to save energy. Insulating bricks keep the outside of machines cool. They also protect other bricks from heat damage.

Insulating fire bricks are found in pizza ovens and outdoor fireplaces. They help keep heat in and save fuel. These bricks slow down heat moving through them. This means ovens heat up faster and use less fuel. Workers can cut and shape these bricks easily. Their low weight makes walls thinner and lighter.

Insulating fire bricks trap air in their holes to insulate better.

They protect other layers and metal shells from heat.

Using them helps save energy and lowers pollution.

Insulating bricks are not good for heavy loads. But they are great for keeping heat in. Their special features make them important for saving energy and controlling temperature.

Picking the right brick for heat retention is important. The type of material matters a lot. Aluminous fire bricks can take heat over 1,700 °C. This makes them good for very hot places. Insulation bricks have lots of tiny holes. These holes trap air and stop heat from escaping. This keeps kilns and fireboxes hot for longer.

Insulation bricks are better at keeping heat in. The air inside slows down heat loss and keeps things hotter.

Firebricks are heavier and hold heat on their surface. But they let heat move through faster, so heat leaves quicker when the fire goes out.

Dense firebricks lose less heat and last longer.

Thicker bricks keep heat in better and do not wear out fast.

Some bricks have special stuff like zirconia or silica carbide. These help the bricks handle quick changes in heat and last longer.

Putting bricks in the right way helps spread heat and stops them from wearing out too soon.

Tip: Use insulation bricks if you want to save energy and keep heat for a long time. Firebricks are best where there are strong flames and heavy use.

Insulation bricks help keep the firebox hot for a long time. Stoves with heavy firebricks warm up slowly but stay warm after the fire is out. Insulation bricks heat up fast but may not last as long. Firebricks with more alumina reflect heat back into the firebox.

Energy efficiency is important for homes and factories. Insulation bricks help stop heat from escaping. This saves energy and lowers costs. These bricks are made to last and work well.

Insulation bricks keep more heat inside than firebricks. This helps the firebox stay hot.

Keeping heat in helps the fire burn better and longer with less air.

People say that using insulation bricks lets them use less air and still get good heat. This means more heat at lower settings.

Some stove makers use insulation bricks to make stoves work better.

In kilns, insulation bricks stop heat from escaping because they do not let heat pass through easily. Cast insulation bricks save the most energy.

Tests show that kilns with cast insulation bricks use up to 38.5% less energy than kilns with other bricks.

Models show that cast insulation bricks need less energy to stay hot. This saves a lot of fuel money.

Even though cast insulation bricks cost more at first, they save money over time.

Kilns with insulation bricks stay cooler on the outside, making work safer and more comfortable.

Note: Insulation bricks help use less energy, save fuel, and make kilns last longer. They also make products better and keep workers safe.

Many factories use insulation bricks, like those making metal, chemicals, ceramics, aluminum, and glass. These bricks help machines work better and save money. Using insulation bricks in kilns helps save money and makes kilns work longer.

Bricks need to be strong in hot places. Firebricks and insulation bricks are different in strength and weight.

| Property | Insulation Bricks | Firebricks |

|---|---|---|

| Density | Low (0.8–1.0 g/cm³), lightweight | High (>2.0 g/cm³), dense |

| Workability | Easy to cut and install | Requires specialized cutting tools |

| Mechanical Strength | Lower, less durable | High, suitable for direct flame and abrasion |

| Installation | Simpler and faster | More complex, needs careful handling |

| Maintenance | May require more frequent replacement | Less frequent replacement, more durable |

Diatomite insulation bricks are very light. Their many holes make them good for keeping heat in but not for holding weight. Lightweight refractory bricks are strong and last long, so they are better for support in hot factories.

Dense firebricks are very strong and can take a lot of heat. They are good for holding up heavy things in furnaces, kilns, and forges. Insulation bricks are great for keeping heat in but are not as strong or heavy. This means they are not the best for holding up weight.

Firebricks are heavy and have fewer holes, so they are stronger. Insulation bricks, also called soft fire bricks, have more holes and are lighter, so they are not as strong. Firebricks are better for holding up weight. Insulation bricks are made to keep heat in, not to be strong.

Safety Tip: Always check how strong and heavy bricks are before using them to hold up weight. Dense firebricks are best for staying strong under heat and pressure.

How you put in and take care of bricks is different. Firebricks need special tools and careful work. Insulation bricks are lighter and easy to cut, so they are faster to put in. But insulation bricks may need to be replaced more often because they do not last as long.

Making firebricks can pollute the air and make waste. Throwing them away can be hard if they are dirty. Using clean energy and recycling helps the planet.

Experts say to pick firebricks based on what they are made of, how much heat they can take, and what you need them for. For the most heat and strength, use silica bricks, high-alumina refractories, or chromite refractories in forges. Insulation bricks made from alumina and silica can take up to 2300°F and are good for ovens, kilns, fireplaces, and glass furnaces.

Maintenance Tip: Fill in cracks, clean often, keep bricks dry, and get help from pros if needed. Always work in fresh air and wear a mask to stay safe from fumes.

Firebricks and insulating bricks are used for different jobs in hot places. Firebricks are strong and can handle direct flames. Insulating bricks are good at keeping heat in and saving energy. When picking a brick, remember these tips:

Make sure the brick can take high heat and does not let heat pass through fast.

Check if the brick is strong against chemicals and pressure.

Pick the right size and shape for what you need.

Buy bricks from companies you can trust.

Choosing the right brick keeps things safe, saves energy, and helps your project last a long time.

Insulating bricks use special clays, alumina, and silica. Makers mix in things like sawdust or polystyrene. These burn away when fired. This leaves tiny air pockets inside. The brick is light and full of holes. It traps heat and helps save energy.

Insulating bricks do not do well with direct flames. They are not very strong and can break under heavy loads or hot flames. Firebricks are better for places with direct flame.

People put insulating bricks inside kilns. These bricks help keep heat in and lower energy loss. They work best behind firebricks, not as the main wall.

Insulating bricks have lots of air pockets. These slow down heat moving through. This keeps kilns and furnaces hot longer. Using them helps factories save fuel and money.

Yes, insulating bricks are light and soft. Workers can cut them with simple tools. This makes putting them in faster and easier than firebricks.