Views: 0 Author: Site Editor Publish Time: 2025-08-09 Origin: Site

Refractory bricks are also called fire bricks. They are special building materials. They can handle very high heat. They do not melt or change shape. Regular bricks cannot do this. Refractory bricks use pure materials like alumina and silicon carbide. This makes them strong and able to resist heat. These bricks protect buildings from damage. They work well in places with lots of heat, like furnaces or kilns. Factories and homes use refractory bricks for safety. They help things last longer when there is strong heat.

Refractory bricks can handle very high heat. They help keep buildings safe when normal bricks cannot. These bricks save energy by keeping heat inside furnaces, kilns, and fireplaces. This means people use less fuel. There are different types of refractory bricks for different jobs. Some are used in steelmaking, glass factories, or home fireplaces. Refractory bricks do not get damaged by chemicals or physical force easily. This helps them last longer in hard places. Using refractory bricks makes hot places safer, stronger, and more efficient in homes and factories.

Refractory bricks have special features that help them work in hot places. These features make them different from regular bricks. They keep buildings and machines safe in tough conditions. The next parts talk about what makes refractory bricks work so well.

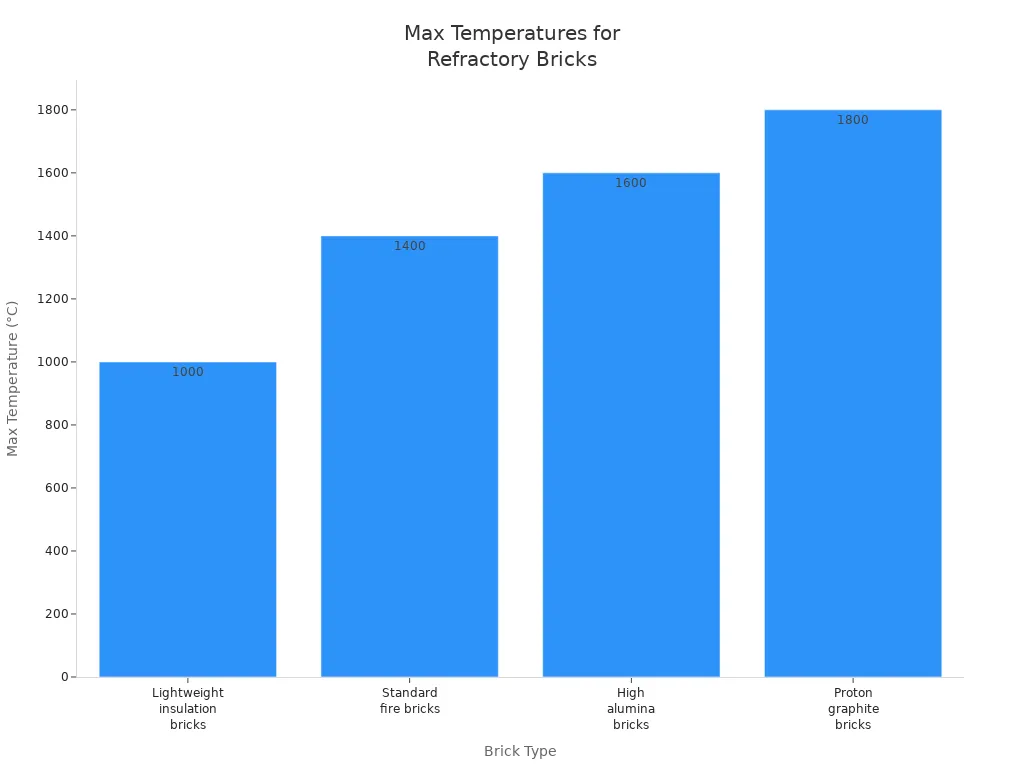

Refractory bricks can handle very high heat. They do not melt or lose their shape. This is why they are used in furnaces and kilns. Each kind of refractory brick can take a different amount of heat. The table below shows how much heat some types can take:

| Type of Refractory Brick | Typical Temperature Range (°C) | Key Characteristics and Usage |

|---|---|---|

| Fireclay bricks | Up to 1700 | Used in secondary kiln sections; load softening temperature ~1300°C |

| High alumina bricks | 1420 - 1550 | Al₂O₃ content affects refractoriness and strength; used in extreme heat zones |

| Mullite bricks | 1260 - 1650 | High refractoriness, thermal shock resistance, used in flue linings |

| Corundum bricks | ~1700 | High alumina content (>90%), suitable for long-term use at high temperatures |

| Clay bricks | ~1400 | Typically used below 1400°C due to strength limitations |

| Lightweight insulation bricks | ~1000 | Used for insulation, not direct flame contact |

Refractory bricks stay strong even at 2100°C. This keeps people and machines safe in factories. Regular bricks would break or melt in these places.

Refractory bricks do not just stand up to heat. They also stop heat from moving through them. This means they are good at keeping heat inside furnaces and kilns. This helps save energy and keeps the outside cooler. The table below shows how well different refractory bricks stop heat:

| Refractory Brick Material | Thermal Conductivity (W/m·K) |

|---|---|

| Silicon Carbide (SiC) | 50 - 120 |

| Fireclay Bricks | 1 - 3 |

| High-Alumina Bricks | 2 - 5 |

| Magnesia-Chrome Bricks | 3 - 8 |

Normal bricks let heat out much faster. This makes them bad for hot places. Refractory bricks have things like ceramics and iron oxide inside. These help soak up heat and stop it from spreading. This makes factories use less energy.

Tip: Using refractory bricks in furnaces and kilns saves energy and keeps people safer by holding in the heat.

Refractory bricks must not get damaged by acids or other chemicals. They have things like silica, alumina, magnesia, and corundum inside. These make the bricks strong and hard for chemicals to get in. This helps the bricks last longer and not break down.

Silica, alumina, magnesia, and corundum help block acids and alkalis.

Flint, clay, and silica make bricks that resist acid.

High alumina, magnesia, corundum, and silica bricks are tough in harsh places.

Acid resistant bricks stay strong against sulfuric acid, hydrochloric acid, and nitric acid.

The table below shows how different refractory bricks fight off damage from chemicals:

| Type of Refractory Brick | Corrosion Resistance Mechanism and Features |

|---|---|

| High Alumina Bricks | Good thermal shock resistance; poor alkali corrosion resistance; volume changes under alkali exposure. |

| Corundum Bricks | Stable volume; good alkali metal resistance; crystal structure absorbs alkali ions. |

| Magnesia-Chrome & Chrome-Corundum | High refractoriness and strength; dense with low porosity; good alkali and slag erosion resistance; chrome offers acid resistance. |

| Calcium Aluminate Series | Stable in high-temperature reducing atmospheres; good alkali corrosion resistance. |

| Magnesia Alumina Spinel | Excellent alkali corrosion resistance; low thermal conductivity; high strength and hardness. |

| Composite Bricks | Good alkali corrosion resistance; thermal shock stability; strong acid resistance. |

| Aluminum-Carbon Series | Slow alkali corrosion rate; prevents embrittlement and damage. |

Refractory bricks form a hard layer that stops acids and alkalis. Their tight structure keeps chemicals out. This helps the bricks last longer and keep things safe in rough places.

Refractory bricks need to be strong. They must hold up heavy things and not break when they get hot or scratched. Their strength keeps kilns and other hot places working right.

| Brick Type | Temperature (°C) | Compressive Strength (MPa) | Notes |

|---|---|---|---|

| Geopolymer-based refractory bricks | 600 | 5.51 | About double commercial refractory bricks |

| Geopolymer-based refractory bricks | 800 | 6.60 | Higher strength at elevated temperature |

| Commercial refractory bricks | N/A | 2.80 | Average compressive strength |

Concrete with refractory brick pieces is strong enough for most jobs. But it is not as strong as special concrete. Refractory bricks are not as strong as regular bricks, but they are strong enough for hot places.

Refractory bricks must handle heat, pressure, and being scratched. Their strength means less time fixing things in factories. Kilns work in hard conditions, and refractory bricks stop cracks and breaks. Adding things like graphitic carbon microspheres can make them even stronger and last longer.

Note: Strong refractory bricks help machines last longer and work better, which saves money on repairs.

Refractory bricks are good at handling heat, stopping heat loss, fighting chemicals, and staying strong. These features make them the best choice for protecting buildings in hot places. They last a long time and save energy, which makes them better than regular bricks for many jobs.

Refractory bricks have different types. Each type uses special materials and has its own job. The table below lists the main types, their examples, and what they are made from:

| Main Type of Refractory Brick | Subtypes / Examples | Primary Raw Materials / Composition |

|---|---|---|

| Acid Refractory Bricks | Silica bricks, Fireclay bricks, Ganister bricks | Silica (SiO₂) ~95%, Mullite, Clay, Lime (CaO) |

| Basic Refractory Bricks | Magnesite bricks, Dolomite bricks, Bauxite bricks | Magnesia (MgO) >85%, Calcium oxide (CaO), Aluminium oxide (Al₂O₃) |

| Neutral Refractory Bricks | Chromite bricks, Chrome magnesite bricks, Spinel bricks, Forsterite bricks | Chrome oxide (Cr₂O₃), Magnesia (MgO), Alumina (Al₂O₃), Forsterite mineral |

Fire brick is the most common refractory brick. It is made with good clay and has alumina between 30% and 48%. Fire bricks can take heat from 1200°C to 1500°C. They do not break from heat or fast temperature changes. People use fire bricks in fireplaces, wood stoves, and pizza ovens. Factories put fire bricks in blast furnaces and hot stoves. Yufeng Refractory makes fire bricks that are strong and keep heat in. Fire bricks are also used in kilns and incinerators. Many people pick fire bricks for homes and factories because they last long and hold heat well.

High alumina brick has more alumina than fire brick. It has alumina from 48% up to 90%. More alumina means it fights heat, chemicals, and pressure better. These bricks can take heat up to 1790°C. Factories use high alumina bricks in steel furnaces, cement kilns, and glass tanks. Yufeng Refractory makes many grades for different jobs. High alumina bricks keep their shape and strength even when things get tough.

Silica brick has at least 93% silica inside. This brick can take heat above 1650°C. Silica bricks stay strong and do not change at high heat. Factories use them in glass furnace tops, coke ovens, and stove domes. Glass and steel companies need silica bricks because they do not wear out fast. The chart below shows how many places use silica bricks:

Silica bricks also do not get damaged by acid, so they are good for petrochemical plants.

Magnesia-carbon brick mixes magnesia and carbon, often graphite. This mix helps the brick fight heat, chemicals, and quick temperature changes. Magnesia-carbon bricks work well in steel furnaces, converters, and ladles. These bricks are strong and do not get ruined by slag or melted metal. Yufeng Refractory makes magnesia-carbon bricks that are dense and have few holes. This helps them last longer and means less fixing in steel plants. Magnesia-carbon bricks help protect machines and save energy in big factories.

Refractory bricks are important in many places. They help protect buildings and machines. They can handle high heat and strong chemicals. They also help save energy. Each kind of refractory brick has its own job. The right brick is picked for each place.

Industrial furnaces get very hot. They also touch strong chemicals. Refractory bricks line the inside walls. This keeps the furnace safe and holds in heat. Many factories use these bricks. Steel, cement, glass, ceramics, metal smelting, petrochemical, and waste plants need them.

Common uses in industrial furnaces:

Lining blast furnaces, electric arc furnaces, ladles, and rotary kilns.

Giving insulation to stop heat from escaping.

Blocking damage from slag and melted metal.

Helping save energy and lower costs.

Different bricks are used for different jobs:

Alumina-based bricks work well in steel and glass furnaces. They resist acid slag and have high melting points.

Magnesia bricks are good for cement and steel factories. They fight alkaline slag.

Clay bricks are used in blast furnaces, hot stoves, and glass kilns.

Corundum bricks keep heat in and last a long time.

Picking the right refractory bricks keeps furnaces safe. It also saves energy and stops heat from leaking out.

How refractory bricks help save energy:

Light bricks make heat loss less and repairs easier. Tunnel kiln car linings can save up to 70% energy.

Insulation wool like ALTRA® 1500C lasts longer. It works well in furnaces that heat and cool quickly.

Mixing bricks with light materials and wool gives strength and good insulation.

Smart lining design helps save energy and money.

Corundum bricks do not let much heat pass through. This keeps heat inside and saves fuel. Thin linings and quick heating are possible. Strong bricks mean less fixing and less energy used when starting or cooling down.

Steelmaking needs bricks that can take lots of heat. They also must fight strong slags. Refractory bricks keep furnaces safe and steady. Magnesia bricks are made from magnesium oxide. They resist basic slags and work above 1800°C. They also let heat move well and handle shocks.

Silica bricks have lots of silicon dioxide. They work up to 1700°C and fight acid slags. These bricks are used in coke ovens and acid converters. Insulating fire bricks are light and do not let much heat out. This helps steel furnaces save energy.

| Furnace Type | Preferred Refractory Type | Role/Properties |

|---|---|---|

| Blast Furnaces | Carbon and High-Alumina | Handle molten iron and slag; protect furnace structure from extreme heat and corrosive materials. |

| Basic Oxygen Furnaces | Magnesia-Carbon Bricks | Resist basic slag corrosion and thermal shock; maintain furnace integrity during steel refining. |

| Steel Ladles | Magnesia-Based Bricks | Provide corrosion resistance and safety in handling molten steel. |

| Tundishes | Alumina-Based Monolithics | Ensure smooth molten steel transfer during continuous casting. |

Magnesia bricks need to be kept dry. Water can hurt them. Good storage keeps them working well. In steelmaking, refractory bricks protect furnaces and save energy. They also keep things running smoothly and safely. Strong bricks mean less fixing and less stopping work.

Kilns and fireplaces get very hot. They also face corrosion and scratches. Refractory bricks like fire bricks, high alumina bricks, silica bricks, magnesia bricks, insulating fire bricks, and special bricks help fight these problems.

Insulating fire bricks make kilns safer and stronger. They keep heat in and stop heat from escaping. Their light weight and low heat passing help kilns last longer. Refractory mortar holds bricks together and stands up to heat. This makes kilns and fireplaces strong and safe.

Heavy bricks in wood kilns hold lots of heat. They are strong and fight scratches and chemicals. These bricks keep heat in and protect the kiln. Light bricks are more porous and give better insulation. They also fight heat shock and protect kiln parts. These features help kilns last longer and need less fixing.

Fire bricks and other refractory bricks keep kilns and fireplaces safe. They hold heat, fight damage, and help the structure last.

Chimneys and insulation need bricks that can take lots of heat. They also face strong chemicals. Refractory bricks stay strong at high temperatures. They also block damage from gases and particles.

Benefits of refractory bricks in chimneys and insulation:

High thermal stability keeps chimneys safe at high temperatures.

Chemical resistance protects against corrosion in industrial and heating applications.

Durability and long lifespan reduce maintenance and replacement needs.

Excellent insulation properties minimize heat loss and improve energy efficiency in heating systems.

Insulating firebrick withstands temperatures up to 3,200°F while conducting very little heat, which boosts energy efficiency.

High insulating value allows for thinner walls and lower operating costs.

High compressive strength supports self-sustaining structures at elevated temperatures.

Low heat storage leads to reduced fuel consumption and faster heat-up times.

High purity reduces impurities that could harm performance, ensuring longevity and reliability.

Precise dimensions enable tight, strong refractory linings that minimize heat loss through joints.

Refractory bricks help chimneys and insulation keep heat inside. They also block chemicals and support the structure. Their insulation saves energy and lowers fuel costs. Fire bricks and insulating fire bricks are used because they are strong and save energy.

Refractory bricks act as shields and energy savers in chimneys and insulation. They make heating safer and more efficient.

Summary of Uses:

Industrial furnaces use refractory bricks to protect, save energy, and fight chemicals.

Steelmaking uses magnesia, silica, and alumina bricks for safety and strength.

Kilns and fireplaces use fire bricks and insulating bricks to hold heat and last longer.

Chimneys and insulation use refractory bricks for heat stability, chemical resistance, and energy savings.

Refractory bricks are needed in hot places. Their special features protect equipment, save energy, and keep people safe in factories and homes.

Fire brick helps keep hot places safe. It has special features that stop accidents. These features protect people and machines. The table below explains how each feature helps with safety:

| Property | Description | Safety Contribution |

|---|---|---|

| Chemical Resistance | Low porosity and high density block liquids and gases; alumina layer shields against corrosion | Stops chemical damage and corrosion, keeping structures strong in harsh conditions |

| Thermal Shock Resistance | Small, connected holes spread out stress; low thermal conductivity slows heat transfer | Prevents cracks or breaks during quick temperature changes, making the area safer |

| High-Temperature Resistance | Made from materials with high melting points like alumina and silica | Keeps its shape and strength under extreme heat, reducing the risk of failure |

| Mechanical Strength | Tightly packed particles boost strength and wear resistance | Handles heavy loads and stress without breaking |

| Reversible Volume Expansion | Expands with heat but returns to normal size after cooling | Avoids leaks and cracks, keeping insulation and containment secure |

Fire brick stays strong even when things get tough. It does not break or lose shape easily. This makes it a good choice for furnaces, kilns, and fireplaces.

Fire brick lasts many years in homes and factories. How long it lasts depends on how it is used and cared for. The table below shows how long fire brick can last and what can change that:

| Application Type | Average Lifespan | Key Influencing Factors |

|---|---|---|

| Residential (Domestic) | 15 to 25 years | Good installation, regular care, avoiding thermal shock |

| Industrial | 5 to 10 years | Intense heat, chemical exposure, fuel type, maintenance |

At home, fire brick can last up to 25 years. This is because homes are not as harsh as factories. In factories, fire brick faces more heat and chemicals. This means it might need to be replaced sooner. Checking and caring for fire brick helps it last longer anywhere.

Fire brick helps save energy in hot places. It does not let heat escape fast. This keeps the inside hot and the outside cooler. Fire brick can also soak up and hold heat well. This helps keep the temperature steady and saves energy.

Some new fire bricks can store heat longer and even help heat things up. These bricks help factories use less fuel and work better. Because fire brick is strong and fights chemicals, it does not need to be replaced often. This saves energy and money too.

Tip: Fire brick makes heating safer and saves energy. It is a smart pick for homes and factories.

Refractory bricks help protect buildings from very high heat. They keep people and machines safer than regular bricks. They last longer and save more energy. The table below shows how they are better:

| Aspect | Refractory Bricks | Regular Bricks |

|---|---|---|

| Heat Resistance | Up to 2700°F or more | Degrade around 1200°F |

| Durability | Resist corrosion and abrasion | Prone to weathering and erosion |

| Safety | Safer for high-heat environments | Not suitable for extreme heat |

Factories and homes use refractory bricks because they work well. They last a long time and help save energy. This makes them a smart choice for many jobs.

A Refractory Brick is made to handle very high heat. People use it in furnaces, kilns, and fireplaces. It keeps buildings safe from heat and damage.

A Refractory Brick stands up to heat, chemicals, and pressure. Regular bricks can break or melt when it gets hot. Refractory Bricks last longer and keep heat inside. This makes them safer for jobs with high temperatures.

People use Refractory Bricks in steel plants and glass factories. They also go in pizza ovens, fireplaces, and chimneys. These bricks protect places from strong heat and chemicals.

A Refractory Brick can last 15 to 25 years in homes. In factories, it lasts 5 to 10 years. Good care and installation help it last longer.

Yes! Refractory Bricks hold heat and stop it from escaping. This helps furnaces and kilns use less fuel. Saving energy lowers costs and helps machines work better.