Views: 17 Author: Site Editor Publish Time: 2025-08-03 Origin: Site

In many industries, bad insulation causes energy loss up to 8.3%. This happens a lot in places with high heat. Insulating bricks, like clay-based ones, can help stop this loss. These bricks have many good points:

They are light, so they are easy to move and put in.

They help save energy, so you need less heating and cooling.

Clay-based insulating bricks use things like fibers and waste. This helps them insulate better and be more eco-friendly.

Fire bricks and insulating bricks both help protect equipment. But insulating bricks keep heat in better.

Insulating bricks are light. They have many tiny holes. These holes trap air. This helps keep heat inside. It also saves energy.

These bricks work well in hot places. You can use them in factories and homes. They help reduce heat loss. They protect machines from heat.

Fire bricks are very strong. They can handle direct flames. Insulating bricks are better for keeping heat in. People put them behind fire bricks.

Picking the right brick is important. You need to check heat resistance. You should look at strength and cost. Getting expert advice helps you choose the best brick.

Good installation is important. Tight joints and good mortar help a lot. This makes insulating bricks last longer. It also helps save more energy.

Insulating bricks are made to keep heat in or out. They work well where heat control is important. People also call them insulating fire bricks or insulating firebrick. They are made from things like alumina, silica, and clay. Makers sometimes add grog or other minerals. This makes the bricks stronger and better at handling heat. Insulating bricks are not the same as regular fire bricks. They are made to stop heat from moving, not just to handle high heat.

| Aspect | Insulating Fire Bricks (Firebricks) | Traditional Fire Bricks (Common Bricks) |

|---|---|---|

| Raw Materials | Alumina, silica, magnesia, refractory minerals, sometimes grog | Natural clay, shale, sometimes sand |

| Additives | Grog to improve thermal shock resistance | Lime or fly ash to improve strength |

| Firing Temperature | Very high, often over 1400°C | Lower, generally 900°C–1100°C |

| Texture | Dense or porous depending on application; low iron content | More porous; higher iron content (reddish color) |

| Heat Resistance | Can withstand 1200°C–1800°C without losing strength | Generally up to 600°C–800°C |

| Thermal Conductivity | Low, good insulators | Higher, lose heat faster |

| Mechanical Strength | High compressive strength (up to 60 MPa or more) | Moderate strength (20–40 MPa), loses strength at high heat |

| Thermal Shock | Resistant to thermal shock | More likely to crack under rapid temperature changes |

People use insulation bricks in kilns and furnaces. They are also used in other hot places. These bricks help keep heat inside. This saves energy and makes them a good choice for many projects.

Insulating bricks have special features that help with insulation. They are light and have lots of tiny holes. These holes trap air inside the brick. Air helps stop heat from moving through the brick. This makes the bricks good at slowing down heat.

Note: Insulation bricks have many pores. This lowers their bulk density and lets them trap more air. That is why they are great for insulation.

Insulation bricks usually have thermal conductivity between 0.2 and 0.4 W/m·K. This is much lower than dense fire bricks. Dense fire bricks are heavier and let heat move faster. Insulating lightweight refractory bricks are easy to carry and put in place. New ways to make these bricks use things like sawdust or rice husk ash. This adds more holes and makes the bricks even better at insulation. These new bricks are also better for the environment.

Insulation bricks can handle quick changes in temperature. They do not crack easily when it gets hot or cold fast. Their makeup and design make them a good pick for both factories and homes.

Insulating firebrick is very good at keeping heat in. These bricks have lots of tiny holes inside them. The holes trap air and slow down heat. Because of this, insulation bricks do not let heat move fast. They have lower thermal conductivity than regular fire bricks. ASTM standards say the many pores help stop heat loss. They also keep the outside of equipment cooler. This means less heat gets out of furnaces or kilns. It helps save energy and makes work safer.

A Stanford University study found that using these bricks saves energy and money. The bricks hold heat well, so equipment needs less energy to stay hot. The study showed that firebricks can lower costs for batteries and hydrogen. Insulation bricks also keep the outside of machines cooler. This protects workers and saves more energy. The bricks are light, so they are easy to put in and take out. This makes them a smart choice for saving energy.

Insulation bricks help a lot in places with high heat. They protect machines and help them work better. Here are some main benefits:

Insulating fire bricks can handle heat up to 1800°C. This makes them good for very hot jobs.

They protect machines from quick changes in heat, rust, and heavy weight. This helps machines last longer.

Their low thermal conductivity keeps heat from escaping. This saves energy.

You can get bricks in many shapes and sizes for different machines.

Strong bricks last a long time and need less fixing.

Industries like ceramics, petrochemicals, aluminum, glass, and steel use these bricks. The bricks are light and can take a lot of heat. They help lower costs and are better for the environment. In chemical plants, they line hot machines to keep heat in and stop damage from chemicals. In power plants, they line boilers and furnaces to keep things safe and working well. Insulating bricks are important for saving energy and helping industries meet new rules.

Fire bricks and insulating bricks are made from different materials. Fire bricks are heavy and strong. Their density is more than 2.0 g/cm³. They have a tight structure. This makes them tough and good at handling fire. Fire bricks can stand very high heat, over 1400°C. Some can even work at 1760°C. Because they are dense, heat moves through them fast. Their thermal conductivity is above 1.0 W/m·K.

Insulating bricks are much lighter. Their density is between 0.8 and 1.0 g/cm³. They have lots of tiny holes filled with air. This helps them keep heat from moving. The air inside slows down heat transfer. Their thermal conductivity is much lower, from 0.2 to 0.4 W/m·K. Insulating bricks can handle heat up to 1400°C. They are not made for direct flames. Their main job is to stop heat from escaping.

Note: Fire bricks are built for strength and fire resistance. Insulating bricks are made to be light and keep heat in.

The table below shows how they are different:

| Property | Fire Bricks | Insulating Bricks |

|---|---|---|

| Density | Above 2.0 g/cm³ (dense) | 0.8–1.0 g/cm³ (lightweight) |

| Thermal Conductivity | >1.0 W/m·K (high) | 0.2–0.4 W/m·K (low) |

| Refractoriness | Above 1400°C | Below 1400°C |

| Mechanical Strength | High (durable, abrasion resistant) | Low (less durable) |

| Structure | Compact, few pores | Porous, many air pockets |

| Fire Resistance | Excellent | Good, but not as high as fire bricks |

Fire bricks use tough materials like alumina and silica. These help them stand up to high heat and fire. Insulating bricks use similar stuff but add light fillers or make more holes. This makes them better at keeping heat in but not as strong.

Fire bricks and insulating bricks do different jobs. Fire bricks are used where there is direct flame or very high heat. They line the inside of furnaces and kilns. Their tight structure helps them resist fire and heat. They do not break easily when things get hot or when chemicals touch them. Many steel and glass factories use fire bricks in the hottest spots.

Insulating bricks are not as tough. Their main job is to keep heat inside. They are often placed behind fire bricks in walls. Fire bricks face the flame, and insulating bricks stop heat from getting out. Insulating bricks help save energy by keeping heat in. They also keep the outside cooler, which protects workers.

Tip: Many kilns use both types of bricks. Fire bricks face the flame, and insulation bricks sit behind to keep heat in.

Here is a table that compares their uses:

| Property | Insulating Bricks | Fire Bricks |

|---|---|---|

| Thermal Conductivity | Low (0.2–0.4 W/m·K) | High (>1.0 W/m·K) |

| Maximum Service Temp | Up to 1400°C | Above 1400°C |

| Density | Low (0.8–1.0 g/cm³) | High (>2.0 g/cm³) |

| Mechanical Strength | Low | High |

| Durability | Less durable, lower mechanical strength | Superior durability, abrasion and chemical resistance |

| Workability | Easy to cut and install | Requires specialized tools |

| Cost | Generally lower | Generally higher |

| Fire Resistance | Good | Excellent |

Fire bricks are very strong. They resist fire and high heat well. Their tight structure makes them last a long time. They can take direct flame, heavy loads, and harsh chemicals. Fire bricks do not insulate well. Heat escapes quickly, which can cost more energy.

Insulating bricks are light and easy to put in. They keep heat inside, which saves energy. They also keep surfaces cooler. Their weakness is that they are not very strong. They cannot take direct flame or heavy loads as well. Their fire resistance is good but not as high as fire bricks. They may wear out faster in tough places.

Summary: Fire bricks are best for direct flame and tough jobs. Insulating bricks are best for keeping heat in and saving energy.

Fire bricks: Furnace linings, kiln walls, reactor chambers, places with direct flame or heavy use.

Insulating bricks: Back-up insulation in kilns and furnaces, outer layers of hot equipment, places where weight matters.

Many industries use both types together. This gives the best fire resistance, heat protection, and insulation. It also helps machines last longer and saves energy.

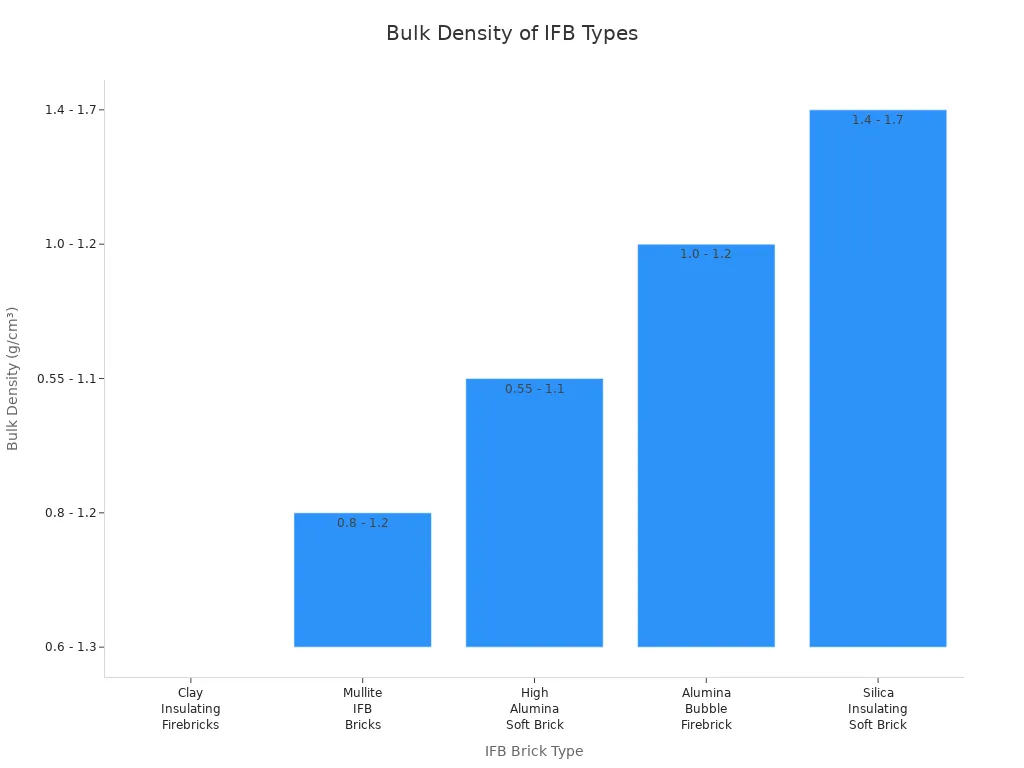

Many factories use insulating fire bricks to save energy. These bricks help protect machines from heat. You can find them in glass kilns and ceramic furnaces. They are also in steel ladles, aluminum smelters, and power plant boilers. The bricks are light and have many tiny holes. This makes them easy to put in place. The holes help stop heat from escaping. The table below lists different brick types and their features:

| Type of IFB Brick | Temperature Range (°C) | Alumina Content (%) | Bulk Density (g/cm³) | Cold Crushing Strength (MPa) | Thermal Conductivity (W/m·K) |

|---|---|---|---|---|---|

| Clay Insulating Firebricks | Up to 1800 | 30-48 | 0.6 - 1.3 | ≤1.3 - 5 | 0.25 - 0.55 |

| Mullite IFB Bricks | Up to 1800 | ≥48 | 0.8 - 1.2 | 2.5 - 4.5 | ≤0.35 - 0.55 |

| High Alumina Soft Brick | Up to 1800 | 38 - 73 | 0.55 - 1.1 | 0.17 - 0.43 | 0.17 - 1.5 |

| Alumina Bubble Firebrick | Up to 1800 | 90 - 99 | 1.0 - 1.2 | 2.0 - 5 | ≤0.8 - 1.5 |

| Silica Insulating Soft Brick | Up to 1800 | ≥91 | 1.4 - 1.7 | 9 - 12 | 0.55 - 0.70 |

Factories need bricks that can take high heat and block chemicals. These bricks also need to keep heat inside. Workers often put these bricks behind dense fire bricks. This helps keep furnaces and kilns hot. It saves energy and keeps the outside safe.

Tip: Pick the right brick for the heat and chemicals in your machine. This helps the bricks work best.

People use insulating fire bricks at home too. They are in pizza ovens, fireplaces, wood stoves, and backyard kilns. These bricks keep heat inside ovens and stoves. This makes food cook faster and saves fuel. The bricks are light and soft. You can cut them to fit any shape you need.

| Property | Description |

|---|---|

| Low Thermal Conductivity | Stops heat from escaping, saves energy. |

| High Heat Resistance | Handles up to 2500°F, great for ovens and fireplaces. |

| Lightweight | Simple to move and put in place. |

| Easy to Cut and Shape | You can make them fit your project. |

| Accurate Dimension | Fits tightly, so less heat gets out through cracks. |

| Wide Application | Works in ovens, stoves, fireplaces, and other heaters. |

Note: Use the right tools and wear safety gear when working with bricks. Always follow the maker’s instructions. Dry fit the bricks before using mortar. Make sure the bricks fit tight to stop heat leaks.

If you install the bricks the right way, they last longer. They also work better. In factories and homes, these bricks help save energy. They protect machines and make heating safer and more efficient.

Picking the best insulating brick takes some planning. Experts say you should follow clear steps to choose the right brick for your project. Here are some things to do:

Talk to the makers about what your project needs. They can help you pick the right brick.

Find out what firing temperature you need. Most bricks work well from 1200°C to 1400°C. If you need higher heat, you may need special bricks.

Ask if the glaze is good. Good glaze helps the brick last longer and work better.

Look at all the costs, like buying, shipping, and putting in the bricks.

Check if the bricks are strong and tough. Jobs with high heat need bricks that can take heat and hits.

The table below lists important things to check:

| Factor | Why It Matters |

|---|---|

| Thermal Conductivity | Lower numbers mean better insulation and save energy. |

| Fire Resistance | High fire ratings keep people and equipment safe. |

| Moisture Resistance | Needed in wet places to stop damage. |

| Compressive Strength | Needed for heavy things or places that get hit a lot. |

| Environmental Impact | Eco-friendly bricks help save energy and cut down on waste. |

| Installation Method | The right way to lay bricks and use mortar makes them last longer. |

| Cost | Think about both the first price and how much you save later. |

| Application Needs | Make sure the brick fits the heat and weight your project needs. |

Putting in the bricks the right way helps them work better. Here are some tips:

Place bricks close together so heat does not leak out.

Use good refractory mortar to make strong joints.

Lay bricks in a staggered way to make the wall stronger.

Do not let metal touch hot bricks. Use insulation boards to keep them apart.

Seal the joints well to keep water out.

Cut bricks carefully to fit corners and round spots.

Let the mortar dry all the way before heating up the bricks.

Check for cracks or damage often and fix them fast.

Tip: Always get trained workers to put in the bricks. Handle and store bricks with care before using them so they do not break.

Insulating fire bricks need less fixing than regular clay bricks. Their design helps stop cracks and damage from quick changes in heat. Checking and fixing them often helps them last longer and keep heat in.

Insulating bricks help keep heat in and save energy. They also make buildings more eco-friendly. Fire bricks are very strong and can handle direct flames. This makes them good for places with a lot of heat. People in the industry should pick bricks based on how hot it gets, how strong they need to be, and how well they keep heat in.

Experts say you should talk to specialists and use exact information to pick the best bricks for each job.

| Benefit | Limitation |

|---|---|

| Energy efficiency | Higher cost for advanced types |

| Lightweight structure | Price volatility in raw materials |

Insulating bricks are light and have many tiny holes. These holes trap air inside the brick. The trapped air helps slow down heat movement. Regular bricks are heavy and packed tight. Heat moves through regular bricks much faster. Insulating bricks help save energy in hot places.

People use insulating bricks in pizza ovens and fireplaces. They also use them in wood stoves at home. These bricks help keep heat inside ovens and stoves. This makes cooking and heating work better. The bricks are light and easy to put in. You can cut them to fit special shapes.

Insulating bricks help stop heat from escaping in kilns and furnaces. They also keep reactors hot for a long time. This means machines use less fuel to stay hot. The bricks keep the outside cooler, so workers are safer. Many factories use these bricks to save more energy.

Insulating bricks can take high heat but not direct flame. They are not good for heavy loads either. Factories put fire bricks in front to face the flame. Insulating bricks go behind to help keep heat in.

Buyers need to check how well the bricks stop heat. They should also check fire resistance and strength. The bricks must match the heat and chemicals in the project. Experts say to ask the makers for help picking the best bricks.