Views: 1 Author: Site Editor Publish Time: 2025-08-01 Origin: Site

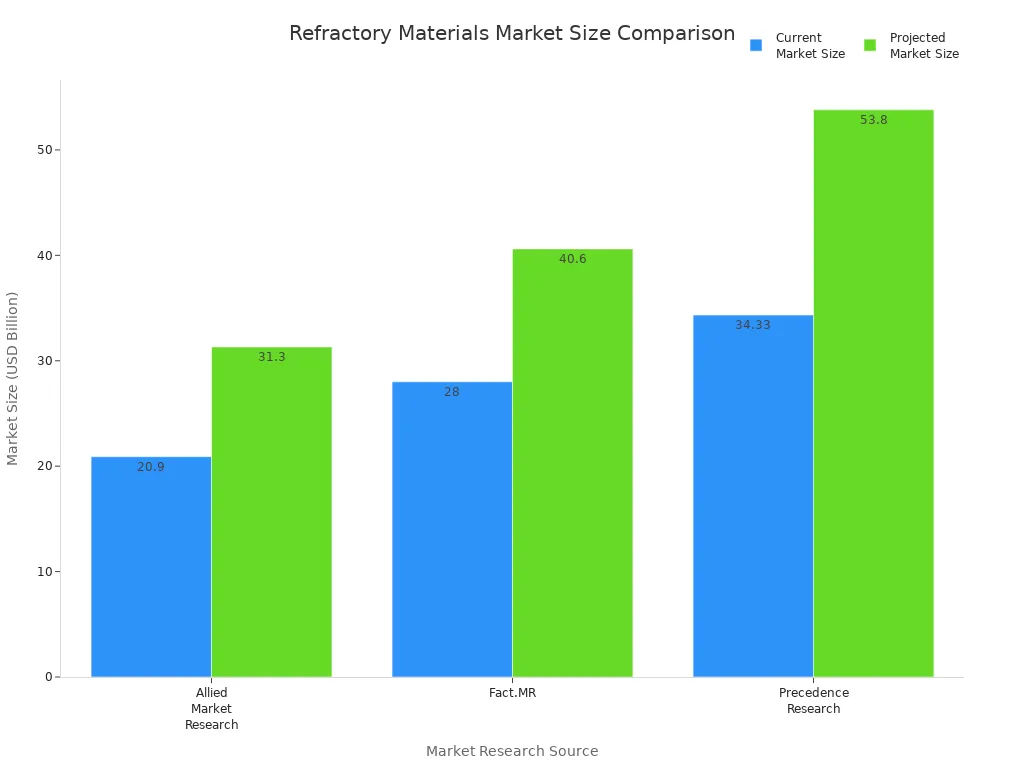

Refractory materials are very important for industry growth. The global refractory market is growing slowly but steadily. Asia-Pacific is growing the fastest because of more factories and high need for monolithic refractories. Steel, cement, and petrochemical industries now like monolithic refractories. They choose them because they are flexible and save energy. Companies spend money on better refractories to keep up with new ways of making things. They also want to help the environment. The chart below shows how the market may grow and which regions lead:

Industry leaders should think about how these changes in refractory materials and refractories will change their work and how well they compete.

Monolithic refractories are flexible and have no joints. They can fit any furnace shape. They last longer than regular bricks. They can handle high heat, chemicals, and wear. This helps factories save energy and spend less on repairs. It is faster and easier to install and fix monolithic refractories. This means less downtime and lower labor costs. New technology and eco-friendly binders make these materials stronger. They are also smarter and better for the environment. The refractory industry has some problems. There are supply issues and not enough skilled workers. But the industry grows by using recycling and digital tools.

Monolithic refractories are a big step forward in refractory materials. They are different from shaped refractories. They do not have a set shape before use. Factories send these materials in loose or bulk form. Workers put them right onto furnace linings, kilns, or reactors. This makes a smooth lining with no joints. It helps the lining last longer and work better.

Monolithic refractories have some special features:

They have a microporous structure. The pores are about 1-2μm, much smaller than in shaped bricks. This makes them stronger and helps them handle heat changes.

The small pores cut down heat radiation by up to 30%. This helps keep heat inside better.

Their structure stops slag from getting in, so they resist corrosion more.

They are plastic, so they can bend a little to release stress. This keeps them from breaking.

You can spray, ram, cast, or mold them. These ways are not like putting in bricks.

Monolithic refractories make building faster and fixing easier. They save money because they use raw materials well and cut down on downtime.

They do not have weak joints, so they work better in tough places.

Since they are not shaped, they take up less space and are easier to move.

Monolithic refractories are now the top pick for industries that want flexibility, speed, and better results in hot places.

There are different types of monolithic refractories. The type depends on what they are made of and how you use them. Each type is good for certain jobs, like making steel or fixing furnaces. The table below shows the main types and what they are used for:

| Monolithic Refractory Types | Industrial Applications | Regional Market Share / Usage Frequency |

|---|---|---|

| Castable | Steelmaking, high-temperature zones | Widely used; Asia-Pacific leads (>50%) |

| Ramming | Arc furnace bottoms, steelmaking | Common in Asia-Pacific |

| Patching | Repairs, localized damage | Usage frequency varies |

| Coating | Surface protection | Usage frequency varies |

| Refractory Mortars | Sealing, bonding | Usage frequency varies |

| Insulating Castables | Furnace insulation | Usage frequency varies |

| Plastic | Irregular surface repairs | Usage frequency varies |

| Gunning & Patching Mortars | Fast repairs in ladles, vacuum systems | Usage frequency varies |

Castable refractories, like high alumina castable and light-weight castables, are used the most. They are popular because they are easy to use and work in many places. Ramming mixes and plastic refractories are good for certain repairs and linings. Gunning materials and patching mortars help fix things fast, so work does not stop for long.

Monolithic refractories keep getting better. They help industries work faster, safer, and with more choices.

Monolithic refractories are very important in today’s factories. They work well in places with high heat and tough conditions. These materials are different from old-style refractory bricks. They have special features like handling high heat, fighting off chemicals, and not wearing down easily. They also do not break when the temperature changes fast. Knowing about these features helps workers pick the best material for their jobs.

One big feature is that monolithic refractories can take a lot of heat. They do not lose their shape or get weak when it is hot. Castables have gotten better over the years. Makers use less calcium oxide to help them last longer in hot places. Low-cement castables last longer but can get weaker between 538°C and 982°C. This happens because the material changes inside. If the heat goes above 1400°C, some castables can lose strength because sticky liquids form. Gel-bond castables are stronger in the heat than cement ones. Dry vibratable types make a strong bond when heated above 1200–1300°C. This makes them good for hard jobs.

Old bricks like silica bricks melt at about 1713°C. High alumina bricks get stronger as they have more alumina. Zirconia refractories stay strong even above 1500°C. Most monolithic refractories can take heat up to or above 1400°C. But they often have more holes and are not as strong as bricks made from the same stuff. Newer types like gel-bond castables help close this gap.

Note: How well monolithic refractories handle heat depends on what they are made of and how they are put together. Picking the right one helps furnaces, kilns, and reactors work well.

There are rules for testing how much heat these materials can take. Some common tests are:

ASTM C975-87(2020): Pressing ramming products to make test pieces

ASTM C862-16(2020): Casting concrete to make test pieces

ASTM C903-15(2020): Cold gunning to make test pieces

ASTM C973-87(2020): Pressing gunning products to make test pieces

ASTM C974-87(2020): Casting castable products to make test pieces

ASTM C865-22: Firing concrete test pieces

ASTM C133-24: Testing how much force they can take before breaking

ASTM C16-03(2025): Testing shapes under heavy loads at high heat

ASTM C1099-07(2025): Testing carbon-containing materials at high heat

The ASTM C583-15(2021) test checks how much force a piece can take at high heat. It bends the piece to see if it breaks. This shows how well the material holds up when it is hot. These tests make sure the materials are good enough for tough jobs.

Monolithic refractories do not react easily with chemicals. In factories, they face gases, liquids, and solids that can eat away at them. Chemicals like acids, ash, or melted slag can cause damage. Newer monolithic refractories use special mixes and things like colloidal silica. This helps stop bad stuff from getting inside. It also helps them last longer and not break down.

| Aspect | Details |

|---|---|

| Corrosion Resistance | Monolithic refractories do not get damaged by harsh chemicals. They last a long time in places with bad gases, liquids, or solids. |

| Composition | They are made from things like alumina and aluminum silicate. These help them take heat and fight off chemicals. Silica powder makes them even better. |

| Industrial Applications | They are used in places like metal, chemical, glass, and cement factories. These places have lots of chemicals. |

| Performance Enhancements | New ways of making them and adding special things help stop chemicals from getting in. This makes them last longer. |

| Temperature Resistance | They can work in heat up to 3000°C. They stay strong and do not break down, even when it is very hot. |

Monolithic refractories also do not wear down easily. Their tight structure and chosen parts help them stand up to rubbing and scraping. This is important in places like steel, cement, and glass factories. There, the materials get hit by moving solids and melted stuff all the time.

The main ways monolithic refractories get damaged in furnaces are:

Slag with CaO, Al2O3, and SiO2 can hurt magnesia-based refractories.

Melted iron and slag can get inside and break down the lining.

Layers like spinel can form when MgO and Al2O3 react.

Moving melted slag and iron can push deeper into the lining.

Melted steel, slag, and other things together can make the lining wear out faster.

In cement kilns, things like K2O, SO3, CaO, and Cl− can make liquids inside the lining. These liquids cause more damage and build-up. More SiC in the lining helps stop this. Using different fuels in cement plants can make more build-up and damage, so the lining does not last as long.

Tip: Picking monolithic refractories that fight chemicals and wear helps linings last longer and saves money on repairs.

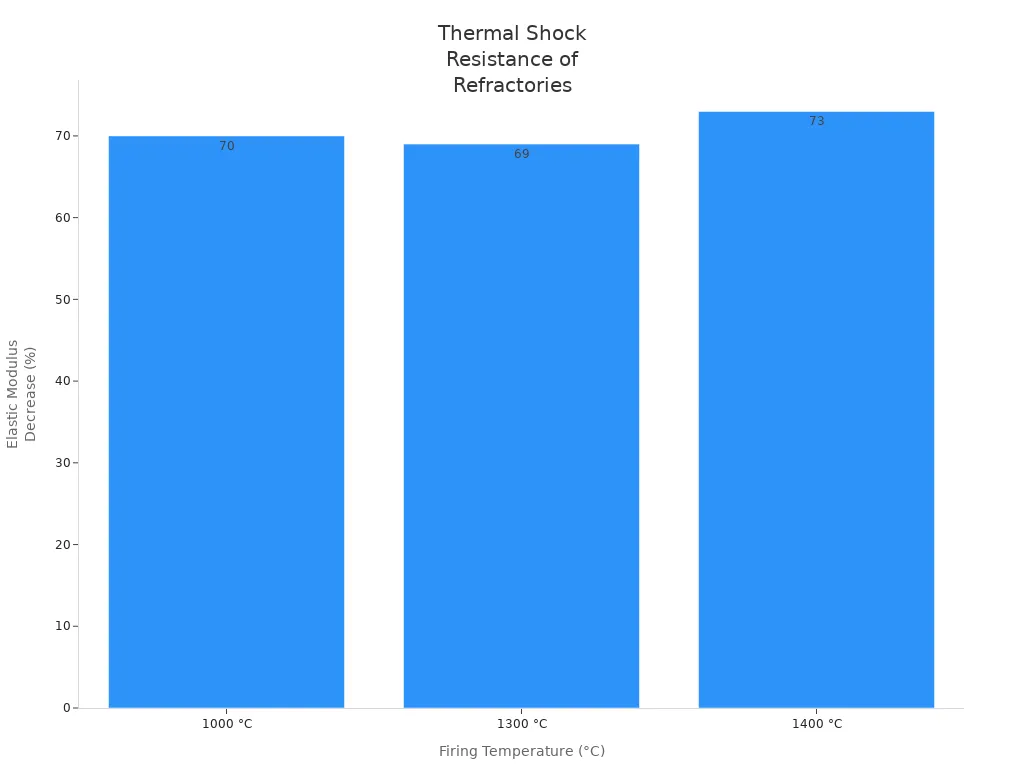

Monolithic refractories can handle quick changes in temperature. This is important because they often get hot and cold fast. If they cannot take it, they might crack or break. Alumina-based castables are good at handling these changes. After 30 water-quenching tests at a 900°C difference, their elastic modulus drops by about 69–73%. Things like mullite and tiny cracks inside help them take in stress without breaking.

The chart above shows how the elastic modulus changes after many hot and cold cycles. Even after 30 cycles, the materials do not break. This means they can work in tough places. Mullite and a tight structure help keep them strong and stop cracks from growing.

Corrosion resistance is also very important. Monolithic refractories must not get eaten away by melted metals, slag, or other bad things. Using pure materials, good bonding, and things like silica powder helps them fight off corrosion. They keep their shape and work well, even when there are lots of chemicals around.

Note: Monolithic refractories get even better when used at high heat. Tiny cracks, what they are made of, and a tight structure all help them handle quick temperature changes and fight off corrosion over time.

Monolithic refractories are easy to install. Workers put them right onto furnace linings. They use casting, gunning, or spraying. There is no need for special brick shapes. Bricklaying is not needed. Wet shotcrete and similar methods make installation fast. This helps factories work more and earn more money. Repairs are quick with monolithic refractories. Sometimes, repairs happen while the furnace is still running. This saves time and lowers labor costs. But these refractories may need more maintenance than regular ones. They crack more often, so fixing them can cost more later. Still, they cost less at first and are quick to install. Many industries like using them for these reasons.

Monolithic refractories do not have joints. This is a big advantage. Fewer joints mean fewer weak spots. Steel or slag cannot get in easily. Their dense structure makes them strong. They resist heat shock, scraping, and corrosion. High alumina castables stay stiff and strong. They work well in tough places like steel furnaces. Casting makes linings with high crushing strength. This helps stop cracks and breaks. The strong structure makes the lining last longer. It also keeps workers safer by lowering sudden failure risks.

The jointless design lowers failure points.

Dense structure fights off damage.

Big, complex shapes need few joints.

Strong and tough linings work better.

Monolithic refractories fit many furnace shapes. Workers install them on-site to match any shape. This makes them good for odd or tricky equipment. Quick patching is possible, so repairs are fast. Light-weight castables keep heat in better. They cut heat loss by over 22%. New mixes save even more energy, over 25%. Many new products focus on fast installation and less fixing. Some linings have smart systems to warn when repairs are needed. This cuts downtime by over 20%. These features make monolithic refractories a top pick for industries that want to work fast and adapt easily.

| Feature | Monolithic Refractories | Shaped Refractories |

|---|---|---|

| Application Method | On-site casting, gunning, ramming, spraying | Preformed bricks, manual installation |

| Geometric Flexibility | High - fits complex shapes | Limited - best for regular shapes |

| Installation Time | Fast, allows quick repairs | Slow, needs bricklaying |

| Repair & Maintenance | Localized patching, minimal downtime | Full section replacement |

Tip: Monolithic refractories install quickly, stay strong, and fit many needs. These benefits help industries save time and money.

There have been big changes in refractory technology lately. Makers now use nanotechnology, composite powders, and refractory alloys. These help with heat control and make materials stronger. High alumina refractories and insulating products like silicon carbide help factories deal with very high heat and quick temperature changes. Smart refractory materials last longer and keep heat better. This means factories stop less often and work better in steel, cement, and non-ferrous metal industries.

Industry leaders spend money on research to make better and greener refractory products. Automation and digital monitoring are now important in making and using refractories. These systems watch how refractories work and tell when repairs are needed. This helps factories avoid sudden problems. Companies also use binders that fire at lower temperatures and resins that are better for the environment. These choices save energy and cut down on pollution. New ways of making refractories, like mechanochemical alloying and molten salt synthesis, create advanced spinel refractories with better features.

Smart refractory materials last longer and keep heat better.

Automation and digital monitoring make installation and repairs easier.

Nanotechnology and composite powders help fight heat and corrosion.

Making refractories in a green way is now very important. Makers use eco-friendly binders and raw materials to help the planet. Sodium-based geopolymer binders, made from metakaolin, set fast and are very strong. These binders work better than old calcium aluminate cement after being fired at high heat. Geopolymers can be made from waste from factories, which helps lower carbon footprint and saves energy.

| Binder Type | Setting Time (hours) | Mechanical Strength (MPa) | Flexural Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|

| Sodium Geopolymer | ~11 | 50.4 | 34.89 | 94.22 |

| Potassium Geopolymer | ~19 | 25.6 - 31.4 | N/A | N/A |

| Calcium Aluminate Cement | N/A | N/A | 22.56 | 44.01 |

Thermosetting resins, like novolaks and resoles, are used instead of coal-tar pitches. These resins are safer for the environment. They come from things that can grow back and help make more carbon after heating. Oxy-fuel firing and low-temperature binders also help lower pollution. Factories that use green refractories use less energy and make less pollution.

Eco-friendly refractories help factories follow rules and support world goals for a cleaner planet.

Recycling is becoming more important in the refractory industry. In Europe, over 28% of refractory products now use recycled materials. In 2024, Germany reused more than 1.5 million metric tons of refractories. North America and Asia-Pacific are building more recycling centers. Recycling alumina/ZrO2 and MgO/ZrO2 refractories helps cut down on landfill waste and carbon emissions. Recycling more and moving materials shorter distances makes these benefits even bigger.

Still, some places do not recycle much. For example, metal makers in Missouri recycle less than 1% of used refractories. Most of it goes to landfills. There need to be better reasons to recycle, both for money and the environment. Making refractories last longer also helps lower carbon emissions over time. New monolithic refractories last longer and work better. This means factories stop less and fix things less often, which is better for the planet.

♻️ Recycling and using refractories well help make industry cleaner and greener for the future.

Monolithic refractories are very important in hot factories. They help protect machines and make work better in many areas. The table below shows which industries use them most and why they matter:

| Industrial Application | Market Share / Importance | Key Role / Application Details |

|---|---|---|

| Iron and Steel Industry | Biggest user; most important sector | Keeps furnace linings safe; helps make steel faster; used in blast furnaces, electric arc furnaces, and ladles. |

| Cement Industry | Very important | Saves energy and cuts repairs in rotary kilns and preheaters at high heat. |

| Glass Manufacturing | Also important | Makes furnaces last longer and keeps glass quality high; needed for solar glass panels; keeps heat even. |

| Non-ferrous Metals Industry | Smaller but getting bigger | Used in making aluminum and copper; needed for electronics and cars. |

| Energy Sector | Uses a lot | Used in power plants and waste burners; helps in hot burning chambers and boilers. |

| Chemical Industry | Important user | Needed for hot and harsh places in reactors and kilns. |

| Other Sectors (Automotive, Petrochemicals) | Smaller but many uses | Used to make engine parts and other things that need high heat. |

Asia-Pacific is the top market. This is because steel, cement, and glass factories are growing fast there.

How people use monolithic refractories has changed lately. Factories now like them for being flexible and working well. Some main trends are:

The steel industry uses more than 65% of all refractories. People want lighter and energy-saving products as steel making grows, especially in Asia-Pacific.

Cement factories now use more high-alumina bricks and monolithic refractories. Cities growing and new factories make this happen.

Petrochemical companies need linings that fight off chemicals and corrosion. Better refractories help keep their machines safe.

Many factories pick monolithic refractories because they are easy to put in and work well.

Digital tools and caring for the planet help make new products. Factories want things that last, save energy, and are good for the earth.

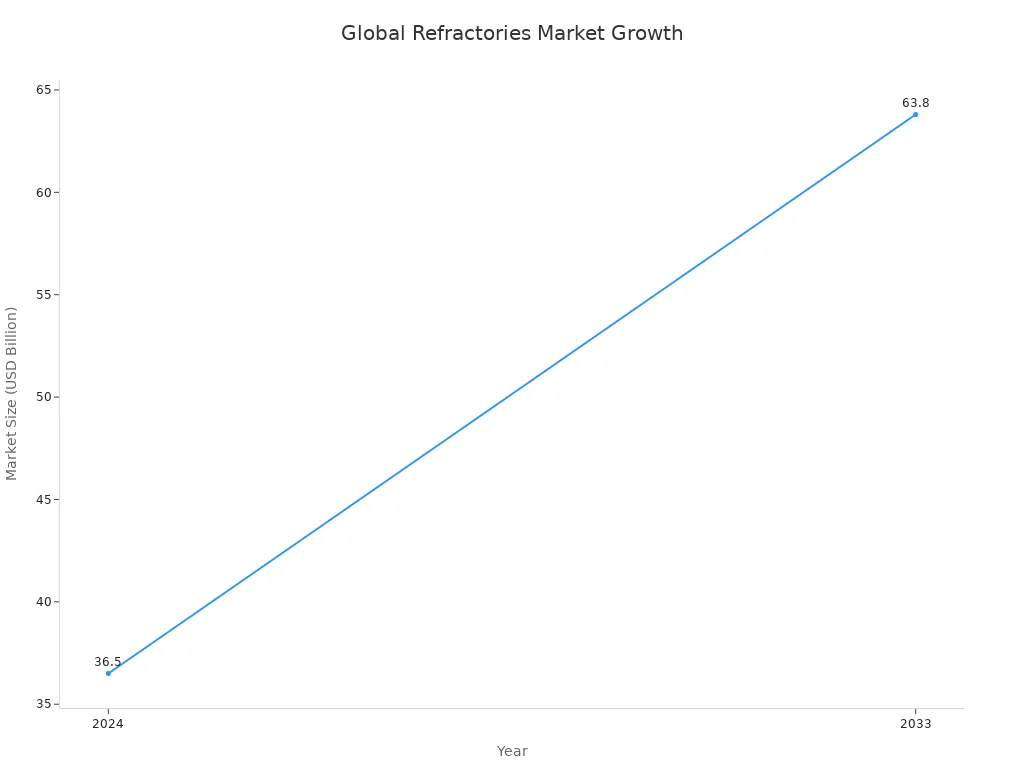

The world market for refractories is getting bigger. Monolithic and unshaped types are growing the fastest. The chart below shows how the market may grow:

Steel making in India and China keeps going up. North America is seeing more work in petrochemical and energy areas. Companies spend money to make refractories better and greener.

The refractory industry has some big problems:

Prices for magnesia, alumina, and graphite change a lot. World events and shipping problems cause this.

Delays in the supply chain, like crowded ports and not enough drivers, slow down making refractories.

There are not enough skilled workers. Older workers retire, and not many young people join.

The steel industry goes up and down, so it is hard for companies to plan.

New ways to make steel need different refractories. Companies must change fast.

Rules for the environment mean cleaner tech and better waste control. This costs more and is risky for companies.

Customers want refractories that last longer and can be watched in real time. This means companies must spend more on research and digital tools.

Cybersecurity is a bigger risk as factories use more computers.

Note: Companies try to solve these problems by using more suppliers, recycling, and working with rule makers. Smart tech and good teamwork help them do well for a long time.

Industry leaders notice big changes in monolithic refractories. Companies want flexible solutions. These save time and help work go faster. New technologies make factories work better. Eco-friendly binders help the environment. Digital tools help factories follow rules.

Experts say to focus on new ideas and saving energy.

Watching market trends is important.

Learning and changing quickly keeps businesses strong.

Smart choices and learning all the time help companies do well in the refractory industry.

Monolithic refractories protect furnaces, kilns, and reactors in factories. They are used in steel, cement, and glass industries. These linings are strong and have no joints. They can handle high heat and chemicals. Many factories use monolithic castable refractory and monolithic refractory cement. These help with quick repairs and save energy.

Monolithic castable refractory is a ready-mix that workers pour or pump. Monolithic refractory cement is the binder that holds the mix together. Both make tough monolithic refractory linings. Castables are better for tricky shapes because they are flexible.

Industries like monolithic refractory materials because they go in faster. They fit any shape and help cut down on work stops. Monolithic refractory linings have no joints. This makes them last longer and resist damage better than bricks.

Yes, many companies recycle monolithic refractories. They crush old linings and use the pieces in new products. Recycling helps save money and is good for the planet.

Monolithic refractory linings stop heat from escaping. They make a thick, smooth wall that keeps heat inside. New monolithic castable refractory and insulating mixes keep furnaces hotter. This saves energy and lowers fuel costs for factories.