Views: 0 Author: Site Editor Publish Time: 2025-08-19 Origin: Site

Green thermal insulation helps stop heat from moving around. You use insulation to keep heat in or out. This makes your building work better. Many industries pick materials that help the planet. These materials also make air inside cleaner. Some common green choices are:

Sheep’s wool: It can grow back, breaks down, and slows fire.

Cotton or denim: Made from old clothes, keeps bugs away.

Cellulose: Made from used paper, helps cut down trash.

Hemp fiber: Grows fast and keeps heat in or out well.

Icynene spray foam: Uses castor oil and saves energy.

You find these materials in factories and homes.

Green thermal insulation uses natural or recycled stuff. It helps save energy and keeps the environment safe in factories and buildings.

Picking insulation with high r-value and safe materials helps control heat. It also makes air cleaner and keeps workers safe.

Green materials like sheep’s wool, hemp, and cellulose give strong insulation. They also help cut down on pollution and waste.

Putting in insulation the right way and sealing it stops heat from escaping. This helps save money on energy bills.

Using green insulation helps factories follow safety rules. It also lowers costs and helps make the planet healthier.

Green thermal insulation helps control heat in factories and other big buildings. It also helps protect the environment. You use it to keep heat inside or outside your building. This saves energy and helps the planet. Green insulation is different from regular insulation. It uses materials that are renewable, recycled, or not harmful. These materials help you reach environmental goals. They also make the workplace safer.

When you pick green thermal insulation, you look for some important things. These features make it good for the planet and useful for factories:

Renewable or Recycled Materials

Green insulation can be made from cotton, sheep’s wool, cellulose from old paper, cork bark, and denim. These materials help reuse things and cut down on waste.

Non-Toxic Composition

Green insulation does not have bad chemicals or VOCs. This means the air inside is cleaner and safer for workers.

Biodegradability and Recyclability

Many green insulation products break down on their own or can be used again. This helps keep trash out of landfills and protects nature.

High Energy Efficiency

Green thermal insulation often has a high r-value. This means it stops heat from moving. You use less energy to heat or cool your building. This saves money and resources.

Moisture Regulation

Some materials, like sheep’s wool, can take in and let out water. They do this without losing their ability to stop heat. This helps stop mold and keeps the building healthy.

Durability

You want insulation that lasts a long time. Green options often stay strong for many years. This means you do not have to replace them often.

Low Carbon Footprint

Making green insulation uses less energy and makes less pollution. Hemp, for example, takes in CO2 and grows fast. This makes it a good choice for the planet.

Tip:

If you want insulation that makes air cleaner and has fewer toxins, pick products that say non-toxic and VOC-free.

Here is a table that shows how green insulation is different from regular insulation:

| Feature | Green Insulation | Conventional Insulation |

|---|---|---|

| Raw Materials | Renewable/Recycled (cotton, wool, hemp, cellulose) | Mineral/Fossil-based (glass wool, EPS, PUR/PIR) |

| Toxicity | Non-toxic, low VOCs | May contain chemicals/VOCs |

| Carbon Footprint | Low or negative | High |

| Biodegradability | Yes | No |

| R-Value Stability | Stable over time | May drift (foam) |

| Moisture Control | Good (wool, hemp) | Variable |

| Durability | Long-lasting, reusable | Can degrade, pest risk |

You can see that green thermal insulation is good at stopping heat and saving energy. It also lets air move, stops mold, and blocks noise. Hemp insulation, for example, does not burn, is not toxic, and has an r-value of about 3.5 to 3.7 per inch. You can use it in factories and homes.

You find green thermal insulation in many types of factories. These places use insulation to save energy, follow rules, and keep workers safe:

Manufacturing

Factories use insulation to keep heat in boilers, pipes, and tanks. This stops energy from being wasted and helps machines work better.

Chemical Processing

Chemical plants need good insulation to control heat and stop accidents. Green insulation helps meet safety rules and lowers pollution.

Construction (Residential and Commercial)

Builders use green insulation in homes, schools, hospitals, and offices. This makes buildings more comfortable and cuts energy bills.

Aerospace and Automotive

Planes and cars use insulation to control heat and block noise. Green materials help companies follow strict environmental laws.

Energy and Marine

Power plants and ships use insulation to protect machines and save fuel. This helps the planet and lowers costs.

Note:

Rules like LEED and the EU Energy Performance of Buildings Directive make companies use green insulation. You can get money from the government and other help if you use it.

Here are some reasons why factories pick green thermal insulation:

Follow rules (LEED, USGBC, EU directives)

Save energy and pay less for power

Help the planet and lower pollution

Make the workplace safer and air cleaner

Use new technology (aerogels, vacuum panels, phase change materials)

Get money and help from green building programs

You see green insulation in projects that fix old buildings, smart buildings, and upgrades. Builders and managers use it to meet green goals and make buildings work better. You can use green insulation in new buildings or when fixing old ones.

Green thermal insulation helps save natural resources and meet today’s green goals. You get strong insulation, a good r-value, and reliable heat control. These benefits make green insulation a smart pick for factories and homes.

Thermal insulation helps control heat in factories. It keeps heat where you want it. It stops heat from getting out. This saves energy and keeps workers safe. To know how insulation works, you must learn how heat moves. Heat moves in three main ways: conduction, convection, and radiation. Each way works differently in factories.

Heat always goes from hot places to cold places. In factories, heat can leave hot pipes, tanks, or machines. You lose energy if you do not stop this. Here are the three ways heat moves:

Conduction

Conduction is when heat moves through solids. If you touch a hot metal pipe, you feel heat. The heat travels through the metal. How fast heat moves depends on the material. Metals let heat move fast. Wool or foam slow heat down. The formula for conduction is:

Q = (k · A · (Thot – Tcold)) / d

Adding insulation makes the layer thicker. It also uses materials that slow heat. This makes heat move slower.

Q is the heat transfer rate.

k is the thermal conductivity.

A is the area.

Thot and Tcold are the temperatures.

d is the thickness.

Convection

Convection moves heat through air or water. In factories, warm air rises from hot things. Cooler air comes in to take its place. This makes air move and carry heat away. You see this near pipes or tanks. The formula for convection is:

Q = hc · A · (Ts – Tf)

Insulation blocks air from moving. It traps air and stops these currents.

hc is the convective heat transfer coefficient.

Ts is the surface temperature.

Tf is the fluid temperature.

Radiation

Radiation sends heat as invisible waves. All things give off some radiant heat. Hot things like boilers or ovens give off more. Radiation does not need air or touch to move heat. The Stefan-Boltzmann law explains this:

P = e · σ · A · (Tr^4 – Tc^4)

Shiny barriers help bounce radiant heat away. They keep heat in or out as needed.

P is the power of radiated heat.

e is emissivity.

σ is a constant.

Tr and Tc are the temperatures of the radiator and the surroundings.

Tip:

To save energy, you must stop all three ways heat moves. Good insulation blocks conduction, convection, and radiation.

In factories, all three ways work together. Hot pipes lose heat by conduction, convection, and radiation. Without insulation, you waste energy and make things unsafe.

You need the right materials for good thermal insulation. Insulation works by using things that slow heat down. The best materials have low thermal conductivity and high thermal resistance. You often see wool, foam, or special fibers in factories.

How do these materials work?

Most insulation traps air in tiny spaces. Air does not move heat well. These spaces slow down conduction. Foam panels have many small bubbles. Even if you press them, the air stays inside. This makes foam good for many uses.

Some insulation has layers. Bubble sheets have air pockets between shiny foil. The air pockets stop conduction and convection. The foil reflects radiant heat. This keeps heat where you want it.

Factories also use radiant barriers. These barriers have shiny surfaces and need an air gap. The air gap stops radiant heat from moving to cooler things. You see this in big plants where radiation loss is high.

Here is a table to show how different insulation materials work:

| Material Type | How It Works | Best For |

|---|---|---|

| Wool/Fiber | Traps air, slows conduction | Pipes, tanks, walls |

| Foam Panels | Air bubbles, blocks conduction | Ducts, equipment, containers |

| Bubble Sheets | Air pockets + foil, blocks all three | Roofs, ducts, large surfaces |

| Radiant Barriers | Reflects heat, needs air gap | Ovens, boilers, hot tanks |

Note:

The r-value shows how well insulation stops heat. A higher r-value means better resistance. You want a high r-value for best results.

In factories, you must think about where to put insulation. Hot pipes, tanks, and ovens all need it. Make sure insulation fits tight. Gaps let heat out and lower the r-value.

You also need to think about safety and the planet. Many green insulating materials use recycled or renewable things. They do not give off bad chemicals. This keeps workers safe and helps the earth.

Why does this matter in industry?

Factories use lots of energy. If you lose heat, you spend more money and use more fuel. Good insulation keeps heat where you need it. It also keeps workers safe and machines working well.

You save energy and money.

You meet safety rules.

You help the planet.

You get better control over your work.

Callout:

Always check your insulation for damage or gaps. Even small leaks waste energy and lower your r-value.

When you pick insulation, look for materials that trap air, block movement, and reflect heat. Make sure you install them right. This gives you the most benefit and keeps your factory working well.

When you pick green insulation for your factory, you have many choices. Each kind helps you use less energy and care for the earth. You will see recycled things, natural fibers, and new ideas used for thermal insulation in factories.

You can make insulation from recycled things. Cellulose insulation comes from old paper. It keeps heat in or out and does not pollute much. The world makes over 300 million tonnes of cellulose each year. This is much more than the 25 million tonnes needed for insulation. So, you always have enough old paper for your work. Cellulose insulation lowers carbon and has a high r-value.

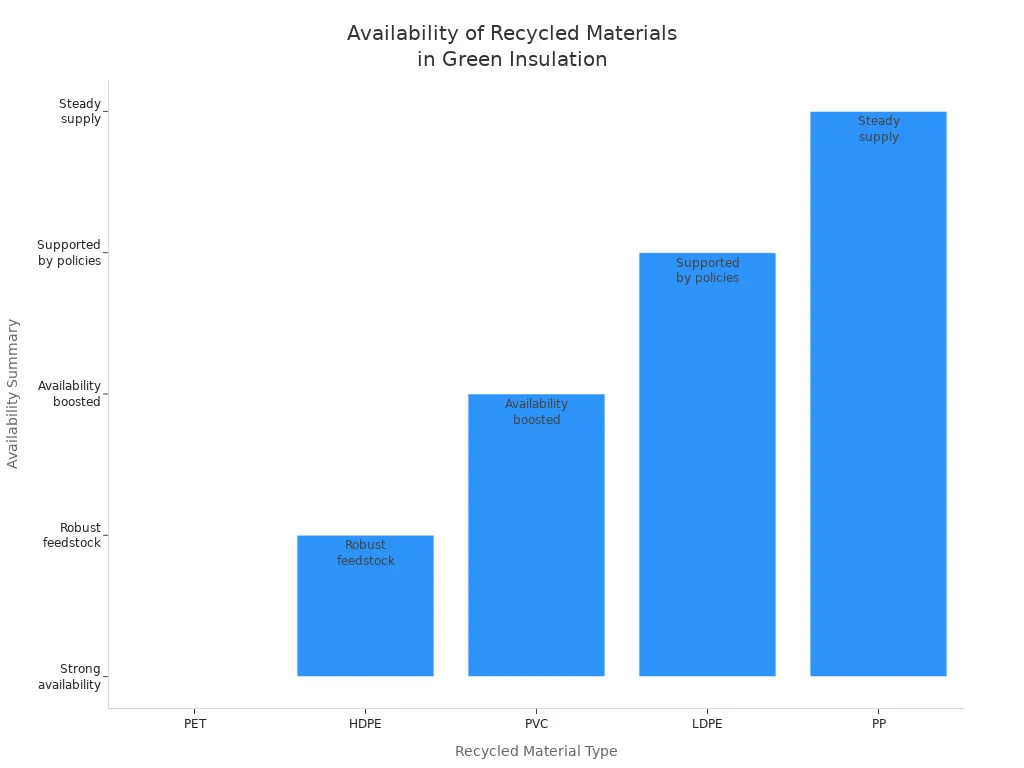

Recycled plastics are important too. You will find PET, HDPE, PVC, LDPE, and PP in insulation. These plastics come from bottles, packages, and other trash. Recycling programs in Asia Pacific, China, North America, and Europe give a steady supply. You can look at the chart below to see how much recycled plastic is ready for green insulation.

Here is a table that shows how recycled plastics help you reach green goals:

| Recycled Material Type | Use in Insulation | Availability |

|---|---|---|

| PET | High thermal performance | Strong, global |

| HDPE | Common in insulation | Robust, global |

| PVC | Window frames, panels | Boosted by recycling |

| LDPE | Plastic insulation | Supported by policies |

| PP | Insulation products | Steady supply |

When you choose recycled insulation, you help the earth. You also follow green building rules and save money.

Natural insulation gives you many good things. You will see sheep’s wool, hemp, cork, cotton, flax, wood fiber, and mycelium used in factories. These come from things that grow back and are better for the earth than fake ones.

Sheep’s wool insulation has an r-value close to fake materials. It soaks up water, slows fire, and blocks sound. You can put it in without special tools.

Hemp insulation has an r-value of about 3.5 per inch. It stops mold and allergens, so your workplace is healthier.

Mycelium insulation comes from fungus and has an r-value around 3 per inch. It does not burn and works in walls, ceilings, and floors.

Cellulose insulation, made from old paper, fits around pipes and tanks. It slows fire and blocks noise.

Cork and wood fiber insulation store carbon and help control water in the air.

Natural insulation does not let out bad chemicals. You get cleaner air and better indoor quality. You also help the earth by using things that grow back and lowering your carbon footprint.

You might pay more at first for natural insulation, but you get health and green benefits. These materials often last longer and work as well as fake ones.

You will see new green insulation in factories today. Spray foam insulation, aerogel, vacuum insulation panels, mineral wool, and thermal acoustic insulation all have special uses.

Spray foam insulation has high thermal resistance and stops air leaks. You use it in cold storage and places that need tight temperature control. Aerogel insulation has the highest r-value and very low thermal conductivity. You can use thin layers in small spaces like pipes and labs. Vacuum insulation panels save space and give strong thermal resistance, great for fridges and clean rooms.

Thermal acoustic insulation helps control heat and noise in factories and power plants. You protect machines, lower energy bills, and keep workers safe. Mineral wool and new spray foams slow fire and keep your building safe.

Yufeng Refractory makes ceramic fiber boards, blankets, and modules for factories. These products have high r-value, great thermal insulation, and fire resistance. You use them in kilns, furnaces, and hot equipment. Their ceramic fiber insulation helps you save energy and meet safety rules.

New green insulation helps you fix hard problems in factories. You get better heat control, less noise, and more fire safety.

You can save a lot of money with green thermal insulation. The National Insulation Association says good insulation can save over $3.6 billion in energy every year. It also helps cut greenhouse gas emissions by 83 billion pounds. If you do not use insulation, you waste three times more energy. You also pay higher bills. Upgrading insulation means you use less energy for heating and cooling. You spend less on fuel and electricity. Your equipment lasts longer because it stays at steady temperatures. You get better control and higher efficiency.

Experts use special programs to check your insulation. They look for places where energy is lost. They show you how much money you can save. These reports help you see why upgrades are important. Most insulation investments pay off fast. For example, steel building owners have cut energy costs by half after adding new insulation. Many get their money back in just two years. You can expect to save money and lower costs for your equipment’s life.

Green insulation helps you follow strict safety rules. It keeps workers safe and protects your facility. Many insulation materials are treated to resist fire and pests. You can pick options like cellulose, cotton, mineral wool, and spray foam. These materials meet codes such as the Oakland Green Building Ordinance and Title 24. You need certified professionals to install insulation. You must keep records to show you follow the rules.

Here is a table that shows how insulation types meet safety standards:

| Insulation Type | Safety Feature | Compliance Standard |

|---|---|---|

| Cellulose | Fire retardant treatment | Oakland Green Building Ordinance |

| Cotton (Denim) | Borate for fire/pest control | Title 24 |

| Mineral Wool | Fire resistance up to 1800°F | Title 24 |

| Spray Foam | Airtight, fire safety measures | Oakland Green Building Ordinance |

You should choose insulation with high r-value, low VOCs, and safe ingredients. Federal guidelines like EPA’s rules and ENERGY STAR help you pick good products. This keeps your workplace healthy and helps you follow the law.

You may face some problems when you install green thermal insulation. Some people think reclaimed insulation is not safe or strong. Studies show reclaimed materials keep their r-value and work well. You can buy them for less money and get tax benefits. Another myth is that thermal bypasses do not matter. In fact, they cause up to 93% heat loss. You need to seal gaps and install insulation carefully.

You might worry about upfront costs. Green insulation often costs more at first. But you save much more over time. Life-cycle cost analysis shows energy savings make up for the first expense. You also get help from government programs. Strict building codes and energy rules push companies to use better insulation. North America and Europe lead because of these policies.

Here are some common myths and facts:

Reclaimed insulation is safe and saves money.

Good installation stops heat loss and boosts efficiency.

Government incentives help lower your costs.

Tip: Always check your insulation for gaps and damage. Good installation gives you the best results.

You need to find out where your building loses heat. Start by having experts check your equipment. They look at things like pipes, tanks, and boilers. Use special cameras to see spots with bad insulation. These cameras show where heat escapes. Use tools to guess how much energy you lose each year. Many factories use the Tipcheck method to check insulation. Always think about insulation when you build or fix things. Try to follow rules like EN 17956. Pick materials that help your green goals.

Steps to assess your insulation needs:

Get an expert to check for heat loss.

Use cameras to find weak spots.

Figure out yearly energy loss with tools.

Use the Tipcheck method for a close look.

Plan insulation early in new projects.

Try to meet high standards.

Choose materials that are good for the earth.

Tip: Planning early helps you save energy and money later.

You need to pick the best insulation for your factory. Think about how much heat you want to keep in or out. Some places need to block noise too. Look for materials that save energy and cut pollution. Make sure the insulation keeps your building safe and not too hot. Safety is important, so pick fire-retardant and non-toxic types.

Key criteria for choosing insulation:

High r-value

Good at blocking air and water vapor

Resists moisture

Easy to put in

Makes less carbon

Not too expensive

Safe for people

Has recycled stuff

Use a checklist to compare your choices. Ecolabels can help you decide what is best. Always think about your building’s needs, like fire safety and how long it lasts.

| Criteria | Why It Matters |

|---|---|

| R-value | Stops heat from escaping |

| Air/Vapor Permeability | Controls water in the air |

| Moisture Tolerance | Stops mold from growing |

| Installation Ease | Makes work faster |

| Carbon Emissions | Helps the planet |

| Cost | Keeps spending low |

| Toxicity | Keeps air clean |

| Recycled Content | Cuts down on trash |

You want your insulation to work well for a long time. Pick materials and ways that are better for the earth. Keep your building healthy by controlling air and water. Teach your team to put in insulation the right way. Make sure to line up, fasten, and seal everything. Use insulation that covers all parts to stop heat leaks.

Best practices for installation:

Attach insulation tightly everywhere.

Seal all gaps and holes.

Add air barriers for better results.

Follow the maker’s instructions.

Use the right tools for the job.

Take your time and do not hurry.

Pick what works for your weather.

Check insulation often for problems.

Note: New ideas include smart insulation with sensors, aerogels for small spaces, and natural fibers. These help you save more energy and reach green goals.

When you pick green insulation, you help the earth. Using recycled foam panels and wheat straw cuts down waste. It also lowers carbon in the air. You help local workers and keep materials useful for longer. You can do these things:

Add more insulation to your buildings.

Fix roofs so they stop heat from coming in.

Use energy checks to find where heat escapes.

Choose materials that are good for the planet.

Soon, new rules and smart tech will give you more options for homes and factories.

Green thermal insulation uses things that can be recycled or grow back. It does not have bad chemicals. This helps the earth by making less pollution. The air inside your building is cleaner. Many factories and homes pick green insulation for these reasons.

You think about what your building needs. You look for places where heat escapes. You check the r-value numbers. You choose materials that match your safety and energy plans. You can use a checklist to help you decide:

| Criteria | Importance |

|---|---|

| R-value | High |

| Fire safety | High |

| Cost | Medium |

| Eco-friendly | High |

Yes, green insulation works in homes too. It helps you save energy and keeps the air cleaner. Your family stays healthier. Many people use sheep’s wool, hemp, or cellulose in their houses.

Green thermal insulation can cost more at first. You save money later because your energy bills go down. You might get help from the government. The good things you get over time are worth the higher price at the start.

Check your insulation every year for holes or damage. Make sure it does not get wet. Change any parts that are worn out. Keep notes for safety checks. Taking care of insulation helps it last longer and work better.