Views: 0 Author: Site Editor Publish Time: 2025-08-25 Origin: Site

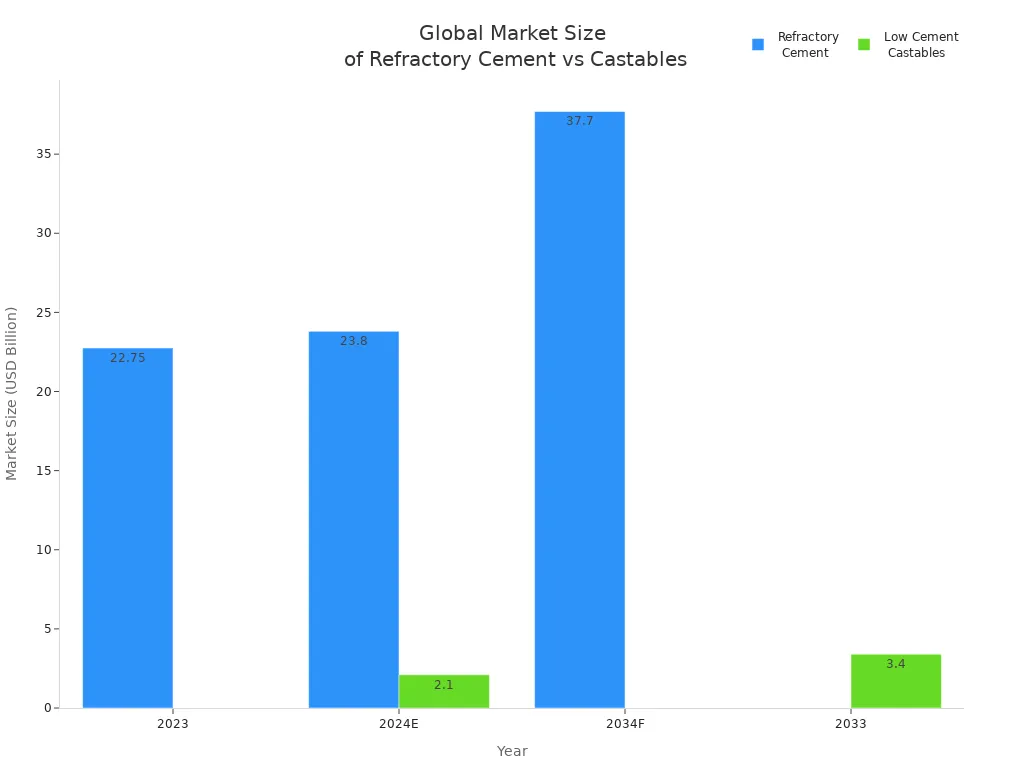

The main difference between refractory castable and refractory cement is what they are made of and how they work. Refractory castable has special materials. These materials help it handle heat better and make it stronger than regular refractory cement. Fire brick and Refractory Brick are very important in places with high heat. They protect buildings from strong heat and damage. Fire brick is great because it can handle heating and cooling many times. This makes it needed in furnaces and kilns. The world market shows this pattern. Refractory cement was worth over $22 billion in 2023. Low cement refractory castables are becoming more popular. They have better features and more people want them in steel and glass factories.

Picking fire brick, refractory castable, or refractory cement depends on how much heat is needed and the working conditions.

Refractory castable is a mix you pour into shapes. It gets hard and protects hot equipment. Refractory cement is a special glue. It sets quickly and holds things together.

Fire bricks are strong blocks. They can handle very high heat. They protect furnaces, kilns, and ovens from damage. They also stop heat from escaping.

Castables are good for making tricky shapes and big linings. They are strong and resist heat and chemicals. This makes them great for hard jobs in factories.

Cement works best for fast repairs and small fixes. It is good for sticking bricks together. But it can get weaker if heated and cooled many times. Castables are stronger for this.

Picking the right refractory material depends on many things. You need to think about temperature and chemicals. You also need to consider stress, how you install it, cost, and safety. This helps make sure you get good heat protection that lasts.

A refractory brick is a special block that can take very high heat. People also call it a fire brick. Factories use these bricks where it gets very hot, like kilns, furnaces, and ovens. The main job of a refractory brick is to keep equipment safe from heat and damage. There are many kinds of firebrick for different jobs. Some common types are fireclay bricks, high alumina bricks, silica bricks, magnesite bricks, chromite bricks, and zirconia bricks. These bricks use materials like bauxite, clay, silica, and magnesite. The material picked depends on the heat and chemicals the brick will face.

| Type of Brick | Composition / Characteristics | Features | Typical Applications |

|---|---|---|---|

| Magnesia Bricks | >85% MgO | High melting point (>2800°C), good for basic environments, moderate thermal shock resistance | Electric arc furnaces, steel ladles, converters |

| Magnesia-Carbon Bricks | Magnesia + flake graphite | Excellent thermal shock resistance, strong slag and erosion resistance | Steelmaking furnaces, EAF sidewalls, BOF, ladles |

| Refractory Insulating Bricks (IFB) | Lightweight, porous | Very low density, low heat storage, not load-bearing | Kiln backup linings, lab furnaces, heat treatment ovens |

| Zirconia Bricks | Zirconia-based, ultra-high purity | Service temp up to 2200°C, high corrosion resistance, expensive | Glass contact zones, special melting furnaces, aerospace, nuclear furnaces |

Refractory bricks have special features that help them work in hot places. They can handle firing temperatures from 900°C up to 1200°C or more. Their bulk density goes up as the temperature rises. This means they get stronger and less porous. Water absorption drops as the bricks get hotter, so they last longer. The color of a fire brick can change with heat. The sound it makes when tapped can show how well it is fired. The strength of refractory bricks depends on what they are made of. For example, bricks with more than 20% alumina may not be as strong. The right amount of water during making helps the brick stay tough.

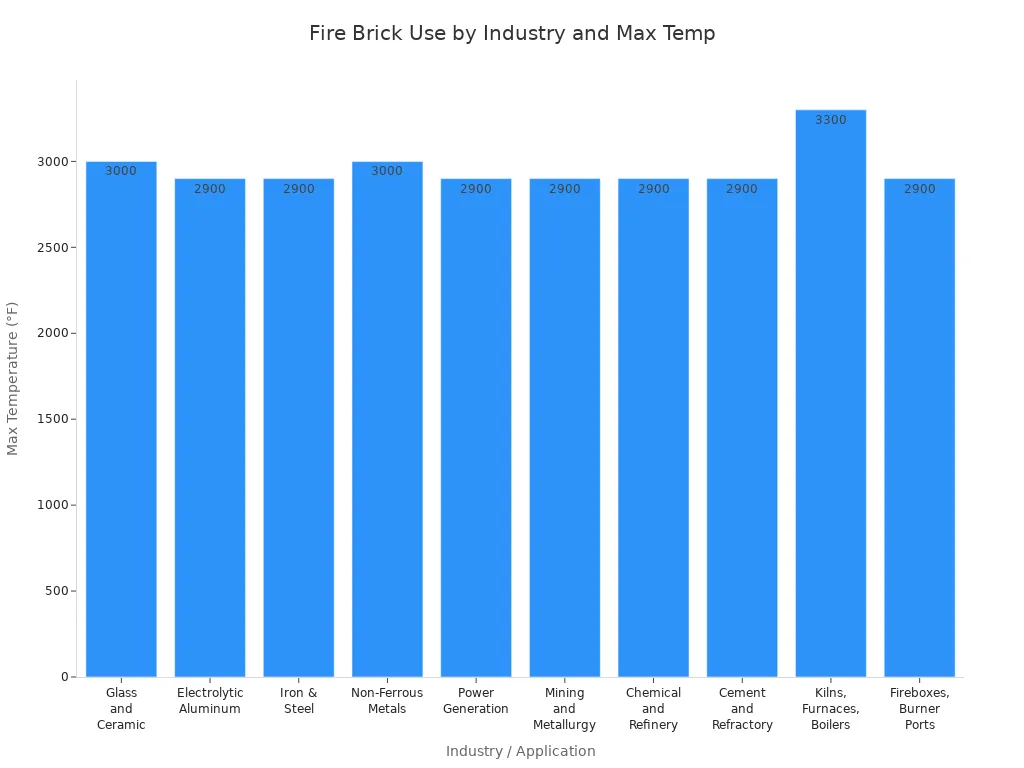

Fire brick is used in many places because it can take high heat and tough conditions. Factories use fire brick in kilns, furnaces, boilers, and ovens. The steel industry uses fire brick in blast furnaces and electric arc furnaces. The glass industry uses it in melting furnaces. Power plants use fire brick in boilers. The cement industry uses it in rotary kilns. People also use fire brick in pizza ovens because it keeps heat steady and safe for cooking. There are two main types of firebrick. Hard bricks are for structure. Soft insulating bricks help keep heat inside kilns. The temperature a fire brick can take depends on its grade. Low-duty bricks work up to 1750°F. High-fired super duty bricks can go above 3000°F. This makes fire brick great for kilns and pizza oven projects.

Refractory castable is a material that does not have a set shape. Workers mix it and pour it where needed. It hardens and becomes a strong lining. There are rules, like ASTM C-64 and ASTM C401-91, that sort castables by what they are made of. Some types have alumina-silica or are made for insulation. Companies make these materials for kilns, boilers, and steel plants. Castables can be heavy, medium, or light. This depends on how they will be used. The main chemicals inside are alumina, silica, ferric oxide, titanium oxide, calcium oxide, magnesium oxide, and alkalies. Some special castables have more alumina or silicon carbide. They also have extra chemicals to help them work better in high heat.

Note: Refractory castables are not the same as plastic refractories. Castables are easier to put in place. They can fit into tricky shapes in kilns and furnaces.

| Property Category | Refractory Castables (Unshaped) | Other Refractory Materials (Shaped Bricks, etc.) |

|---|---|---|

| Form/Shape | Unshaped, takes shape after installation and setting | Shaped, pre-formed bricks |

| Chemical Classification | Acidic, Basic, or Neutral types | Same, but in brick form |

| Physical Properties | Consistency, flow, plasticity, adhesion, resilience | Focus on porosity, bulk density, mechanical strength |

| Structural Properties | Porosity, bulk density, water absorption, permeability | Similar properties |

| Thermal Properties | Thermal conductivity, expansion, specific heat | Similar properties |

| Mechanical Properties | Compressive, tensile, flexural strength, abrasion resistance | Often higher strength due to firing and shaping |

| Operational Properties | Thermal shock, slag, acid/alkaline, oxidation, hydration resistance | Performance varies by material and shape |

Refractory castables are easy to use and can make one solid layer. They stick well, bounce back, and get hard. These features help them work in kilns with very high heat.

Refractory castables are used in many jobs that need heat protection. Workers use them to cover kilns and furnaces in metal, chemical, power, and steel factories. Castables can be poured or shaped into tough forms. This makes them good for sealing, tube holes, and lining spots outside the main furnace. Some types, like steel fiber reinforced, acid-resistant, and insulating castables, are made for special jobs in rough places.

Common uses include:

Lining kilns and furnaces in factories

Making shapes to fix or replace broken parts

Giving insulation to keep heat in machines

Stopping damage from hot metals, slag, and gases

These jobs need castables that can take high heat, handle quick temperature changes, fight chemicals, and stay strong. Castables must not break or crack, even when the kiln gets hot or cools down fast.

Refractory cement is a special cement for very high heat. Experts look at what chemicals are in it. Most types have low-calcium aluminate cement. This kind has about 70% alumina and 19-23% calcium oxide. Some types have calcium magnesium aluminate cement. These have 66-74% alumina, 13-18% calcium oxide, and 10-13% magnesium oxide. Refractory cement can handle heat above 1650 °C. It stays strong and does not get damaged by chemicals. The cement must be very fine, with a surface area over 300 m²/kg. It should not set too fast or too slow. This helps workers mix and use it easily. To make refractory cement, people heat fireclay, silica, and magnesia. They heat these materials to 1500-1550 °C. This makes the cement tough against melting and breaking. It also helps the cement stay strong in kilns and other hot places.

Refractory cement has many features that help it work in hot places. It keeps its shape and strength in high heat. The cement does not melt or break down easily. It fights off damage from hot gases and liquids. The cement does not crack or shrink much when heated. Its tiny particles help it stick to other things. The cement sets in a certain amount of time. This lets workers shape it before it gets hard. These features help protect kilns and furnaces from harm. The cement also keeps heat inside, making factories safer and saving energy.

| Property | Description |

|---|---|

| High Temperature Resistance | Handles heat above 1650 °C |

| Chemical Stability | Fights damage from hot gases and melted stuff |

| Volume Stability | Keeps its shape and size when heated and cooled |

| Setting Time | Starts to set after 45 minutes, finishes by 390 minutes |

| Fine Texture | Has a surface area over 300 m²/kg for better sticking |

Tip: Refractory cement must follow strict rules to work well in hot, tough places.

Refractory cement is used in many jobs that need heat protection. Workers mix it and pour it into forms to make shapes. This makes it easy to fix or build new linings in kilns and furnaces. Steel mills, glass factories, and ceramic plants use this cement a lot. It lines rotary kilns, clinker coolers, and preheaters in cement plants. The cement also protects boilers, incinerators, and chimneys from fire and chemicals. In foundries and forging shops, it makes a strong liner that regular mortar cannot do. Power plants and chemical factories use it to protect equipment from heat and chemicals. The cement helps keep workers safe and makes repairs faster and better.

Typical uses include:

Lining and fixing kilns and furnaces

Protecting boilers and incinerators from heat and chemicals

Making special shapes for furnace building

Giving fireproofing and heat protection in steel, glass, and ceramic factories

Shielding chimneys and fireplaces in big buildings

Refractory cement is important for keeping hot equipment safe and working well. Its special features help factories build strong and lasting structures.

Refractory castable and refractory cement are made differently. Refractory cement is a binder. It has high-alumina calcium aluminate, doloma-magnesia, or phosphate-bonded systems. These cements have 50% to 80% alumina. They set by chemical bonding or hydration. Refractory castable uses only a little cement as a binder. Most of it is made from aggregates like calcined bauxite. Castables also have additives like water reducers and anti-shrink agents. The table below shows the main differences in what they are made of:

| Aspect | Refractory Castable | Refractory Cement |

|---|---|---|

| Aggregates | Present (60–70%, e.g., calcined bauxite) | Absent (pure binder) |

| Binder | Partial (8–15%, calcium aluminate, etc.) | Entirely binder (100%, calcium aluminate/silicate) |

| Additives | Included (dispersants, anti-shrink agents) | Minimal or none (set modifiers) |

| Particle Size | Multi-grade (0–10 mm aggregates + fines) | Ultrafine powder (<200 mesh) |

Low cement refractory castables swap some cement for ultra-fine powders. This makes them stronger and less porous. These castables can have as little as 1% cement. The rest is alumina, silica, and other minerals. This mix gives castables their special features.

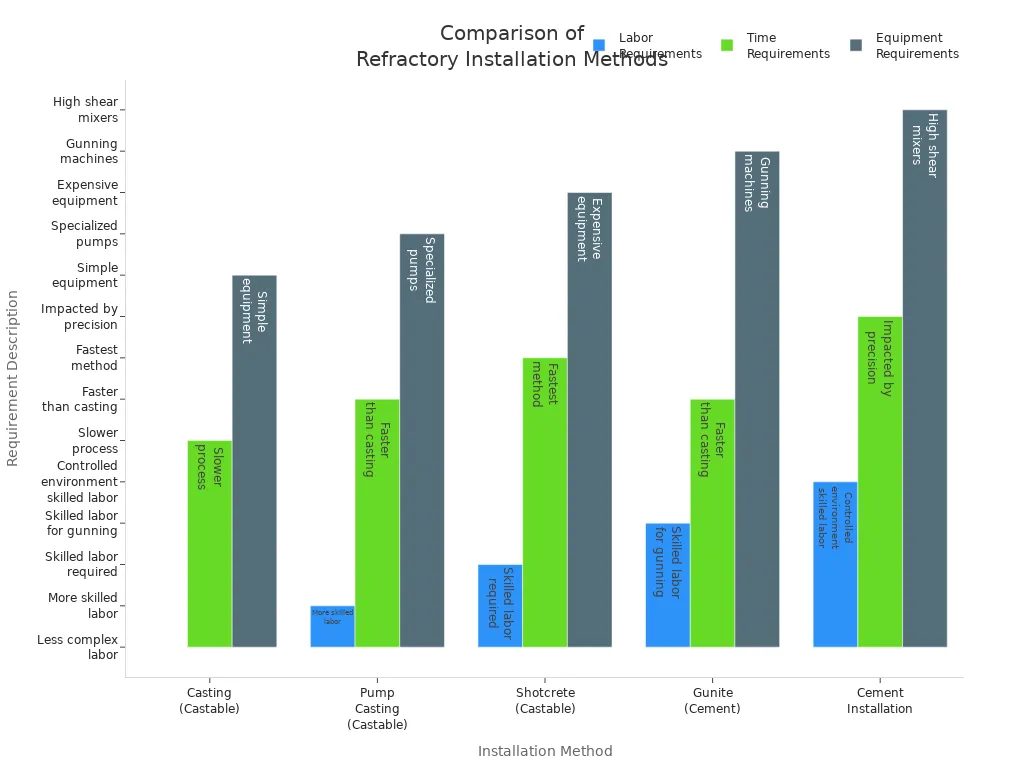

How workers install refractory castable and refractory cement is also different. To use refractory castable, workers mix it with water. Then they pour it into molds or formwork. This can take a long time if done by hand. For big jobs, workers use pump casting or shotcrete. These need skilled workers and special machines. Pump casting uses pumps. Shotcrete sprays the material fast. These ways are quicker but cost more and need trained people.

Refractory cement needs more care. Workers must watch water quality and mixing. They use high shear mixers and keep the area controlled. This stops the cement from setting too soon. Gunning sprays the cement with a machine. This is faster than casting but needs skilled workers. The table below compares the main ways to install them:

| Installation Method | Labor Requirements | Time Requirements | Equipment Requirements |

|---|---|---|---|

| Casting (Refractory Castable) | Less complex labor, generally slower process | Slower due to manual mixing and pouring | Simple equipment; waterproof formwork needed |

| Pump Casting (Refractory Castable) | More skilled labor due to equipment operation | Faster than casting, suitable for large volumes | Specialized, expensive pneumatic or piston pumps |

| Shotcrete (Refractory Castable) | Skilled labor required for machine operation | Fastest method, can apply 5+ tons per hour | Expensive piston pump and air equipment |

| Gunite (Dry Mix, Refractory Cement) | Skilled labor for gunning machine operation | Faster than casting but slightly lower refractory properties | Specific gunning machines, relatively inexpensive |

| Refractory Cement Installation | Sensitive to water quality and mixing conditions; requires controlled environment and skilled labor | Time impacted by mixing precision and environmental controls | High shear mixers, air-conditioned or temperature-controlled facilities |

Castables need careful mixing and vibration to get rid of air bubbles. Workers cure the lining for up to 72 hours. Cement sets faster but needs careful control to stop cracks or weak spots.

Refractory castable and refractory cement work differently in high heat. Castables with low or ultra-low cement are very strong and resist heat well. They keep their shape and strength even at 1700°C. Fine powders and additives help make strong bonds. This helps them fight heat, wear, and chemicals.

Refractory cement, even high-alumina types, starts strong but can get weaker at 800°C to 1100°C. This happens when the binder loses water and changes. Additives like silica help, but cement-bonded castables still have limits in high heat. The table below shows key performance differences:

| Performance Metric | Refractory Castable (Low/Ultra-Low Cement) | Refractory Castable (High Cement Content) |

|---|---|---|

| Cement Content | ≤ 2 wt% (LCC), ≤ 1 wt% (ULCC) | > 2 wt% |

| Microstructure | Fine, homogeneous grains and pores; mullite bonding dominates | Increased liquid phases; coarse pores; mullite bonds disrupted |

| Thermal Resistance | High; maximum working temperature (T0.5) stable with cement ≤ 2% | Decreased due to liquid phase formation and pore coarsening |

| Mechanical Strength (Hot) | Enhanced, especially with additives like reactive alumina | Degraded due to rapid deformation under thermo-mechanical loads |

| Flowability | Reduced in ultra-low cement castables | Better flowability |

| Overall Performance | Superior high-temperature performance and mechanical strength | Inferior thermo-mechanical properties at elevated temperatures |

Regular refractory cement can take heat up to 1600°C. It sticks well and is strong. But it may crack or get weak after many heating and cooling cycles. Castables with less cement do better with these problems. They also handle sudden heat changes and chemicals well. In steel plants, using good castables or cement can cut downtime and make things safer.

Note: Picking the right material can stop cracks, lower repairs, and keep workers safe in hot places.

Choosing between refractory castable and refractory cement depends on the job. Castables are best for tricky shapes, big linings, and places with lots of heat or stress. Workers use them in kilns, furnaces, preheaters, and coolers. Castables can be poured or sprayed, so they are good for repairs and new builds.

Refractory cement is best for sticking bricks, fixing small cracks, or making thin linings. It sets fast and is good for small repairs. Sometimes, high-temperature cement lines furnaces or boilers, but it may not last as long as castable in tough spots.

The table below gives real examples:

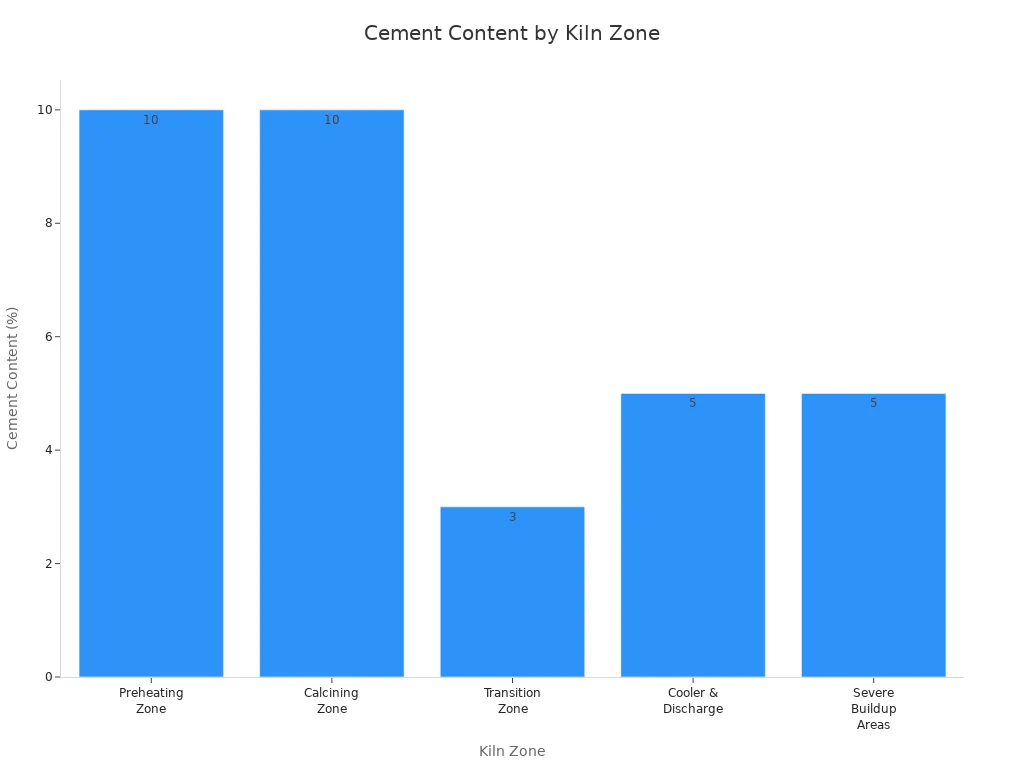

| Kiln Zone | Conditions & Requirements | Refractory Castable Type | Properties & Applications |

|---|---|---|---|

| Preheating Zone | Moderate temp (600–900°C), alkali exposure, abrasion | Low Cement Castables (LCC) | High density, thermal shock & abrasion resistance; used in preheaters and coolers; cement <10%, Al₂O₃ 60–85% |

| Calcining Zone | High abrasion, moderate thermal load | Low Cement Castables (LCC) | Good abrasion resistance; Al₂O₃ 60–70% |

| Transition Zone | Frequent thermal fluctuations, chemical attacks | Ultra-Low Cement Castables (ULCC) | Very low porosity, high strength, excellent thermal shock & alkali resistance; cement <3%, Al₂O₃ 70–90% |

| Cooler & Discharge | High mechanical abrasion, moderate thermal load | Self-Flowing Castables | Easy to install in complex shapes; high mechanical strength; cement <5%, Al₂O₃ 60–80% |

| Severe Buildup Areas | Areas with buildup issues (e.g., preheater, cooler) | Silicon Carbide Containing Castables | Non-sticking properties to reduce buildup; not recommended with water blasting due to oxidation risk |

For example, a steel mill changed its furnace lining to high-temperature refractory cement. This cut maintenance by 30% and saved 20% energy. The cement kept heat in and stayed stable. In other cases, using pure, pre-shrunk insulating castables stopped cracks and made things safer. Picking the right refractory material can help things work better and cost less.

Tip: For tricky shapes, quick repairs, or places with lots of wear, pick refractory castable. For small fixes or sticking bricks, use refractory cement.

Picking the right refractory material for hot jobs needs careful thought. Each type—refractory castable, refractory cement, and refractory brick—has good points and some limits. The best choice depends on what the job needs, where it is, and how long it should last.

Experts say you should first know the temperature range. Refractory bricks like those from Yufeng Refractory work well from 1400°C to 1750°C. Alumina-based refractory castables can take even higher heat, up to 1800°C. The working temperature must stay below the highest temperature the material can handle.

Chemical compatibility is very important. Some places have acids, alkalis, slag, or bad gases. High alumina bricks fight off acid damage. Magnesia-carbon bricks do well in basic places with slag. Castables can get special additives to help them resist chemicals, so they work in tough spots.

Mechanical stress matters too. Things like abrasion, impact, and thermal shock affect what you pick. Refractory bricks are strong against abrasion and stay stable when heated and cooled. Castables have higher crushing strength, from 30 to 100 MPa. Bricks are usually 20 to 60 MPa. Castables make smooth linings, so there are fewer cracks and less heat loss.

How you build with the material is also important. Castables can be poured, vibrated, or sprayed into tricky shapes. This makes them great for rotary kiln tires, cyclones, and quick fixes. Bricks need cutting and mortar, which works for simple shapes and places that need lots of abrasion resistance.

Cost and speed matter for many jobs. Castables usually cost less per ton and are faster to install. They let workers use machines to build furnaces, saving time and work. Bricks cost more and take longer to put in, but last longer if set with good mortar.

Rules about the environment and safety also affect the choice. Factories must follow rules about emissions, waste, and saving resources. Strong, high-quality refractories that meet these rules are best. Safety steps like dust removal and protective gear keep workers safe during setup and repairs.

New technology has brought low-cement and ultra-low-cement castables. These use microsilica and tiny additives to lower porosity and boost strength. Moving from regular castables to cement-free types has made them work better at high heat and become denser. Nanotechnology makes them stronger, more flexible, and better at fighting heat shock and chemical damage.

The table below shows key technical factors for comparing materials:

| Parameter | Refractory Castables | Refractory Bricks (Firebricks) |

|---|---|---|

| Maximum Service Temp | 1600–1800°C (alumina-based) | 1400–1750°C (high alumina) |

| Mechanical Strength | Higher cold crushing strength (30–100 MPa) | Moderate strength (20–60 MPa) |

| Thermal Conductivity | Lower to moderate (1.0–2.5 W/m·K) | Moderate to higher (1.5–3.5 W/m·K) |

| Abrasion Resistance | Moderate, can be improved with additives | High due to dense structure |

| Lifespan | 5–8 years (sensitive to curing) | 7–15 years (with quality bricks/mortar) |

Other things to think about include:

Composition and particle size: Changing the mix of big and small particles changes how the material works.

Binder type and amount: Calcium aluminate cement and other binders change how fast it sets and how strong it is.

Thermal stability: Materials must handle quick temperature changes without breaking.

Bulk density: Lower density means less heat stored and less energy used.

Electrical conductivity: Insulating materials are needed for electric furnace linings.

Maintenance requirements: Castables are easier and quicker to fix, sometimes even while the kiln is running. Bricks need more time to fix.

Factories must watch emissions, control dust, and use good practices to follow environmental rules. More factories now pick eco-friendly refractories, including ones made from recycled stuff, to meet these standards.

Experts say you should talk to skilled contractors for the best refractory design and setup. Regular checks and repairs help things last longer. The choice between refractory castable, refractory cement, and refractory bricks should balance job needs, shape complexity, abrasion, heat cycles, chemical exposure, speed, and cost.

Real-life examples show how different industries pick refractory materials for their own problems. Here are some cases:

In a cement kiln transition zone, engineers changed from firebricks to phosphate-bonded castables. The new lining lasted 40% longer and cut downtime. Castables gave smooth insulation and fought off chemical damage from kiln gases.

A steel reheating furnace hearth had bad slag corrosion. Magnesia-carbon bricks replaced alumina castables, making the lining last three times longer. The bricks’ dense structure gave better wear resistance and stayed stable.

Coal-fired power plants use silicon carbide refractories in ash hoppers and high alumina bricks in burning zones. These choices make the lining last 30% longer than fireclay bricks.

Waste-to-energy boilers face harsh flue gases like HCl and SO₂. Zirconia-enhanced castables with acid-resistant coatings cut repair time and kept performance strong in tough conditions.

The table below shows case studies from different industries:

| Industry/Application | Challenge | Refractory Solution | Outcome |

|---|---|---|---|

| Cement Kiln Transition Zone | Chemical attack, thermal cycling | Phosphate-bonded castables | 40% longer campaign life, reduced downtime |

| Steel Reheating Furnace Hearth | Slag corrosion | Magnesia-carbon bricks | Tripled lining lifespan |

| Coal-Fired Power Plant Boiler | High ash content, 1500°C temps | Silicon carbide refractories, high alumina bricks | 30% longer lifespan than fireclay |

| Waste-to-Energy Boiler | Corrosive flue gases | Zirconia-enhanced castables, acid-resistant coatings | Reduced downtime for repairs |

How you install and the cost also matter. Castables need mixing and careful curing, which takes 24 to 72 hours. Bricks need cutting and mortar, usually done in 12 to 24 hours. Castables cost less per ton and have medium labor costs. Bricks cost more but need less labor to install.

| Aspect | Castables | Refractory Bricks |

|---|---|---|

| Installation Workflow | Mixing, curing (24–72 hrs) | Cutting, mortar setting (12–24 hrs) |

| Material Cost | $800–$1,500/ton | $1,200–$2,000/ton |

| Labor Cost | $300–$600 | $200–$400 |

Durability and maintenance are different for each type. Castables can be shaped into one piece, making them last 30% to 150% longer. Their smooth structure keeps air out and stops heat loss. Maintenance is easier and faster, sometimes even while the kiln runs. Bricks are better at handling slow changes and wear, so people pick them for top-quality jobs. But fixing bricks is harder and takes more time.

New refractory technology keeps changing how materials are picked. Low-cement and ultra-low-cement castables use microsilica and tiny additives to lower porosity and boost strength. These new types help castables work better in tough places like steel and glass factories. Nanotechnology makes them stronger, more flexible, and better at fighting heat shock and chemical damage. Factories get better bonding and crack control, and someday these materials may even fix themselves.

Rules about the environment and safety make factories pick strong, long-lasting refractories. Factories must control emissions, waste, and how they use resources. Safety risks like dust and burns mean workers need gear, dust removal systems, and strict safety rules. Watching air quality and stopping dust helps meet health standards.

Experts say it’s important to match refractory materials to the exact hot job. They suggest checking temperature range, chemical resistance, mechanical stress, building method, heat flow, and cost. Talking to specialists helps get the right design and setup, stopping early failure and making equipment last longer.

Tip: Always pick the refractory material that fits the job, follows rules, and keeps workers safe. Ask experts for hard jobs and keep learning about new technology.

The table below shows the main differences between refractory cement, refractory castable, and refractory brick. Fire brick is shaped and has strong bonds. This makes it great for lining furnaces and kilns. Fire brick can take high heat, sudden temperature changes, and chemical damage. Refractory castable is easy to install and makes smooth linings. Refractory cement hardens fast and sticks things together well. Picking the right fire brick or castable keeps things safe, strong, and saves energy. Use this checklist to help you choose:

| Material Type | Composition | Application | Features |

|---|---|---|---|

| Refractory Cement | Aluminate clinker | Binder, high-temp linings | Fast hardening, strong bonding |

| Refractory Castable | Aggregates, binders | Integral kiln lining | Seamless, flexible |

| Refractory Brick | Shaped, bonded by mortar | Furnace, kiln lining | High strength, durability |

Quick Checklist:

Pick fire brick or castable for the right temperature.

Make sure it can handle chemicals and is strong.

Check how it is put in and how to fix it.

Look at the maker’s info and safety sheets.

Refractory brick is used to line furnaces, kilns, and fireplaces. It keeps equipment safe from high heat and chemicals. Many factories use it to help machines last longer.

Sometimes, refractory castable can take the place of refractory brick. Castable is good for tricky shapes or fast fixes. Refractory brick is stronger and lasts longer where there is a lot of wear.

Refractory cement can handle much higher heat than regular cement. It has special minerals like alumina inside. Regular cement cannot stand up to the heat in kilns or furnaces.

A refractory brick lining can last from 7 to 15 years if cared for. How long it lasts depends on heat, chemicals, and how it is kept up. Good bricks from trusted companies like Yufeng Refractory last even longer.

Yes, it is safe to use refractory brick in pizza ovens. It holds heat well and does not break easily. Many people pick refractory brick for even cooking and long use in home and restaurant ovens.