Views: 0 Author: Site Editor Publish Time: 2025-08-17 Origin: Site

Zirconia ceramics are a type of refractory ceramics. They can handle very high heat. These materials are very strong and tough. They also do not get damaged by chemicals easily. Scientists say zirconia is special because of phase transformation toughening. This helps stop cracks and makes it last longer. The world market for zirconia ceramics has grown fast. This is because people need them in dentistry, biomaterials, and factories. Makers often pick zirconia for jobs that need to work well in hard conditions.

Zirconia ceramics are very strong and can handle heat. They work where other materials cannot. They do not break down from chemicals. They stop cracks from getting bigger, so they last longer. Many industries use zirconia for hard jobs. These jobs include dental implants, engine parts, and electronics. New ways to make zirconia, like 3D printing, help a lot. These ways make parts more exact and better for the environment. Zirconia ceramics help save energy and cut down on waste. They also make products last longer.

Zirconia ceramics are part of refractory ceramics. They can handle very high heat and tough places. People use them when they need something that does not melt or break. These ceramics do not react with chemicals easily. Zirconia ceramics are a kind of oxide refractory. This means they are mostly made from metal oxides. Factories use zirconia ceramics where other materials cannot work because of heat or quick temperature changes.

Note: Refractory ceramics include things like bricks and shapes. Zirconia ceramics are special refractory products. They may look rough and have holes, but they work well in hard conditions.

Here are some facts about zirconia ceramics and refractory ceramics:

Refractory ceramics are not metal and not organic.

They can stand high heat and chemicals.

Zirconia ceramics are oxide refractories.

They are used where heat changes fast.

Zirconia crucibles are a good example of specialty refractory products.

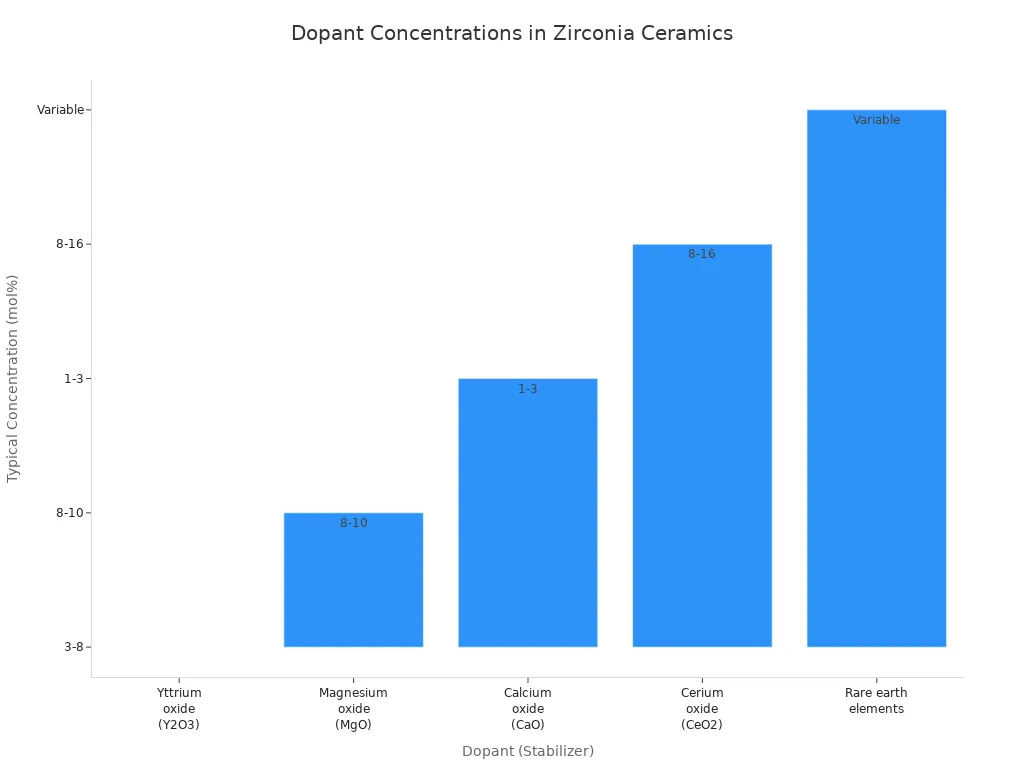

Zirconia ceramics are mostly made from zirconium dioxide (ZrO₂). This makes them strong and hard to wear out. Makers add small amounts of other oxides to make them better. These are called dopants or stabilizers. The most common ones are yttrium oxide (Y₂O₃), magnesium oxide (MgO), calcium oxide (CaO), and cerium oxide (CeO₂). These help keep the crystal shape steady when it gets hot and make them tougher.

| Zirconia Type | Zirconium Dioxide (ZrO₂) Content |

|---|---|

| Standard Zirconia | About 95% |

| Toughened Zirconia | About 85% |

Makers pick the type and amount of dopant for what they need. For example, yttrium-stabilized zirconia (YSZ) is used in factories and medicine. Each dopant helps in a special way:

| Dopant (Stabilizer) | Typical Concentration | Main Effects on Performance |

|---|---|---|

| Yttrium oxide (Y₂O₃) | 3-8 mol% | Makes it tougher, stronger, and helps ions move |

| Magnesium oxide (MgO) | 8-10 mol% | Helps with heat shock and makes it stronger |

| Calcium oxide (CaO) | 1-3 mol% | Keeps it steady at high heat |

| Cerium oxide (CeO₂) | 8-16 mol% | Makes it tougher and stronger, keeps cubic phase |

| Rare earth elements | Variable | Changes how well it conducts and keeps phases steady |

Other things like copper, cobalt, iron, manganese, and zinc can be added. These help lower the heat needed to make the ceramic and control grain size. The right mix of zirconium dioxide and dopants gives zirconia ceramics their famous strength, toughness, and ability to stand heat and chemicals.

Zirconia is different from other refractory ceramics. It has a mix of special properties. These make it great for tough jobs where other materials might not work. Knowing these features helps us see why zirconia is used in many fields. People use it for things like ceramic refractory bricks and electronics.

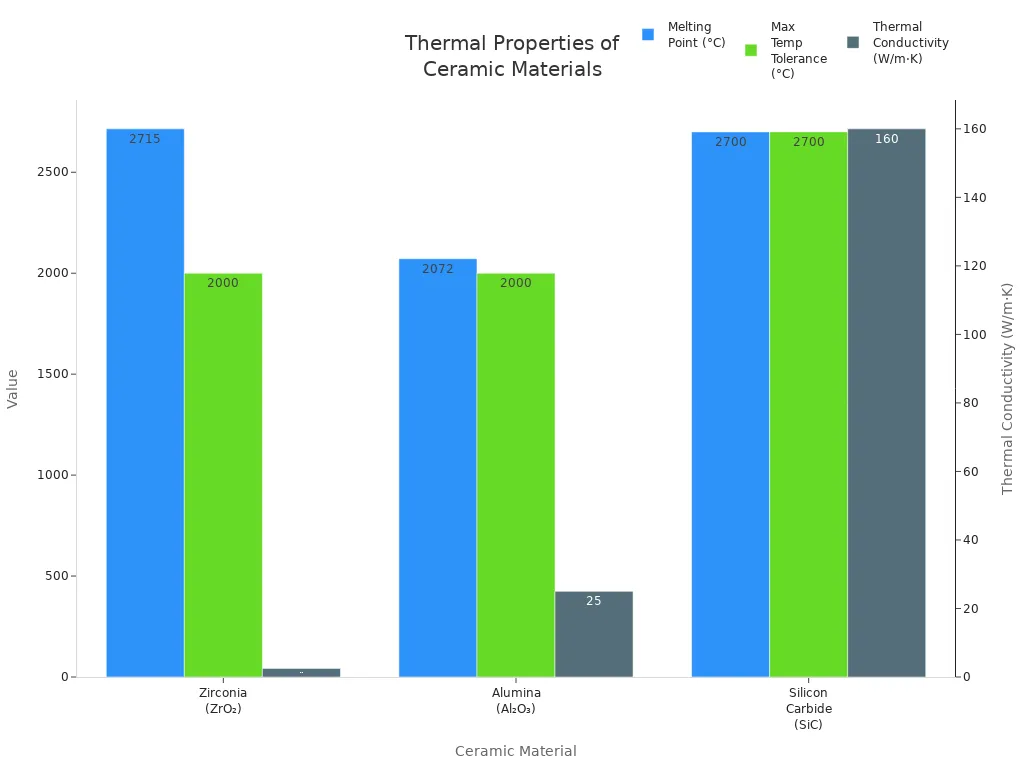

Thermal stability means a material keeps its shape and strength in high heat. Zirconia ceramics are very good at this. They can handle heat that would melt or ruin other materials. Zirconia melts at about 2715°C. This is higher than most other refractory ceramics. That is why zirconia is a good pick for places with extreme heat.

| Zirconia Ceramic Type | Maximum Temperature Before Structural Degradation | Notes on Degradation Behavior |

|---|---|---|

| Yttria-Stabilized Zirconia (YTZP) | ~500°C (932°F) | Strength and toughness degrade above this; rapid degradation in water vapor at 200-300°C |

| Zirconia Toughened Alumina (ZTA) | ~1500°C (2732°F) | Strength contribution reduces above this temperature |

A study showed yttria-stabilized zirconia coatings stay strong up to 1250°C for 48 hours. Some small changes happen inside, but it does not break. This means zirconia works well in hot places like kilns and furnaces. Other refractory ceramics might fail there.

Zirconia lets less heat pass through than other ceramic refractory bricks. It is a great insulator. For example, alumina lets 20-30 W/m·K of heat through. Zirconia only lets 2-3 W/m·K through. Silicon carbide lets even more heat through, up to 200 W/m·K. Because of this, zirconia is used in thermal barrier coatings to protect equipment from heat.

| Ceramic Material | Melting Point (°C) | Maximum Temperature Tolerance (°C) | Thermal Conductivity (W/m·K) | Thermal Shock Resistance | Notes |

|---|---|---|---|---|---|

| Zirconia (ZrO₂) | ~2715 | >2000 | 2-3 | Moderate (phase stability temperature-dependent) | Superior thermal stability at ultra-high temperatures; suitable for thermal barrier coatings but brittle |

| Alumina (Al₂O₃) | ~2072 | ~1600-2072 | 20-30 | Weak | Cost-effective; less thermally stable and weaker thermal shock resistance |

| Silicon Carbide (SiC) | ~2700 | Up to 2700 | 120-200 | Excellent | High thermal conductivity and shock resistance; ideal for heat dissipation and high-temperature applications |

Tip: Zirconia’s low thermal conductivity keeps heat inside furnaces. This saves energy and protects equipment.

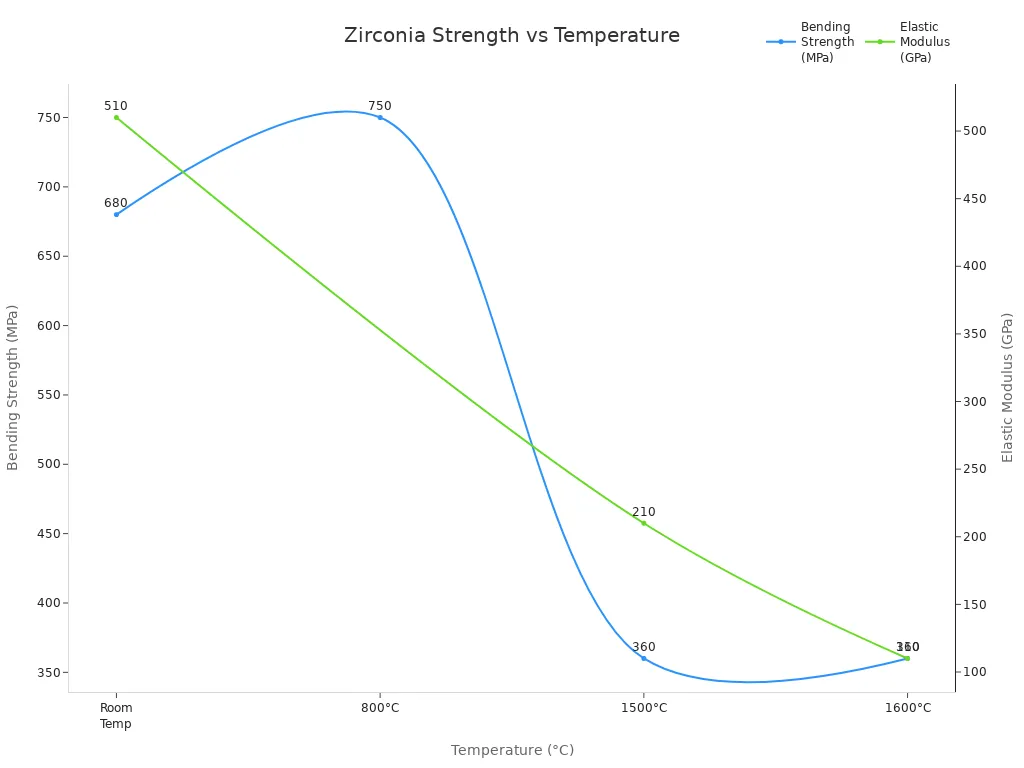

Mechanical strength tells us how much force a material can take before breaking. Zirconia ceramics have very high flexural strength. They can reach up to 1000 MPa. This is much higher than many other refractory ceramics. The fracture toughness is also high. It measures how well a material stops cracks. Zirconia usually has values from 7 to 10 MPa·m^0.5. This means zirconia can handle heavy loads and does not break easily. It works well even in thin shapes or as ceramic refractory bricks.

| Property | Typical Value |

|---|---|

| Fracture Toughness | 7–10 MPa·m^0.5 |

| Flexural Strength | Up to 1000 MPa |

Zirconia’s mechanical strength changes with temperature. At room temperature, it has a bending strength of about 680 MPa and an elastic modulus of 510 GPa. At 700°C, the strength stays almost the same. At 800°C, the strength can go up a little. But above 1000°C, the strength starts to drop. At 1500°C, the bending strength falls to about 360 MPa. This happens because the inside structure changes and gets weaker.

| Temperature (°C) | Bending Strength (MPa) | Elastic Modulus (GPa) | Fracture Toughness (MPa·m½) | Notes |

|---|---|---|---|---|

| Room Temperature | 680 | 510 | 3.6 | Baseline mechanical properties |

| 700 | Nearly unchanged | Decreasing linearly | Not specified | Strength stable up to this temperature |

| 800 | 750 | Not specified | 4.8 | Slight increase in strength and toughness |

| 1000 | Decreasing | Not specified | Not specified | Strength controlled by SiC cluster size |

| 1200+ | Significant decrease | Not specified | Not specified | Oxidative damage and microstructural changes reduce strength |

| 1500 | ~360 | 210 | 3.3 | Large drop in strength and modulus |

| 1600 | ~360 | 110 | 3.3 | Further decrease; microstructure and impurities affect properties |

Note: The best mechanical strength comes from careful making. The sintering temperature must be just right. Too much heat makes the grains inside grow too big. This weakens the ceramic.

Chemical resistance means a material does not react with acids, bases, or other chemicals. Zirconia ceramics are very good at this. They do not corrode or break down in most harsh places. This makes them great for chemical plants, labs, and even in the body as dental implants or joints.

Zirconia is mostly inert. This means it does not react with most chemicals. It is also biocompatible, so it works well inside the body. But there are limits. In very tough places, like inside the body or in strong acids, zirconia can still corrode. Some companies add special coatings to help. But these coatings may not last forever. Over time, harsh conditions can wear them away.

Alert: Zirconia resists many chemicals, but not all. For the hardest jobs, engineers might need extra protection or a different refractory ceramic.

Thermal shock resistance shows how well a material handles quick temperature changes. Many refractory ceramics crack when heated and cooled fast. Zirconia ceramics do better because of transformation toughening. When a crack starts, the inside structure changes. This stops the crack from growing. Zirconia is much tougher and less likely to break from thermal shock.

Zirconia composites, like alumina–mullite–zirconia, keep about half their strength after many heating and cooling cycles. This is better than pure alumina or mullite. Transformation toughening and high fracture toughness help zirconia stop cracks. Engineers add other materials, like mullite or rare earth elements, to make this property even better.

Transformation toughening through phase change increases fracture toughness and stops cracks.

Moderate thermal expansion and toughening mechanisms reduce thermal stress.

Adding second phases with low thermal expansion, like mullite or alumina, improves toughness.

Rare earth stabilizers, such as yttrium oxide, keep the structure stable and prevent harmful changes.

Microstructural changes, like forming mullite whiskers, help stop cracks from spreading.

Tip: Zirconia’s thermal shock resistance makes it a top pick for ceramic refractory bricks in furnaces, kilns, and other places with quick temperature changes.

Zirconia ceramics are important in many industries. Factories use them because they are strong and hard to wear out. Aerospace companies put zirconia on turbine blades and heat shields. Car makers use zirconia for engine parts that get hot or face a lot of force. Foundries use zirconia in pump seals, piston rings, bearing balls, and grinding tools. These parts must work in tough places and handle lots of rubbing.

Zirconia ceramics work better than other refractory ceramics in foundries. Their tensile strength is about 330 MPa, which is higher than alumina. Zirconia does not let much heat pass through, only 2-3 W/mK. This makes it a good thermal barrier. It also does not react with acids or alkalis. Zirconia is heavy, between 5.68 and 6.05 g/cm³, so it handles pressure well. Its smooth surface (Ra0.02) helps parts move easily and lowers friction.

| Property/Benefit | Zirconia Ceramic Advantage |

|---|---|

| Mechanical Strength | Tensile strength (~330 MPa), high modulus of rupture |

| Wear Resistance | Low friction, excellent durability |

| Thermal Properties | Low thermal conductivity, superior thermal shock resistance |

| Chemical Stability | Corrosion resistance to acids and alkalis |

| Density | High density, better compression performance |

| Surface Finish | Superior finish, less friction |

| Application Examples | Pump and valve seals, piston rings, bearing balls, grinding media |

Industries like aerospace, cars, electronics, and factories use zirconia ceramics. They need materials that can take heavy loads, not crack, and handle quick heat changes. Zirconia ceramics do this better than most other refractory ceramics.

Tip: Zirconia ceramics help factories save money and time. They last longer and work well in hard jobs.

Doctors and dentists use zirconia ceramics for teeth and bone repairs. Dentists pick zirconia for crowns, bridges, posts, and implants. Surgeons use zirconia for hip and knee joints, tools, and fake body parts. Zirconia is tough and does not wear out fast, so it is good for body parts that carry weight.

Zirconia ceramics are safe for the body. People who are allergic to metal can use zirconia implants. Zirconia looks like a real tooth, so it looks nice, even if gums are thin. Tests show zirconia dental parts have flexural strength from 900 to 1200 MPa. These parts last a long time and do not chip or wear down easily.

Dental crowns and bridges made from zirconia ceramics look real and last longer than metal ones.

Hip and knee joints use zirconia toughened alumina for better wear and strength.

Surgical tools made from zirconia ceramics stay sharp and do not rust.

Note: Zirconia ceramics are safe and strong for medical tools and implants. They help patients heal better.

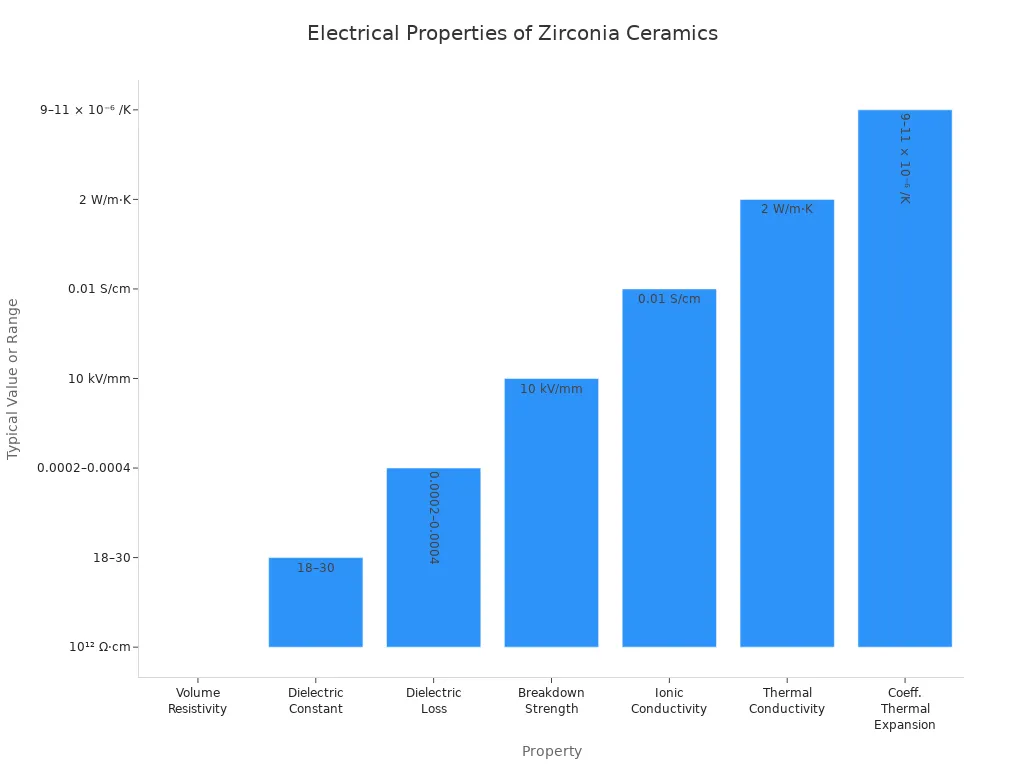

Zirconia ceramics are used in many electronic devices. Engineers use zirconia in oxygen sensors, fuel cells, circuit boards, and heaters. Car makers put zirconia oxygen sensors in exhaust systems to check gases and help engines run better. These sensors have a zirconium dioxide part with platinum on it. At high heat, zirconia lets oxygen ions move, so the sensor can measure oxygen levels.

Zirconia ceramics are also used as bases for microchips, radio devices, and sensor covers. Their electrical features make them great for important electronics. Zirconia has volume resistivity over 10¹² Ω·cm, so it is a good insulator. The dielectric constant is between 18 and 30, which helps in circuits. Dielectric loss is low, so signals do not get lost. Breakdown strength is over 10 kV/mm, so it works safely at high voltage.

| Electrical Property | Typical Value or Range | Relevance to Electronic Applications |

|---|---|---|

| Volume Resistivity | >10¹² Ω·cm | Prevents current leakage |

| Dielectric Constant (εr) | 18–30 | Stable insulating behavior |

| Dielectric Loss (tan δ) | 0.0002–0.0004 | Minimizes signal loss |

| Breakdown Strength | >10 kV/mm | Reliable under high voltage |

| Ionic Conductivity (YSZ) | 0.01 S/cm at 1000 °C | Enables fuel cells and sensors |

| Thermal Conductivity | ~2 W/m·K | Protects sensitive electronic parts |

| Coefficient of Thermal Expansion | 9–11 × 10⁻⁶ /K | Matches semiconductor packaging |

Zirconia ceramics are also used in 5G antennas, fingerprint sensors, and heating elements. They insulate and resist heat, so they are needed for modern electronics.

Alert: Zirconia ceramics help electronics work safely and well, even in tough places.

Many everyday products use zirconia ceramics for their special features. Makers use zirconia in scissors, knives, slitters, pump shafts, tools, tweezers, wire rings, bearing sleeves, and valves. These items need to be hard, not wear out, and not react with chemicals.

| Consumer Products Incorporating Zirconia Ceramics | Advantages Provided by Zirconia Ceramics |

|---|---|

| Scissors, knives, slitters | High hardness, wear resistance |

| Pump shafts, metal-forming tools, fixtures | High strength, chemical resistance |

| Tweezers, wire drawing rings, bearing sleeves | Acid and alkali corrosion resistance |

| Valves | High temperature resistance |

| Electrical insulation | |

| Mechanical strength | |

| Low density | |

| Resistance to thermal shock | |

| Food safety |

Zirconia ceramics make these products last longer and work better. Kitchen knives made from zirconia stay sharp and do not rust. Tweezers and wire rings keep their shape and do not get damaged by acids. Valves and pump shafts made from zirconia can take high heat and force.

Zirconia ceramics are also used in electronics for things like fingerprint sensors. Their high dielectric constant and non-metallic nature help in making new electronic parts.

Tip: Products with zirconia ceramics last longer, work better, and are safer for people to use.

Factories now use new ways to make zirconia refractory ceramics. These methods help them make better ceramic refractory bricks and other materials. Additive manufacturing, like stereolithography (SLA) and direct light processing (DLP), builds zirconia parts layer by layer. This uses less material and less energy than older methods. It also lets factories make shapes that were hard before. But sometimes, the layers have weak spots. Workers must be careful so cracks do not form.

Microwave sintering heats zirconia with electromagnetic waves. This process is much faster than old sintering. It can be up to six times quicker. It saves energy and gives more even heat. But it can make the ceramic less see-through. Hot-isostatic pressing (HIP) after sintering makes the ceramic tougher and denser. Some companies use special CAD/CAM blocks with layers of different zirconia types. These blocks balance strength and see-through quality for teeth and machines.

| Manufacturing Advance | Description | Benefits | Limitations / Notes |

|---|---|---|---|

| Additive Manufacturing (AM) | Builds parts layer by layer with photosensitive zirconia slurries. | Less waste, complex shapes, saves energy. | Weaker joins between layers, needs careful work. |

| Microwave Sintering | Heats with electromagnetic energy. | Faster, uses less energy, even heat. | Can lower see-through quality. |

| Hot-Isostatic Pressing (HIP) | Uses high pressure and heat after sintering. | Makes ceramic tougher and denser. | Small improvement for some dental ceramics. |

| Composition-gradient CAD/CAM | Blocks with layers of different zirconia types. | Balances strength and see-through quality. | Layer flaws can weaken the ceramic if not controlled. |

Additive manufacturing helps make custom dental implants and bone scaffolds. These new ways let engineers control how many holes and how strong the ceramic is for special jobs.

Making refractory ceramics uses lots of energy and chemicals. This can hurt the environment. Companies now try to make zirconia ceramic production greener. They use energy-saving ways, like low-temperature synthesis and microwave sintering. Some factories recycle zirconia waste from making steel or dental parts. They turn this waste into new ceramic tiles or jewelry. This saves raw materials and cuts down on landfill waste.

Factories reuse zirconia to lower the need for new mining.

Companies like Kyocera and Saint-Gobain use eco-friendly coatings and life cycle checks.

Some use solar or wind power to lower greenhouse gas emissions.

Safer, water-based coatings replace toxic chemicals. This makes work safer for people and the planet.

Packaging now uses recycled or biodegradable materials to cut waste.

Sustainable mining, like planting trees and saving water, helps protect nature.

♻️ Recycling zirconia waste saves money and helps the environment by lowering hazardous waste.

Zirconia refractory ceramics are now used in new technology. Electronics makers use them in sensors and solid oxide fuel cells. These help make cleaner energy. Nanostructured zirconia ceramics are tougher and resist wear better. This makes them good for aerospace and medical implants. Jewelry makers use colored, see-through zirconia for fancy products.

Researchers make zirconia nanocomposites with carbon nanotubes and graphene. These new materials work well for bone repair and drug delivery. In energy, zirconia acts as an electrolyte in fuel cells and supercapacitors. It conducts ions well and stands up to heat. Advanced processing, like spark plasma sintering, makes denser, stronger ceramic materials.

Zirconia ceramics help buildings and machines last longer by stopping corrosion.

Biomedical engineers use zirconia for dental crowns, hip joints, and bone scaffolds.

The market for zirconia ceramic refractory bricks and materials grows fast in energy, aerospace, and medical fields.

As technology gets better, zirconia refractory ceramics will help make products safer, stronger, and more sustainable.

Zirconia ceramics are one of the top refractory ceramics today. They can handle high heat, strong forces, and lots of wear. Many industries use them, like aerospace, medicine, and electronics. Yttria-stabilized zirconia stays stable, so it works well for dental implants and engine parts. Experts keep studying new ways to make and use them, like 3D printing. People who want to learn more can look up science articles and engineering websites.

Zirconia is picked because it melts at very high heat. It is tough and does not get damaged by chemicals. These features make it great for ceramic refractory bricks. People use it in kilns, furnaces, and reactors. It works well in places with extreme heat.

Ceramic refractory bricks with zirconia handle heat better. They also resist wearing out. These bricks last longer than regular ones. Factories use them to keep equipment safe from heat and chemicals. This helps lower repair costs.

Yes, zirconia refractory ceramics are safe for the body. They are strong and do not break easily. Dentists and doctors use them for crowns, bridges, and joints. Patients like them because they last long and are safe.

Companies such as Yufeng Refractory sell these bricks and ceramics. They have products for steel, glass, and chemical factories. Buyers can get special products for their needs.

Refractory ceramics, like those with zirconia, stand up to heat better than metals. They do not melt or change shape easily. They also resist corrosion and thermal shock. This makes them good for furnaces and reactors.