Views: 0 Author: Site Editor Publish Time: 2025-08-25 Origin: Site

Recrystallized silicon carbide is a great pick for kiln furniture. It works well in tough jobs. This material is very strong. Kiln shelves and beams last longer with it. It can hold heavy things without breaking. Many industries use recrystallized silicon carbide. It can handle high heat and strong chemicals. It works well where other materials do not. Manufacturers trust it to give good results every time.

Recrystallized silicon carbide (RSIC) is very strong and tough. It helps kiln furniture last longer. It can hold heavy things without breaking.

RSIC can handle very high heat. It can also take quick temperature changes. It does not crack easily. This keeps the kiln working well. It also means less fixing is needed.

This material does not get damaged by chemicals. It also resists oxidation. This protects kiln parts from harm. It helps them last longer.

RSIC kiln furniture saves energy. It heats up evenly and fast. This lowers fuel costs. It is also better for the environment.

RSIC kiln furniture comes in many shapes and sizes. It fits many kiln types. This gives more choices. It also gives better support for different firing needs.

Recrystallized silicon carbide is a ceramic that is very strong and tough. It has silicon carbide grains that stick together after being heated. This heating makes a solid piece that does not break or bend easily. Recrystallized silicon carbide works well in places with high heat. Many industries use it when other materials do not work. It can hold heavy things and keeps its shape in heat and chemicals.

Making recrystallized silicon carbide takes a few steps.

Workers start with very pure silicon carbide powder.

They mix this powder with carbon and a binder like resin or wax.

The mix is shaped by slip casting, extrusion, or injection molding.

The shaped piece goes into a furnace and is heated to about 2000°C.

The binder burns away, and the silicon carbide grains stick together.

Now, the recrystallized silicon carbide is ready for kiln furniture and other hot jobs.

Tip: Sintering is the main way to make recrystallized silicon carbide. This step gives the material its special features.

Recrystallized silicon carbide is used in many ways.

The ceramics industry uses it for kiln shelves, beams, and supports.

Glass and steel companies use it for furnace parts that get very hot.

Aerospace and aviation use it for rocket nozzles and heat shields.

Car makers use it for brake discs and clutch parts that get hot and rub a lot.

Metallurgy and chemical plants use it for furnace linings and reactors.

Research labs use it for tests that need high heat.

| Industry / End-user Segment | Application Description | Market Share / Growth Trend |

|---|---|---|

| Ceramics Industry | Kiln furniture, shelves, beams | Major market share in 2023 |

| Glass Industry | Furnace components | Included in industrial segment |

| Steel Industry | Furnace components | Included in industrial segment |

| Aerospace and Aviation | Technical ceramics | Segment expected to grow |

| Automotive Industry | Brake discs, clutch parts | Segment expected to grow |

| Metallurgy and Chemicals | Furnace linings, reactors | Major share in industrial segment |

| R&D Labs | High-temperature experiments | Significant growth expected |

Recrystallized silicon carbide is good for tough jobs. More industries use it because it works well in hot places. Its many uses make it a top pick for lots of jobs.

Recrystallized silicon carbide kiln furniture is very strong. It can hold heavy things in kilns without bending. This material is hard and tough. It can carry big ceramic pieces many times. These features make it good for hard jobs in kilns.

The table below lists some important facts about its strength:

| Property | Value | Unit |

|---|---|---|

| Compressive Strength | ≥1300 | Kg/cm² |

| Modulus of Rupture (room) | ≥500 | Kg/cm² |

| Modulus of Rupture (1400℃) | ≥550 | Kg/cm² |

| Bulk Density | 2.70 - 2.75 | g/cm³ |

| Hardness | High | - |

This kiln furniture keeps its shape even when it gets hot. It lasts longer than other materials at high heat. Its strength helps stop cracks and breaks during firing.

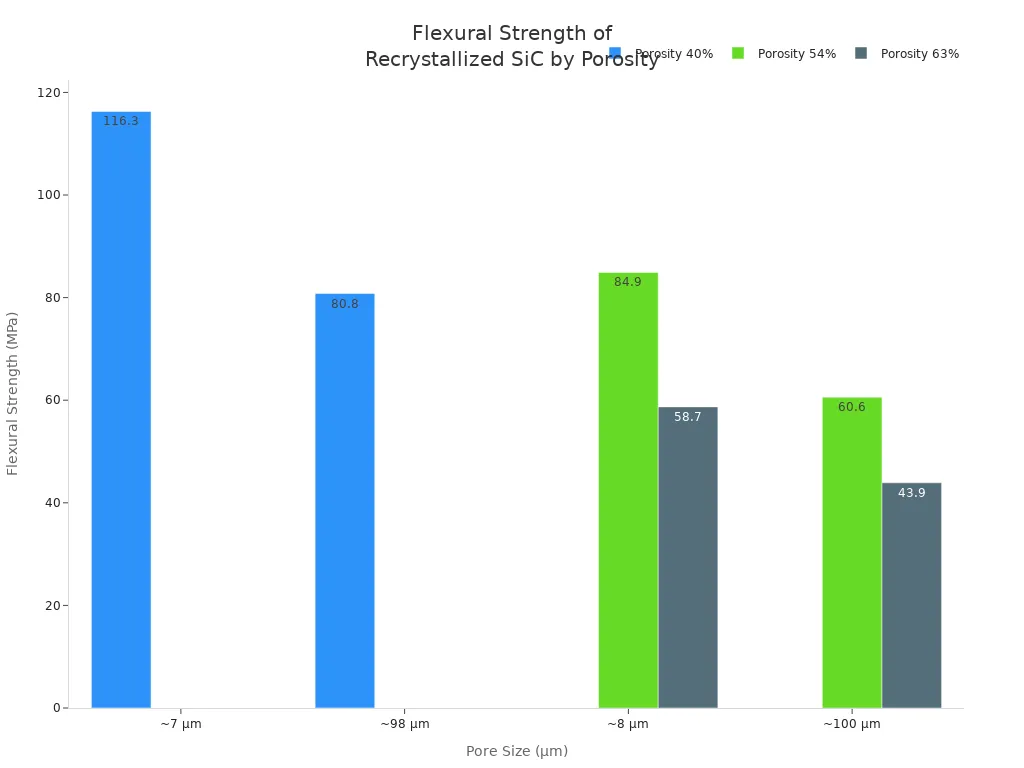

Flexural strength is also important. RSIC can be stronger than cordierite-bonded porous silicon carbide. This depends on the size of the pores and how many there are. The chart below shows how flexural strength changes with different pore sizes and porosities:

RSIC kiln furniture stays strong through many firings. Companies pick RSIC because it is tough and can hold a lot. Its hardness and strength make it one of the best for kilns.

RSIC kiln furniture can handle very high heat. It works well in kilns that get very hot. RSIC keeps its strength even up to 1650°C. This means it works for both long and short kiln runs.

Note: RSIC kiln furniture works safely from 1350°C to 1600°C. This makes it good for many types of kilns.

RSIC does not expand much when heated. Its thermal expansion is about 4.5×10⁻⁶/K. This helps stop cracks when the temperature changes fast. RSIC also spreads heat well, so shelves and supports heat up evenly. These features help protect kiln furniture from damage.

Here are some key thermal facts:

| Property | Value | Unit |

|---|---|---|

| Max. Service Temperature | 1550 - 1650 | ℃ |

| Thermal Expansion (1000℃) | 0.42 - 0.48 | % |

| Thermal Conductivity (1000℃) | 13.5 - 14.5 | Kcal/m.hr.℃ |

RSIC can go through over 100 quick heat changes of 1000°C or more. Other kiln materials often break after only 30–50 cycles. RSIC has a special structure that helps stop cracks from growing. It stays strong even after many uses.

RSIC also spreads heat up to five times better than other ceramics. This helps keep the kiln at the right temperature. Its strong and stable features make it a top pick for hot jobs.

RSIC kiln furniture does not get damaged by chemicals or air. This protects shelves and supports from gases and harsh stuff in the kiln. RSIC stands up to acids, alkalis, and other chemicals that hurt regular kiln furniture.

Tip: RSIC kiln furniture is great for places with strong chemicals and high heat. Its resistance helps it last longer.

RSIC does not break down easily in oxygen at high heat. This keeps it strong after many firings. Oxide bonded silicon carbide is also good at resisting oxidation and heat shock, but RSIC works well too. RSIC lasts longer than cordierite and mullite ceramics.

Here are some important chemical facts:

| Property | Value | Unit |

|---|---|---|

| Apparent Porosity | 7 - 8 | % |

| Resistance to Oxidation | High | - |

| Corrosion Resistance | High | - |

RSIC is used where materials must resist corrosion. Its hardness and stability protect kiln parts from chemicals and air. RSIC keeps its strength and shape even in tough places.

RSIC kiln furniture is strong, hard, stable in heat, and resists chemicals and air. These features make it a top choice for shelves, beams, and supports in hard jobs. Companies trust RSIC because it works well and lasts a long time.

RSIC kiln furniture is special because it handles heat changes well. It does not crack or break when the temperature goes up or down fast. Kilns can get hot and cool quickly. Most materials cannot handle this, but RSIC stays strong.

Recrystallized silicon carbide does not break with quick heat changes.

This helps stop cracks and damage. Shelves and supports last longer.

RSIC is tough, so you fix or replace it less often.

RSIC keeps its shape at very high temperatures.

This means longer use and steady work in the kiln.

RSIC is made by sintering. This makes it strong and full of tiny holes. It does not bend or crack after many heat cycles. The grains in RSIC are clean and help it stay strong. So, kiln furniture made from RSIC needs less fixing and lasts longer.

Note: RSIC kiln furniture can handle over 100 fast heat changes of 1000°C or more. Other materials may break after only 30–50 cycles.

RSIC kiln furniture does not expand much when heated. Most things get bigger when hot. If they grow too much, they can crack or change shape. RSIC has a low thermal expansion, so it stays the same size.

| Material | Coefficient of Thermal Expansion (×10⁻⁶/K) |

|---|---|

| Recrystallized Silicon Carbide | ~4.69 |

| Alumina (various purities) | ~8.2 |

| Cordierite | ~3.4 (qualitative low value) |

The table shows RSIC grows less than alumina and is close to cordierite. RSIC’s low expansion, about 4.6 x 10⁻⁶ at 1000°C, helps kiln furniture keep its shape. This stops bending and cracking, even with quick heat changes.

Silicon carbide’s low expansion and high heat flow help it resist heat shock. RSIC’s pure grains make this better. The way RSIC is made stops shrinking during firing. This removes stress that could cause cracks or warping. RSIC kiln furniture keeps its shape and size. This is important for stacking and holding ceramic pieces in the kiln.

Tip: Stable kiln furniture means fewer problems and better finished products.

RSIC kiln furniture is also great at fighting wear and chemicals. Kiln shelves and supports face strong chemicals, high heat, and lots of rubbing. Many materials break or rust, but RSIC does not.

Recrystallized silicon carbide stands up to strong acids, alkalis, and other chemicals. It stays strong above 1600°C, which is hotter than most kiln furniture can handle. RSIC’s strength and heat flow help it last longer in tough places.

A big chemical plant switched from stainless steel to RSIC in reactors and pipes. Equipment lasted about 40% longer. The plant spent 25% less on repairs and had fewer problems with rust. This shows RSIC works better than alumina, magnesia ceramics, and metals like stainless steel.

Callout: RSIC fights rust and chemicals, so it is a top pick for kiln furniture in ceramics, glass, steel, and chemical plants.

RSIC’s strength against wear and chemicals means it can be used many times. This saves money and time for people who run kilns.

RSIC kiln furniture is better than alumina in many ways. Both are strong and can take heat. But RSIC is tougher and stays stable longer. RSIC has a Young's modulus of about 400 GPa. Its hardness is 2400 Vickers. Alumina can handle pressure and heat too. But RSIC works better when the kiln gets really hot. RSIC keeps its shape and strength at high heat. Alumina can get weaker after a while.

| Property | RSIC Kiln Furniture | Alumina Kiln Furniture |

|---|---|---|

| Mechanical Strength | Very high; Young's modulus ~400 GPa | High |

| Hardness | ~2400 Vickers | High |

| Thermal Conductivity | 100–150 W/m·K | Good |

| Thermal Expansion | ~4.5 x 10⁻⁶ /K | Good |

| Thermal Shock Resistance | Outstanding | Excellent |

| Purity | >99.5% | >99.9% |

| Application Suitability | High-performance, high-temperature | Industrial, chemical resistance |

RSIC is also tougher when it gets hot. Studies show RSIC gets stronger as it heats up. Alumina is good for catalyst supports and grinding. But RSIC is better for hard kiln jobs.

Cordierite and mullite are used a lot in kiln furniture. They can take heat and do not expand much. But RSIC lasts longer and can take more heat. RSIC does not crack or bend after many uses. Cordierite does not expand much, but it is not as strong as RSIC. Mullite works in medium heat, but RSIC is better in very hot places.

RSIC kiln furniture does not wear out or rust easily.

Cordierite and mullite can wear down faster in tough kilns.

RSIC can hold heavier things and keeps its shape.

Tip: RSIC kiln furniture is best for kilns that get very hot or need to last a long time.

RSIC kiln furniture costs more at first. But it saves money later. It has high thermal conductivity, about 25–35 W/m·K. This helps kilns heat up fast and evenly. It uses less energy and fuel. RSIC lasts longer, so you do not have to replace it often. Less downtime means more work gets done and fewer repairs.

RSIC kiln furniture helps kilns use less energy.

Operators pay less for fuel and make less carbon.

RSIC lasts a long time, so it is a smart buy.

RSIC kiln furniture works better, lasts longer, and saves money compared to alumina, cordierite, or mullite. It helps kilns run well and saves money over time.

Recrystallized silicon carbide kiln furniture can be made in many shapes. Makers can create beams, plates, supports, tubes, rollers, nozzles, crucibles, and saggers. These can be any size or shape needed. This helps RSIC kiln furniture fit different kilns and firing jobs. OEM services and custom work help match kiln furniture to each kiln. For example, plates can have holes to let out heat stress. Beams can be longer or thicker for more support.

| Design Option Type | Description / Function | Customization Features |

|---|---|---|

| Silicon Carbide Plate | Holds items during firing; strong and resists chemicals | Custom sizes, shapes, drilling |

| Silicon Carbide Beam | Gives support; handles high heat | Custom sizes; OEM service available |

| Silicon Carbide Roller | Used in roller kilns at high heat | Custom sizes and shapes |

| Silicon Carbide Crucible | Holds things being fired; lasts a long time | Custom sizes and shapes |

RSIC does not shrink when fired. It keeps its shape and size, even for big or tricky designs. Other materials, like hot isostatic pressed SiC, cannot do this as well. RSIC can be shaped by casting or extrusion. These ways make kiln furniture that is exact and steady.

RSIC kiln furniture has some problems. Fast heating and cooling can still cause cracks, even though RSIC handles heat changes well. Some chemicals, like alkali vapors or chlorine gases, can hurt the grain edges and make the surface react. Bad setup or design can make weak spots, which may break early. Heavy loads or poor support can also cause cracks or move parts out of place.

| Limitation Category | Description |

|---|---|

| High Material Cost | Needs very pure materials and high heat to make, so it costs more. |

| Size and Shape Limitations | Hardness after firing makes cutting big or tricky shapes hard and costly. |

| Oxidation Issues | Low-purity RSIC can react with molten glass, making layers that mix with the melt. |

When picking RSIC kiln furniture, people should think about a few things:

Check what material will be fired and what it needs.

Know how hot the kiln will get.

Think about the size and weight of things to be fired.

Pick the best shape and setup for the kiln furniture.

Make sure RSIC is light and strong for saving energy and easy moving.

Look for high purity and chemical safety to stop contamination.

Choose products that spread heat well for even firing and less energy use.

Match the kiln furniture design to the kiln’s heat, strength, and chemical needs.

Tip: Makers should also think about green rules and use digital tools to watch and care for kiln furniture. These steps help save energy and meet eco-friendly goals.

RSIC kiln furniture is strong and lasts a long time. It helps save energy and money. Operators spend less over time because of these features:

| Feature/Benefit | Impact on Cost Savings |

|---|---|

| High thermal conductivity | Over 30% energy savings |

| Long service life | 500–1000+ cycles, fewer replacements |

| Excellent shock resistance | Less cracking, lower maintenance |

| Resistance to oxidation/wear | Reduced material degradation |

These features mean kilns stop less often. Firing stays steady and production goes up. Facility managers should check their kiln furniture. They can talk to experts to find the best choice for their needs.

RSIC Kiln Furniture is made with recrystallized silicon carbide. This material is very strong and does not get damaged by heat or chemicals. RSIC lasts longer than alumina, cordierite, or mullite kiln furniture. Many companies pick RSIC for hard jobs in kilns.

RSIC Kiln Furniture can handle quick changes in temperature. It does not crack or break when it gets hot or cools fast. The way RSIC is built helps it stay strong after many heating and cooling cycles.

RSIC Kiln Furniture can last through hundreds of firings. Its strength and toughness help it last longer than other materials. Workers do not need to replace RSIC as often, so they save time and money.

RSIC Kiln Furniture uses very pure silicon carbide. It does not make ceramics dirty during firing. Many companies use RSIC to make food-safe and clean ceramic products.

RSIC Kiln Furniture comes as plates, beams, rollers, crucibles, and special shapes. RSIC keeps its shape after being fired. Custom sizes and shapes help it fit different kilns and firing jobs.