Views: 0 Author: Site Editor Publish Time: 2025-08-20 Origin: Site

People look for other options to fire bricks when firebricks cost too much, are hard to find, or do not fit their project. Some common choices are Refractory Bricks, refractory concrete, insulating fire bricks, ceramic fiber, and castable refractory. Each choice has different heat resistance, safety, and price. For example, soft fire bricks are simple to use and save money. Ceramic fiber keeps in heat very well but is not good for tough jobs. More people want firebrick alternatives now, especially in glass and steel factories. This guide helps readers pick the safest and best material for their project.

People look for firebrick alternatives because firebricks cost a lot, are hard to buy, or do not work for some jobs. Different things like refractory concrete, insulating fire bricks, ceramic fiber, and castable refractory have different heat resistance, prices, and safety features. Pick your material based on how much heat your project needs, safety rules, and how much money you have. This helps make sure your project lasts and stays safe. Insulating fire bricks and ceramic fiber help save energy by keeping heat inside. But they are not strong enough for direct flames or heavy weight. Always follow safety rules and ask experts for help. This helps you choose the best material and keeps you safe from harm.

Many builders and homeowners want other choices because fire bricks can cost a lot and are not always easy to find. Firebrick uses cheap clay, but it can still be pricey in some places. In the U.S. and Germany, firebrick is often cheaper than fancy storage systems. But it can still be expensive for small jobs. Sometimes, fire bricks and refractory bricks are not sold nearby. People might buy ceramic tiles or concrete blocks instead. These are easier to get and cost less. But they do not work as well with heat or keep heat in like firebrick.

Note: Getting fire bricks or other options depends on many things. Rules from the government, how the economy is doing, and even the weather can change how easy it is to buy these materials. In Asia Pacific, more people want firebrick because new factories and cities are being built. In North America and Europe, old industries and safety rules keep demand steady. In some places, clay bricks or refractory bricks are hard to find, so builders use what they can get.

A few other things matter too:

Prices for raw materials can go up and down fast, so firebrick supply is not always steady.

Environmental rules can stop companies from making lots of firebrick.

Buyers can choose other suppliers or materials if they want.

Different jobs need different materials. Some ovens, fireplaces, or kilns need to handle high heat, so fire bricks and refractory bricks are used. For smaller or easier jobs, people might pick common bricks, ceramic fiber, or castable refractory. Concrete blocks are strong and cheap, but they do not do well with heat and can crack in wood ovens. Ceramic tiles are a cheap choice, but they do not keep heat as well as firebrick.

The kind of project matters too. For example:

Outdoor pizza ovens need to keep heat in, so firebrick or refractory brick is best.

Simple grills or fire pits can use common bricks or concrete blocks if they do not need to handle high heat.

Big kilns and furnaces almost always use fire bricks or refractory bricks because they last a long time.

Picking the right material depends on how much heat the job needs, safety, and how much money you have. Builders must think about cost, how easy it is to get, and how well it works to choose the best one.

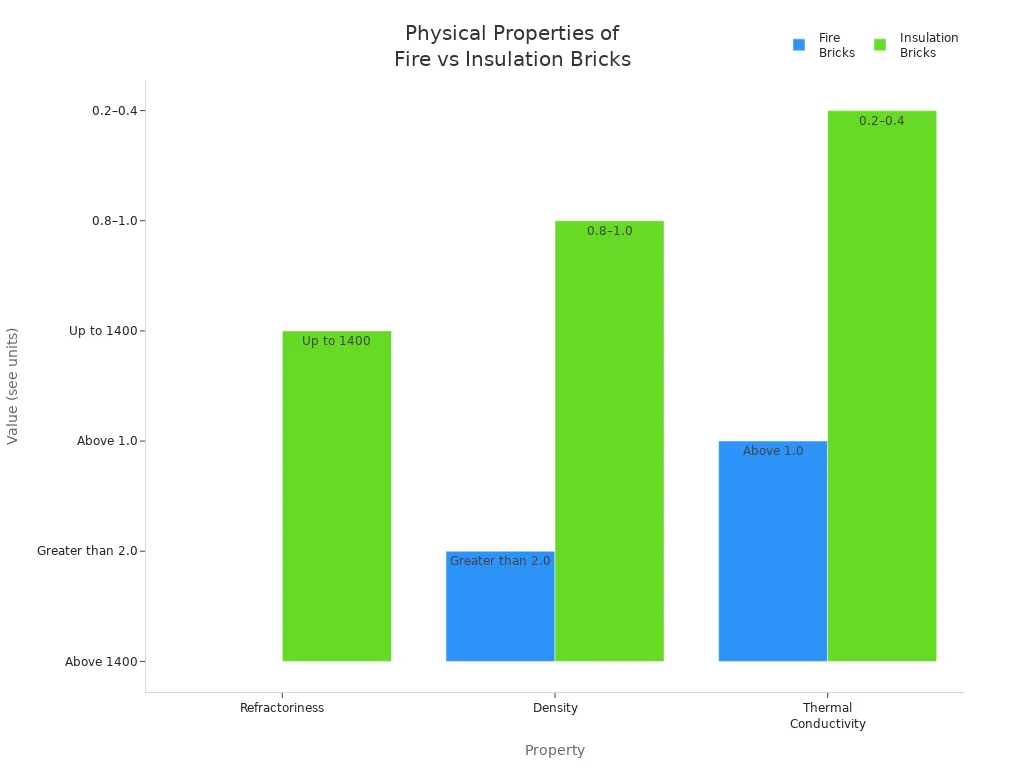

Refractory bricks and fire bricks both work with high heat. But they are not the same. Fire bricks are very dense and strong. They can take heat over 1400°C. Refractory bricks use fireclay, silica, or alumina. These bricks are tough and can face direct flames.

Insulation bricks are a kind of firebrick. They are lighter and not as dense. They help keep heat inside ovens or kilns. Their density is much lower than fire bricks. Insulation bricks are between 0.8 and 1.0 g/cm³. Fire bricks are over 2.0 g/cm³. Insulation bricks do not hold heavy things. But they help save energy.

| Property | Fire Bricks (Refractory Bricks) | Insulation Bricks |

|---|---|---|

| Refractoriness | Above 1400°C | Up to 1400°C |

| Density | Greater than 2.0 g/cm³ | Between 0.8 and 1.0 g/cm³ |

| Thermal Conductivity | Above 1.0 W/m·K | 0.2–0.4 W/m·K |

| Mechanical Strength | High | Moderate |

| Primary Function | Withstand direct flame and provide structural support | Thermal insulation and energy efficiency |

| Typical Composition | Fireclay, silica, sometimes alumina additives | Lightweight, porous materials |

| Common Applications | Furnace linings, kilns, fireplaces | Insulation layers in thermal equipment |

Studies show firebrick waste can make cement mortars stronger. It also helps them handle heat better. So, fire brick refractory materials are tough. They also help other building materials last longer.

Different firebricks and refractory bricks are good for different jobs. Experts say to use them like this:

Hard fire bricks are best for kilns, chimneys, and fireboxes. They give strong support and last long.

Soft fire bricks, or insulating firebricks, are good for electric kilns or liners. They keep heat in but cannot hold heavy things.

Fire clay bricks are good for fireplaces and ovens. They cost less but do not fight chemicals as well.

Graphite refractory bricks work in glass or steel factories. They can take very high heat and harsh chemicals.

Fire brick refractory materials line furnaces, stoves, and wood ovens. They protect from heat and stop damage.

Fire bricks and refractory bricks are important for high-heat jobs. The best one depends on heat, weight, and chemicals in the job.

Picking the right material for hot projects matters a lot. Many people want something cheaper or easier to find than fire bricks. Some also need materials that fit their project better. Here are the top choices. Each one has different heat resistance, safety, price, and best uses.

Refractory concrete is a good choice for strong heat resistance. It uses special cements and rocks that can take very high heat. Some types have lots of alumina. These can handle up to 1900°C. That is hotter than most fire bricks, which only go up to 1400°C.

Refractory concrete is strong and does not crack easily. It can handle quick changes in heat better than fire bricks. People use it in factories, but it also works for ovens and kilns at home.

Price matters too. In the U.S., firebrick costs less and is easier to use than refractory concrete. A small bucket of castable refractory cement costs about $55. A big bag costs around $39. This makes refractory concrete cost more per pound than fire bricks for most homes. In Australia, refractory concrete is used more because fire bricks cost more there.

Refractory concrete works best for:

Ovens and kilns with special shapes

Repairs where bricks do not fit

Jobs that need very high heat resistance

Tip: Mix and cure refractory concrete carefully. If you do not, it can crack or break when heated.

Insulating fire bricks keep heat inside ovens and kilns. They are also called insulation fire brick or insulating bricks. These bricks have lots of tiny holes and are light. They do not let heat pass through easily. Their thermal conductivity is much lower than regular fire bricks. This makes them great for insulation.

Here is a table that shows how insulating fire bricks compare to regular fire bricks:

| Property | Insulating Fire Bricks (IFBs) | Traditional Fire Bricks |

|---|---|---|

| Thermal Conductivity | Low (0.2–0.4 W/m·K) | High (>1.0 W/m·K) |

| Density | Low (0.8–1.0 g/cm³) | High (>2.0 g/cm³) |

| Max Service Temp | Up to ~1400°C | Above 1400°C |

| Mechanical Strength | Low | High |

| Main Usage | Insulation layers | Direct flame contact |

| Workability | Easy to cut and install | Needs special tools |

| Cost | Lower | Higher |

Insulating bricks are easy to cut and shape. They help ovens and kilns heat up and cool down faster. This saves energy. But they are not as strong as fire bricks. Do not use them where heavy things or direct flames are present.

Safety matters too. Using the wrong brick can make things unsafe. It can also affect insurance. Insulating fire bricks are best for insulation layers, not for touching fire.

Best uses for insulating bricks:

Inside layers of kilns and ovens

Electric kilns

Projects that need to save energy

Note: Check if insulating bricks meet safety rules before using them at home.

Common bricks are easy to find and cost less than fire bricks. Builders use them for chimneys or the outside of fireplaces. These bricks can handle some heat, but not as much as fire bricks.

Common bricks are light and have lots of holes. They soak up water. When heated, the water turns to steam. This can make the brick crack or pop. The holes inside can also expand and break apart in high heat. This makes them unsafe for direct flames or very hot places.

People use common bricks for:

The outside of fireplaces

Chimney stacks

Fire pits with low heat

But do not use common bricks inside fireboxes or kilns. They can crack, flake, or break after being heated many times. This can be dangerous and cause problems.

Warning: Never use common bricks where there are flames or high heat. They do not give enough heat resistance or safety.

Ceramic fiber is light and bends easily. It is used for insulation in hot places. You can buy it as blankets, boards, or paper. Ceramic fiber can take short bursts of heat up to 1430°C. For long use, it works best about 200°C lower. It is good for insulation, but not for touching flames or holding up heavy things.

Ceramic fiber is easy to put in and shape. It keeps heat inside ovens and kilns. But it is not as strong as fire bricks. Use it as an extra insulation layer, not as the main building material.

Safety is very important with ceramic fiber. The tiny fibers can hurt your lungs if you breathe them in. Over time, this can cause health problems. Workers should wear masks and gloves. Keep the area clean and throw away waste the right way. After being heated, ceramic fiber can change and become even more dangerous if touched.

Here is a table with safety tips for ceramic fiber:

| Health and Safety Consideration | Description |

|---|---|

| Carcinogenic Classification | May cause cancer if inhaled over time |

| Exposure Limits | Strict workplace limits apply |

| PPE | Masks and gloves recommended |

| Waste Disposal | Special handling and disposal needed |

| Additional Risks | Can become more hazardous after use |

Ceramic fiber works best for:

Extra insulation in kilns and ovens

Jobs that need light, bendable insulation

Places where bricks do not fit

Note: Always follow safety rules with ceramic fiber. Wear protective gear and throw away waste the right way.

Castable refractory is a mix of special cements and rocks. You can pour or mold it into any shape. This helps with repairs, custom ovens, or places where bricks do not fit. Castable refractory can take high heat. But it does not store heat or hold up as well as fire bricks.

A 4-pound pack of castable refractory cement costs about $30. It can take heat up to 2822°F (about 1550°C). Strong castables can be almost as tough as fire bricks. But you must mix and cure them carefully. If not, steam can build up and cause cracks.

Here is a table that compares fire bricks and castable refractory:

| Aspect | Fire Bricks | Castable Refractory |

|---|---|---|

| Density & Heat Storage | High | Lower |

| Structural Integrity | Strong, good for ovens | Lower unless high-density is used |

| Application | Needs shaped bricks | Can be poured or sprayed |

| Durability | Very durable, resists cracking | Easier to repair, but less tough |

| Heat Resistance | Handles repeated heating well | Good, but less heat storage |

| Handling Precautions | Few | Needs careful curing |

Castable refractory works best for:

Repairs in ovens and kilns

Custom shapes or hard-to-reach spots

Jobs where pouring is easier than laying bricks

Tip: Always follow the instructions for mixing and curing castable refractory. This helps stop cracks and problems.

Comparison Table: Firebrick Alternatives

| Alternative | Max Temp (°C) | Heat Resistance | Insulation Value | Safety | Cost | Best Use Cases |

|---|---|---|---|---|---|---|

| Refractory Concrete | 1800–1900 | Excellent | Good | Good (if cured) | Moderate-High | Custom ovens, kilns, repairs |

| Insulating Bricks | ~1400 | Good | Excellent | Good (if used right) | Lower | Insulation layers, electric kilns |

| Common Bricks | ~1000 | Poor | Poor | Poor (in fire) | Low | Chimneys, outer shells |

| Ceramic Fiber | 1050–1430 | Good (insulation) | Excellent | Needs PPE | Moderate | Extra insulation, odd shapes |

| Castable Refractory | ~1550 | Good | Good | Good (if cured) | Moderate | Repairs, custom shapes |

Which Alternative Fits Each Project?

Ovens and Kilns: Use refractory concrete and fire brick refractory for main parts. Add insulating bricks and ceramic fiber for extra insulation.

Fireplaces: Line the firebox with fire bricks or fire brick refractory. Use common bricks only for the outside.

Repairs or Custom Shapes: Castable refractory is easy to mold and patch. Ceramic fiber fills gaps and adds insulation.

Always pick the material that matches the heat and safety needs of your project. If you are not sure, ask a professional.

Heat resistance is very important when picking firebrick alternatives. Castable and plastic refractory products can take very high heat, even over 3000°F. This makes them great for places like steel plants and glass factories. Insulating bricks also work well in hot places, but they are not as tough as castable refractories. Ceramic fiber products, such as Fiberfrax® cloth and tapes, can handle up to 2300°F. These are good for many ovens and kilns. But ceramic fiber does not give strong support like refractory bricks do. Builders should think about thermal shock resistance too. This matters for projects that heat up or cool down fast. Insulating bricks help stop cracks by acting as a buffer against quick heat changes.

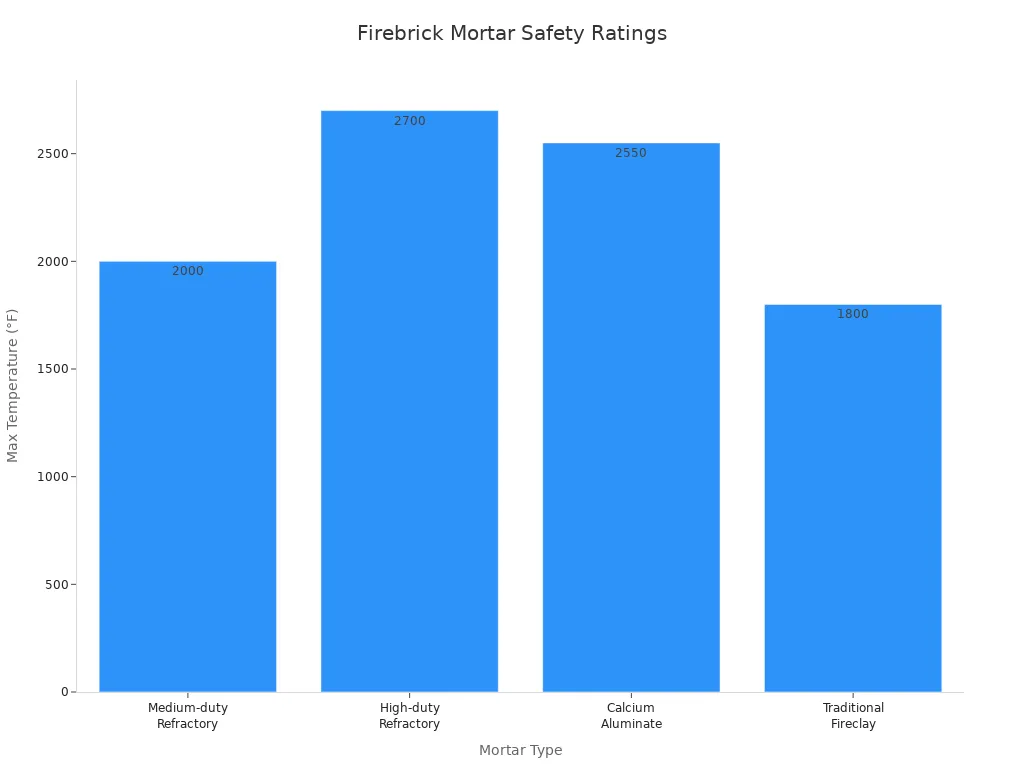

Safety and cost are big things to think about when picking materials. Building codes say what you must use for firebox and flue linings. Medium-duty refractory mortars meet ASTM C-199 and NFPA-211 codes. These are safe for fireplaces at home and outdoor fire pits. High-duty refractory mortars are best for big kilns and forges. They cost more and are harder to use. Calcium aluminate mortars are very safe and last long in bad weather. Traditional fireclay mortars do not meet new safety codes. Insulating bricks give good insulation and usually follow the rules if used right. The chart below shows the highest temperatures for different mortar types:

| Mortar Type | Maximum Temperature | Typical Applications | Code Compliance & Safety Notes |

|---|---|---|---|

| Medium-duty Refractory | Up to 2,000°F | Residential fireplaces, outdoor fire pits | Meets ASTM C-199 and NFPA-211 codes; suitable for typical residential use and code compliant |

| High-duty Refractory | Up to 2,700°F | Commercial kilns, forges | Higher temperature resistance; used in commercial settings; more expensive and harder to work with |

| Calcium Aluminate | Up to 2,550°F | Premium residential, outdoor ovens | Superior longevity and weather resistance; code compliant; premium option for exposed masonry |

| Traditional Fireclay | Up to 1,800°F | Historical restoration only | Not code compliant; authentic appearance but unsuitable for modern safety standards |

Using the right material for the job keeps things safe and working well. Experts say firebricks and refractory bricks are best for pizza ovens. They hold heat and do not wear out fast. Insulating bricks are good for electric kilns and for insulation layers. But do not use them where there are direct flames. Ceramic fiber is good for odd shapes and extra insulation. You must wear safety gear when using it. Castable refractory is best for repairs and custom shapes. Concrete blocks and ceramic tiles do not work for very hot jobs.

Decision Guide:

For ovens and kilns: Use refractory bricks or castable refractory for the main part. Add insulating bricks for extra insulation.

For fireplaces: Put refractory bricks inside the firebox. Use common bricks only on the outside.

For repairs or custom shapes: Pick castable refractory or ceramic fiber for more flexibility.

Always ask a certified masonry expert before picking and using firebrick alternatives. Experts help you choose the right material, follow safety rules, and keep your project strong. Regular checks and advice from pros help stop fires and damage.

Picking the best firebrick alternative depends on heat, insulation, and what your project needs. Builders need to look at material safety labels, how long it lasts, and if it is good for the environment. Safety is most important. Always wear safety gear, use the right mortar, and let things dry fully. People often make mistakes by not checking the right heat level or using the wrong size. If you need help, ask groups like IOM3 or trusted sellers. Making a smart choice keeps your project safe and strong. ️ Choose the right refractory bricks to make sure your work lasts and stays safe.

Refractory Bricks help ovens and kilns handle high heat. They protect buildings from getting damaged. Many factories use them for making glass and steel. Ceramic factories also use them. Yufeng Refractory Bricks last a long time and resist heat well.

Common bricks do not work in pizza ovens. They break and crack when heated. Refractory Bricks from Yufeng keep heat inside better. They last longer and work best for pizza ovens.

Ceramic fiber is good for insulation. It does not hold heavy things. Refractory Bricks can face flames and give support. Yufeng ceramic fiber works for insulation layers. Refractory Bricks are better for oven walls.

Refractory Bricks are safe for fireplaces at home. They stop heat from causing damage. Yufeng Refractory Bricks pass strict safety checks. Homeowners use them to build safe fireplaces.

Yufeng Refractory sells many kinds of Refractory Bricks online. Buyers can go to yufengrefractory.com for info and prices. The company ships to many countries and gives expert help.