Views: 0 Author: Site Editor Publish Time: 2025-08-28 Origin: Site

Refractory installation is putting special bricks inside hot equipment. These bricks can handle very high heat. Equipment like furnaces and kilns use these bricks. The bricks are called fire bricks or refractory bricks. They help protect metal, glass, and cement plants from heat. Fire brick is strong and does not break down from heat or chemicals. About one-third of all refractory bricks are used in industrial furnaces. These bricks line and shield the furnaces. The global market for fire bricks is growing. It reached over $4 billion in 2024. Industries want better ways to keep equipment safe and working well.

Refractory bricks are also called fire bricks. They protect equipment from very high heat and chemicals. This makes furnaces and kilns safer. It also helps them work better.

You must pick the right refractory brick. This depends on heat, chemicals, and stress. The right choice keeps things safe for a long time. It also saves energy.

Good installation needs careful planning. You must pick the right materials. Skilled workers must put the bricks in place. After that, you need to check the work. This helps stop cracks and failures.

Regular checks and care help bricks last longer. This saves energy. It also stops costly repairs and keeps equipment safe.

Do not make common mistakes. Clean surfaces well. Pick the right bricks. Use trained workers. Plan carefully and follow the instructions from the maker.

A refractory brick is a special brick that can take very high heat. Factories use these bricks inside furnaces and kilns. These places get extremely hot. Regular bricks would break in this heat, but refractory bricks do not. People also call them fire bricks or firebricks. These bricks keep the inside of equipment safe from heat, flames, and chemicals.

Different raw materials are used to make refractory bricks. The material depends on where the brick will go and what it will face. Here are some main raw materials:

Siliceous raw materials: These have lots of silicon dioxide. They come from quartz, quartzite, flint, and sandstone.

Fireclay raw materials: These are mostly kaolinite and free silica. Fireclay can be hard or soft, depending on how it is used.

High alumina raw materials: These include bauxite, fused and sintered alumina, and minerals like mullite and kyanite. They have lots of alumina, which helps the brick handle high heat.

Basic raw materials: These come from magnesite and dolomite. They have magnesium oxide and calcium oxide.

Zirconia-based raw materials: These use zircon, which has zirconium dioxide and silicon dioxide.

Chrome-based raw materials: These use chromite ore, which has magnesium, iron, and chromium oxides.

Tip: Picking the right raw material is important. It helps the refractory brick work well in hot places.

Refractory bricks come in many shapes and sizes. Some are straight, and some are curved or wedge-shaped. Curved bricks fit round furnaces. Each brick type has a special job. Some resist heat, some resist chemicals, and some handle quick temperature changes.

Good fire bricks have special features for high heat places. These features help the bricks last longer and protect equipment better than regular bricks.

| Property | Fire Bricks | Common Bricks |

|---|---|---|

| Heat Resistance | 1,200°C–1,800°C | 600°C–800°C |

| Thermal Conductivity | Low (especially insulating grades) | Higher, loses heat faster |

| Composition | Alumina, silica, magnesia, refractory minerals | Clay, sand, natural materials |

| Porosity | Low porosity, denser | More porous |

| Thermal Shock Resistance | High, resists cracking and spalling | Low, prone to cracking/spalling |

| Typical Use | High-heat applications (kilns, furnaces, pizza ovens) | General construction |

Fire bricks can take much higher heat than common bricks. They do not let heat escape easily. This makes them good at keeping heat inside furnaces and ovens. It also helps save energy.

Fire bricks are dense and strong. They do not soak up much water or gas. This helps them resist damage from chemicals and quick temperature changes. This is called thermal shock resistance. When a furnace heats up or cools down fast, fire bricks do not crack as easily as regular bricks.

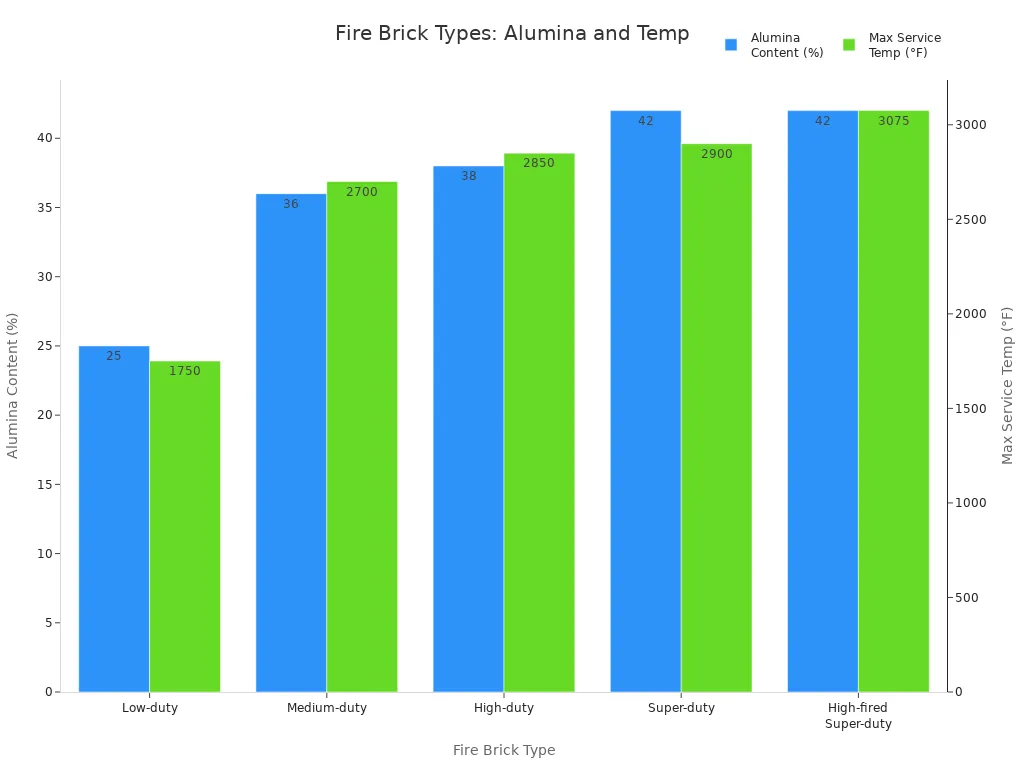

The table below shows different fire brick types. It compares their alumina content and the highest temperature they can handle:

| Fire Brick Type | Alumina Content (%) | Max Service Temperature (°F) | Key Characteristics and Uses |

|---|---|---|---|

| Low-duty | 24–26 | 1750 | Used for fireplace chimneys; lower temperature applications |

| Medium-duty | 34–38 | 2700 | Backup linings, lower-temp kilns and chimneys |

| High-duty | 36–40 | 2850 | Boilers, ceramic kilns, chimneys; first-quality firebrick |

| Super-duty | 40–44 | 2900 | Higher temperature applications; improved resistance |

| High-fired Super-duty | 40–44 | 3000–3150 | Lower porosity, higher strength, better chemical resistance |

Firebricks last a long time in tough places. In factories, refractory bricks can last from 1 to over 5 years. How long they last depends on the material, how they are put in, and how they are cared for. For example, glass furnace linings may last up to 8 years. Steel ladle linings might need repairs sooner.

Some important features of refractory fire bricks are:

High heat resistance: They can take heat from 1,200°C to 1,800°C or more.

Low thermal conductivity: They keep heat inside, so furnaces and ovens work better.

Strong mechanical strength: They can hold heavy loads and do not wear out fast.

Chemical stability: They do not react with molten metals, slag, or chemicals.

Thermal shock resistance: They do not crack when heated or cooled quickly.

Low porosity: They do not soak up much water or gas, so they last longer.

Note: Fire bricks are much better than common bricks for hot jobs. They keep equipment safe, save energy, and need fewer repairs.

Refractory materials like alumina, silica, magnesia, and zirconia give fire bricks their special features. These materials form strong crystals when fired at high heat. This makes the bricks tough and stable. Fire bricks also help keep furnaces and kilns at the right temperature. This helps make better steel, glass, and cement.

Many factories use refractory bricks to protect equipment. These bricks line furnaces, kilns, and reactors. They keep heat inside and stop damage to the outside. The table below shows how different industries use fire bricks:

| Industry | Primary Applications of Fire Bricks |

|---|---|

| Metallurgy | Furnace linings in steelmaking and non-ferrous metal production; withstands extreme heat and corrosive environments |

| Glass | Lining of high-temperature kilns and furnaces; provides thermal insulation and heat protection |

| Ceramics | Kiln linings requiring precise temperature control and uniform heating |

| Cement | Kiln linings to resist high temperatures and chemical exposure during cement production |

| Others | Specialized uses in power plants, chemical processing, and waste incineration involving high thermal cycling and corrosive conditions |

Steel plants use refractory bricks in blast furnaces and ladles. These bricks face molten metal and quick heating. Glass factories need bricks that resist heat and chemicals from melted glass. Ceramic makers use fire bricks in kilns to keep heat steady for pottery and tiles. Cement plants use refractory bricks in rotary kilns. These kilns get very hot and change raw materials into cement. Power plants and waste incinerators use these bricks to protect boilers and burning chambers.

Fire bricks are needed where regular bricks cannot handle heat. They help factories work safely and save energy.

Refractory bricks are also used in homes and businesses. Many people use fire bricks for safety and better performance. The table below lists common uses:

| Setting | Common Uses of Fire Bricks |

|---|---|

| Residential | - Lining fireplaces to withstand high temperatures |

| - Chimney linings for safe and efficient gas release | |

| Commercial/Industrial | - Construction of kilns and furnaces for pottery, metalworking, glassblowing |

| - Insulation and structural support in boilers and incinerators | |

| - Refractory repairs in industrial equipment requiring heat resistance |

Homeowners pick fire bricks for fireplaces and wood stoves. These bricks keep the firebox safe and help it last longer. Chimneys with refractory bricks can carry away hot gases safely. Restaurants and bakeries use fire bricks in pizza ovens and bread ovens. This helps ovens get hot enough for baking.

Workshops use refractory bricks in pottery kilns and metal furnaces. These bricks insulate and protect equipment from heat. Many businesses use fire bricks to fix boilers and other machines that get very hot.

Tip: Fire bricks last longer than regular bricks in hot places. They help homes and businesses stay safe and use less energy.

There are different types of refractory bricks. Each type works best in certain places and for certain jobs. Knowing about these types helps people pick the right bricks for their needs.

Acid bricks are also called acid-resistant bricks. They are made from good clay, bauxite, and quartz. These bricks can stand up to strong acids and very high heat. They do not soak up much water and are very strong. This makes them good for chemical plants, food factories, and sewage places. The table below shows what makes acid bricks special and where they are used:

| Defining Characteristics | Description |

|---|---|

| Acid Resistance | Works well against acids like sulfuric and hydrochloric |

| Mechanical Strength | Very strong and hard to break |

| Water Absorption | Does not soak up much water |

| Typical Uses | Used in chemical tanks, pipes, food plants, and sewage |

High alumina bricks have at least 55% alumina. These bricks can take a lot of heat and are very strong. They also do not get damaged by chemicals. Factories use them in blast furnaces, rotary kilns, and steel making. High alumina bricks last longer and do not crack as easily as fireclay bricks. They also help save energy by keeping heat inside.

Used in steelmaking, cement kilns, glass tanks, and oil plants.

Good because they last long, handle heat changes, and work for many years.

Silica bricks have a lot of silica in them. They can take heat up to 1730°C. These bricks are used in very hot places like coke ovens and furnace roofs. Silica bricks do not change shape when hot and resist acid slags. But they must be heated and cooled slowly or they might crack, especially if it is below 300°C.

Best for coke oven walls, glass furnaces, and hot stoves.

Not good with quick temperature changes and need careful handling.

Magnesia-carbon bricks are made from magnesia and graphite. They can take very high heat and do not get worn down by slag or heat changes. Steel factories use them in ladles, converters, and furnace walls. The carbon in these bricks stops steel and slag from sticking. This helps furnaces last longer and makes better steel.

Good because they last long, do not rust, and need less fixing.

Fireclay bricks are made from natural clay and have some alumina. They can take heat up to 1500°C and handle quick heat changes. Fireclay bricks cost less than other bricks. They work well in fireplaces, ovens, and glass furnaces. These bricks give good performance for the price and are used for medium heat jobs.

Tip: When picking refractory bricks, think about how hot it gets, what chemicals are there, how much stress the bricks will take, and the cost. Picking the right brick keeps things safe, saves money, and helps equipment last longer.

Putting in refractory brick takes care and attention. This helps equipment last longer and work better. Every step is important, from getting ready to checking the finished job. Here is a simple guide to the main steps.

Preparation comes first and is very important. Workers need to make sure the site is safe and ready. Here is a list of steps for good preparation:

Gather all tools and materials needed for the job. Workers use trowels, brick saws, levels, rubber mallets, measuring tapes, and safety gear.

Put on gloves and goggles before starting work. Dust masks or respirators help keep workers from breathing in silica dust.

Work in a place with good airflow. This keeps dust and fumes away from workers.

Keep a first-aid kit close by for quick help. It is important in case someone gets hurt.

Handle each refractory brick gently to avoid chips or cracks. Do not drop or hit the bricks.

Clean the base surface with a wire brush. Remove all dust, grease, and loose pieces.

Use a level to check the base. The surface must be flat and stable.

Make sure the area is dry before starting. Wet surfaces can make the mortar and bricks weak.

Mark layout lines on the surface. These lines help keep the bricks straight and spaced evenly.

Tip: If you skip preparation, the lining can have weak spots. Bricks may come loose or fail early.

Some common problems during preparation are missing safety gear, dirty surfaces, or uneven bases. Workers can avoid these by following each step and checking their work.

Picking the right refractory brick is very important. The type of brick affects how well the lining handles heat, chemicals, and stress.

Choose a refractory brick that matches the temperature and chemical needs. High alumina bricks work well in steel furnaces. Acid bricks are good for chemical tanks.

Check the brick’s thermal conductivity. Lower numbers help keep heat inside and save energy.

Look for bricks with high thermal shock resistance. These bricks do not crack when temperatures change quickly.

Make sure the brick has good chemical resistance if it will face acids or slag.

Pick bricks with strong mechanical strength for heavy loads or vibration.

The right material helps the lining last longer and reduces repairs. It also keeps equipment safe. Using the wrong grade can cause erosion, softening, or even failure under high heat. Workers should ask experts or suppliers if they are not sure which refractory brick to use.

Note: New refractory materials, like nanotechnology and new ceramics, can make bricks stronger and last longer. Using the best material can lower maintenance costs by up to 20%.

There are different ways to install refractory brick. The method depends on the type of brick, the shape of the equipment, and the job’s needs. Here are the most common methods:

Casting: Workers pour wet refractory mix into forms. This gives a smooth finish and strong bond. It works well for custom shapes and solid linings.

Ramming: Workers use hammers or pneumatic tools to pack plastic refractory into place. This fits complex shapes and tight spaces.

Shotcrete: A machine sprays a wet, low-cement refractory mix at high speed onto surfaces. This is fast and covers large areas quickly.

Gunite: Workers spray a dry refractory mix using compressed air. Water mixes at the nozzle. This is portable and good for hard-to-reach spots.

Each method has its own benefits. Casting makes precise shapes and cures solidly. Ramming works for odd shapes. Shotcrete and gunite save time and are good for repairs or big surfaces.

Tip: Skilled workers are needed for shotcrete and gunite. Good mixing and application stop weak spots and cracks.

Common problems during installation are uneven joints, poor compaction, and weak anchoring. These can cause cracks, loose bricks, or lining failure. Workers should:

Clean and roughen smooth surfaces before laying bricks.

Use the right mortar and keep joint thickness even.

Compact unshaped materials well to avoid air pockets.

Use strong anchors and put them at the correct depth.

| Challenge Category | Specific Challenge Description | Solution Summary |

|---|---|---|

| Improper Substrate Surface | Smooth or oily surfaces cause poor bonding and overheating. | Clean with wire brush or sandblast; roughen surface; use bonding agent. |

| Wrong Material Selection | Using the wrong brick leads to erosion and softening. | Replace with correct grade after consulting supplier. |

| Installation Errors | Uneven joints or poor compaction cause cracks and weak spots. | Repair cracks, replace bricks, enforce quality control. |

| Poor Anchoring | Weak anchors cause bricks to fall off. | Use qualified anchors, embed to design depth, test anchorage. |

Alert: Always leave space for expansion joints. Without them, bricks can crack or break as they heat up and cool down.

After installing refractory brick, workers need to check the lining. This makes sure it is safe and strong. These checks help find problems early and keep equipment working well.

Look at the lining for cracks, chips, or loose bricks. Check for signs of wear or spalling.

Measure the thickness of the lining with ultrasonic gauges. This helps find thin spots or erosion.

Use thermocouples or infrared cameras to check for hot or cold spots. Uneven temperatures can mean trouble.

Test for chemical reactions between the brick and any materials inside the equipment.

Check for risks like lining collapse or gas leaks. Safety is always first.

Plan regular maintenance and follow proper installation steps every time.

Tip: Regular checks and good installation can help refractory brick last up to 30% longer.

If workers find problems, they should fix them right away. Small cracks can be sealed. Big damage may need new bricks. Keeping up with checks and repairs helps avoid costly shutdowns and keeps everyone safe.

Taking care of refractory products helps them last longer. It also keeps equipment working well. Doing regular checks stops sudden problems. Workers should do these things to help refractory products last:

Store refractory products in dry places with good airflow. Water and sunlight can hurt bricks before they are used.

Keep packaging closed until you need the materials. Open them only when ready to use, and use them soon.

Use the oldest stock first. This stops bricks from getting old and losing quality.

Order new materials two or three months before you need them. This helps you get them on time and avoid waiting.

Talk to suppliers about your work plans and how things run. Good planning helps you get the right materials when you need them.

Check refractory linings often for cracks or damage. Finding problems early lets you fix them before they get worse.

Heat up and cool down equipment slowly. Fast changes in temperature can crack or break the lining.

Teach workers how to use and care for refractory products. Trained workers make fewer mistakes and help stop damage.

Write down all maintenance work. Keeping records helps you plan better repairs in the future.

Checking equipment often and planning shutdowns helps you find and fix problems. These steps help equipment last longer, save energy, and keep people safe. Good maintenance also saves money by fixing small problems before they get big.

Mistakes during installation or care can make refractory products wear out faster. This can cost a lot to fix. The most common mistakes are:

Picking materials just by looking at datasheets, not thinking about how they will be used.

Not matching the right refractory product with the right way to install it.

Using the wrong materials for the job or the way they are put in.

Not changing plans when things like fuel or production change.

Not thinking about all the work needed or what is expected.

Mixing materials the wrong way, like adding too much water or using the wrong tool.

Letting workers who are not trained or skilled do the installation.

Other mistakes are not cleaning surfaces well, skipping curing times, or using the wrong materials. Workers should always clean surfaces, follow curing steps, and pick the right refractory product for each job.

| Mistake | How to Avoid It |

|---|---|

| Poor surface preparation | Clean off dirt, oil, and other stuff |

| Ignoring curing times | Do what the manufacturer says |

| Incorrect mixing techniques | Use the right tools and steps |

| Wrong material selection | Ask experts and match to the job |

Planning ahead, training workers, and paying attention to details help stop these mistakes. Using the right refractory products and following good steps keeps equipment safe, works well, and lasts a long time.

Picking the right refractory bricks and putting them in the right way keeps equipment safe from high heat, rust, and damage. These bricks help save energy because they stop heat from escaping. They also keep furnaces safe to use. If bricks are not installed right, repairs can cost a lot and people could get hurt. For hard jobs, companies should hire experts who have special training like API 936 and know the rules for the job. Knowing about refractory products helps people make good choices, helps equipment last longer, and keeps everyone safer.

A Refractory Brick is a special kind of brick. It can handle very high heat and strong chemicals. Factories put it inside furnaces, kilns, and ovens. The brick keeps equipment safe from damage. It also helps save energy by holding in heat. People sometimes call it a fire brick.

People think about how hot the place will get. They also check if there are strong chemicals or heavy loads. High alumina bricks are good for steel plants. Acid bricks work well in chemical tanks. Always pick the Refractory Brick that fits the job best.

Tip: Talk to a supplier before you buy Refractory Brick.

Yes, people use Refractory Brick in their homes. It goes in fireplaces, wood stoves, and pizza ovens. The brick keeps heat inside and makes these places safer. Restaurants use it in baking ovens too.

Refractory Brick can last from one year to more than five years in factories. How long it lasts depends on the material, how it is put in, and how it is cared for. Checking and taking care of the brick helps it last longer.

| Application | Typical Lifespan |

|---|---|

| Furnace lining | 3–5 years |

| Fireplace | 5+ years |

Sometimes workers forget to clean the surfaces first. They might use the wrong kind of brick. Mixing the mortar wrong or skipping curing time can cause trouble. Trained workers and good planning help stop these problems.