Views: 0 Author: Site Editor Publish Time: 2025-08-19 Origin: Site

Refractory bricks are also called fire bricks. They are ceramic blocks that can handle very high heat. Factories use these bricks in furnaces and kilns. People at home use fire bricks in fireplaces and grills. These bricks resist heat very well. They last a long time and save energy. Fire bricks help protect equipment and buildings from harm. The market for refractory bricks is growing each year. In 2024, it is about 4.07 billion USD. By 2034, it may reach 6.10 billion USD.

| Year | Market Size (USD Billion) |

|---|---|

| 2024 | 4.07 |

| 2034 | 6.10 |

Refractory bricks are also called fire bricks. They can handle very high heat. They protect machines in factories and homes.

There are four main types of refractory bricks. These are acidic, basic, neutral, and special. Each type works for different heat and chemicals.

Fire bricks last a long time. They help save energy. They keep heat inside furnaces, kilns, and fireplaces.

You need to pick the right fire brick. Think about the temperature and chemicals. Also, check the brick’s strength and porosity.

Using the right fire bricks makes things safer. It lowers repair costs. It helps factories and homes work better.

Refractory bricks are special ceramic blocks. They can handle very high heat. People use them where normal bricks would fail. These bricks keep equipment and buildings safe from heat damage. Factories and homes use them for safety and to work better.

Refractory bricks have special physical and chemical traits. These traits make them different from regular bricks. They help the bricks last in tough places.

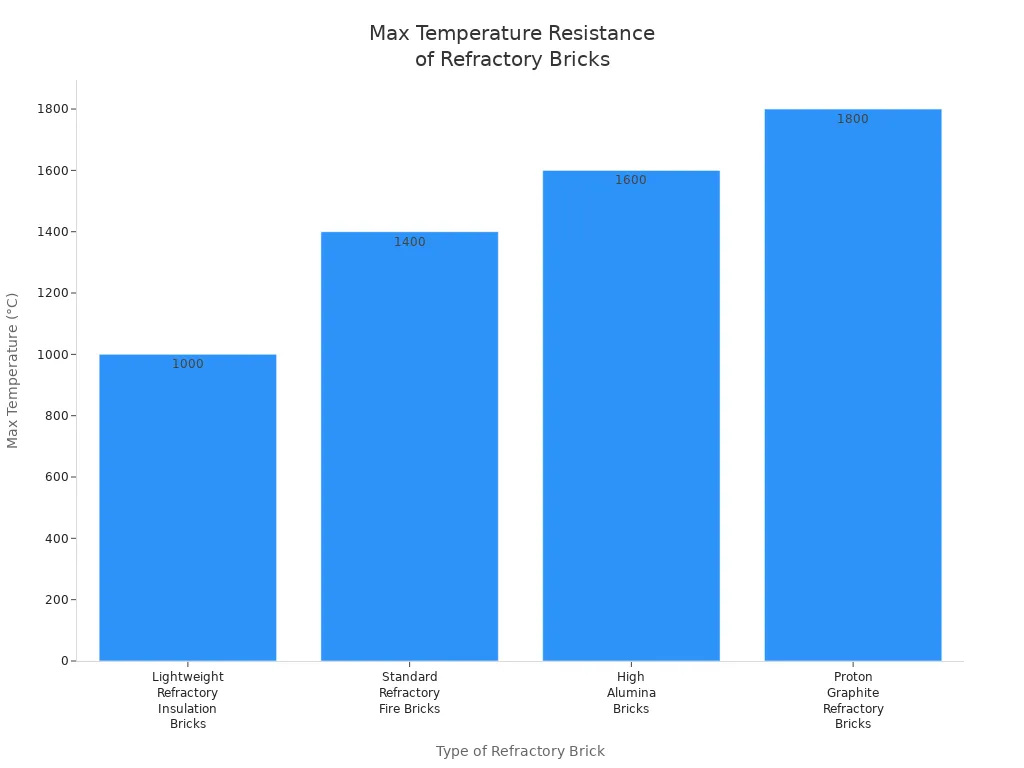

High Melting Point: Most refractory bricks can take heat from 500°C to 1800°C. Some, like high alumina or silicon carbide bricks, can take even more heat.

Strong Structure: They are strong and do not break easily under pressure.

Dimensional Stability: After being fired, these bricks keep their shape and size. This is called permanent linear change (PLC).

Resistance to Erosion: Refractory bricks do not wear out fast from heat, chemicals, or gases in furnaces and kilns.

Density and Porosity: How dense a brick is changes its strength and how it fights corrosion. Porosity means how many tiny holes are inside. Low porosity bricks are stronger and last longer. High porosity bricks insulate better.

Tip: The way fire brick is made controls its porosity and density. Picking the right materials and firing temperature helps get the best brick for each job.

Here is a table that shows how porosity changes the properties of refractory bricks:

| Property | Effect of Increased Porosity | Notes on Control and Application |

|---|---|---|

| Thermal Conductivity | Goes down because air pockets insulate | High porosity is good for insulating refractories |

| Mechanical Strength | Goes down because pores make it weaker | Dense bricks are better for holding weight |

| Corrosion/Erosion | More pores mean more exposure to harmful things | Low porosity helps bricks resist damage |

| Thermal Shock Resistance | Some porosity helps, but too much causes cracks | Porosity must be controlled for heating and cooling cycles |

| Application Examples | Low porosity for furnace tops; high porosity for insulation | Need balance for things like metallurgical ladles |

Refractory bricks are made from things like alumina, silica, magnesia, and sometimes silicon carbide. These materials give the bricks their high melting points and chemical strength. Making fire brick means mixing, shaping, and firing at high heat to make them strong and stable.

Different refractory bricks have different chemical makeups:

Clay bricks: 30%-48% alumina, used up to 1500°C.

High-alumina bricks: Over 48% alumina, used up to 1790°C.

Silica bricks: Over 93% silica, used above 1650°C.

Magnesia bricks: Over 80% magnesia, used above 2000°C.

Silicon carbide bricks: High SiC content, great for wear resistance and heat flow.

These traits let refractory bricks work well in furnaces, kilns, and other hot places.

Fire bricks and regular bricks look alike, but they are used for different things and have different traits.

| Brick Type | Main Composition Components | Key Mineral Phases / Characteristics |

|---|---|---|

| Refractory Bricks | Silicon-alumina, alumina, mullite, zirconia, silicon carbide, carbon compounds | High alumina content; mineral phases like corundum and mullite; may include silicon carbide or zirconium compounds |

| Ordinary Fire Bricks | Clay minerals, silica, glass phases | Lower alumina content; mainly mullite (25-50%), glass phase (25-60%), cristobalite and quartz (up to 30%) |

Composition: Fire bricks have more alumina, silica, or other special minerals. Regular bricks are mostly clay and sand.

Heat Resistance: Fire bricks can take heat up to 2700°F (about 1480°C) or more. Regular bricks start to crack and break at lower heat.

Thermal Conductivity: Fire bricks keep heat in and stop energy loss. Regular bricks lose heat faster.

| Brick Type | Thermal Conductivity (W/m·K) |

|---|---|

| Regular Brick | ~0.7 |

| Pumice Fire Brick | ~0.1 |

Durability: Fire bricks last longer in hot places. They do not crack, get attacked by chemicals, or break from quick temperature changes. Regular bricks wear out fast when they face heat, water, or chemicals.

Lifespan: In fireplaces or ovens, fire bricks last 5 to 10 years. In factories, they last 1 to 5 years, depending on use. Regular bricks do not last as long in these places.

Note: The way fire brick is made gives it strength and heat resistance for hard jobs. Regular bricks are not made the same way, so they cannot take high heat.

Refractory bricks have different types. Each type has its own chemicals and uses. The main groups are acidic, basic, neutral, and special bricks. People pick the right type for their needs.

Acidic refractory bricks fight off acids and acid slags. These bricks have lots of silica, usually more than 93%. Silica bricks and fire clay bricks are common kinds. They work well where acid gases or slags can hurt the lining.

Main Features:

Lots of silica (over 93%)

Resist acid damage

Handle high heat

Materials Used:

Silica (SiO₂)

Fire clay (aluminosilicate)

Where They Are Used:

Coke ovens

Glass furnaces

Furnace roofs

Chemical tanks and reactors

Chimneys and incinerators

Acidic refractory bricks keep equipment safe from acid. They last longer in places with acid gases or slags.

| Industry | Typical Applications |

|---|---|

| Chemical Industry | Reactors, tanks, pipes, acid pools |

| Metallurgical Industry | Coke ovens, blast furnaces, furnace roofs |

| Power and Energy | Desulfurization systems, absorption towers |

| Environmental Protection | Sewage pools, sedimentation tanks |

Yufeng Refractory makes silica bricks that are pure and strong against acid. Their bricks work well in glass kilns and coke ovens with high heat and acid slags.

Basic refractory bricks fight basic slags and high heat. These bricks have lots of magnesia (MgO) or lime (CaO). They do not break down with basic chemicals. Factories use them in steelmaking and cement kilns.

Main Features:

Lots of magnesia or dolomite

Resist basic slags and iron slags

High melting points

| Type of Basic Refractory Brick | Main Chemical Components | Key Characteristics |

|---|---|---|

| Magnesia Brick | MgO (80% to 85% or more) | Resist basic slag, used in furnaces and metal smelting |

| Dolomite Brick | CaO and MgO | Used in converters and furnace linings |

| Forsterite Brick | 2MgO·SiO₂ | Used in chambers and copper smelting |

Where They Are Used:

Steel blast furnaces

Cement kilns

Metal smelting

Power plant boilers

Basic refractory bricks keep furnaces safe from basic slags and heat. They help steel and cement plants work well.

Steel industry: Used in blast furnaces, converters, and ladles.

Cement industry: Line kilns and coolers.

Petrochemical industry: Used in reactors and reformers.

Yufeng Refractory makes magnesia and dolomite bricks for steel and cement plants. Their bricks are pure and handle high heat and basic slags.

Neutral refractory bricks stand up to acids and bases. They have alumina (Al₂O₃), chromite, or carbon. These bricks work well where chemicals change a lot.

Main Features:

Made from alumina, chromite, or carbon

Resist both acid and basic slags

Good thermal stability

| Raw Material Category | Examples / Specific Materials | Characteristics / Role in Neutral Refractory Bricks |

|---|---|---|

| Alumino-silicate Raw Materials | Fireclay, synthetic mullite | Chemical neutrality, thermal stability, resist slag and shock |

| High Alumina Raw Materials | Bauxite, fused alumina, sintered alumina | High strength, erosion resistance |

| Neutral Materials | Fused magnesia alumina spinel, silicon carbide | Chemical neutrality, thermal stability |

Where They Are Used:

Glass furnaces

Cement kilns

Steel refining furnaces

Places with changing chemicals

Neutral refractory bricks stay strong when chemicals change. They resist damage from acids and bases.

High alumina bricks: Used in blast furnaces, furnace roofs, and steel drums.

Chrome bricks: Used in glass furnaces and metal smelting.

Silicon carbide bricks: Used in kilns, incinerators, and reactors.

Yufeng Refractory makes high alumina and chrome bricks. Their bricks are strong and resist acid and basic slags. These bricks work well in glass, steel, and cement jobs.

Special refractory bricks have unique features for hard jobs. They use advanced materials like silicon carbide, corundum, or mullite. These bricks handle very high heat, quick heating and cooling, and strong chemicals.

| Special Refractory Brick Type | Composition / Raw Materials | Unique Properties | Temperature Resistance | Typical Applications |

|---|---|---|---|---|

| Bauxite Bricks | Calcined bauxites, refractory clays | Resist heat shock, good against slag | Up to 1600°C | Furnaces, kilns |

| Mullite Bricks | Special clays, high-alumina grogs | Low porosity, pure, stable | 1400-1600°C | High-temp linings, devices |

| Corundum Bricks | Synthetic alumina | Resist chemicals, up to 95% alumina | Up to 1700°C | Blast furnaces, refining |

| Silicon-Carbide (SiC) Bricks | High-purity silicon carbide | Strong, resist heat shock and wear | Up to 2800°C | Steelmaking, kilns, incinerators |

| Acid-Resistant Bricks | Clays with additives | Low porosity, resist chemicals | Not specified | Acid tanks, reactors |

Key Features of Silicon Carbide Bricks:

Handle heat up to 2800°C

Resist heat shock

Resist chemicals and wear

Move heat well

Last long and need less fixing

Where They Are Used:

Steelmaking: Tap holes, ladle linings, furnace troughs

Glass and ceramics: Kiln furniture, burner nozzles

Chemical jobs: Incinerators, reaction vessels

Energy: Waste-to-energy boilers

Silicon carbide bricks save energy and last longer in tough places. They keep furnaces and reactors safe and working well.

Yufeng Refractory makes silicon carbide, corundum, and mullite bricks. Their bricks help steel, glass, and chemical industries. These bricks handle high heat, quick changes, and strong chemicals.

Common Shapes and Sizes

Factories use many shapes and sizes of refractory bricks. The most common are straight, wedge, and corner bricks. Each shape fits a special part of a furnace or kiln.

| Type of Refractory Brick | Description / Shape | Typical Dimensions (mm) | Typical Industrial Use |

|---|---|---|---|

| T-Grade Straight Bricks | Rectangular bricks | T-3: 230 x 114 x 65 | Kilns, masonry, furnace lining |

| Thick Wedge Bricks | Axe-shaped bricks | T-19: 230 x 114 x 65/55 | Furnace doors, arches |

| Side and Rear Wedge Bricks | Knife-shaped, corner bricks | T-38: 230 x 114 x 65/55 | Arches, furnace doors |

| Corner-type Bricks | Special corner shapes | T-46: 275 x 230 x 150 x 80/15 | Corners of furnaces and kilns |

Picking the right type and shape of refractory brick keeps equipment safe and saves energy.

Summary Table: Types of Fire Bricks and Their Uses

| Type | Main Material(s) | Best For | Example Applications |

|---|---|---|---|

| Acidic Bricks | Silica, fire clay | Acidic places, acid slags | Coke ovens, glass furnaces |

| Basic Bricks | Magnesia, dolomite | Basic slags, high heat | Steelmaking, cement kilns |

| Neutral Bricks | Alumina, chromite, carbon | Acid and basic slags, changing conditions | Glass tanks, steel refining |

| Special Bricks | SiC, corundum, mullite | Extreme heat, wear, or chemicals | Blast furnaces, incinerators |

There are many types of fire bricks. Each type helps protect equipment and save energy. People pick the right brick to keep things safe and working well.

Factories use fire bricks to protect equipment. These bricks line furnaces, kilns, and reactors. They can handle very high heat and strong chemicals. Fire bricks are used in steelmaking, glass making, cement kilns, and chemical plants. The table below shows which industries use fire bricks most and why.

| Industry | Reason for High Fire Brick Consumption |

|---|---|

| Metallurgy | Needs fire bricks for hot steel and metal work. |

| Glass | Uses fire bricks to line kilns and furnaces for glass. |

| Ceramics | Depends on fire bricks for kiln building and heat control. |

| Cement | Uses fire bricks in kilns to handle heat and chemicals. |

| Others | Includes power plants, waste burning, and chemical jobs. |

Fire bricks protect machines by stopping heat up to 1800°C. They also block damage from chemicals. These bricks keep heat inside furnaces and help save energy. Insulating fire bricks lower fuel use and save money. They stop cracks and damage, so repairs happen less often.

Common Industrial Applications:

| Application | Description |

|---|---|

| Steel Production | Lines furnaces, resists heat and slag. |

| Glass Manufacturing | Handles quick heat changes and melted glass. |

| Chemical Processing | Protects reactors from chemical damage. |

| Power Generation | Lines boilers, helps keep heat in. |

| Kilns | Holds heat for making ceramics. |

| Incineration | Handles burning trash and high heat. |

Fire bricks help factories work safely and save energy. They keep machines strong and lower costs.

People use fire bricks in fireplaces, wood stoves, and grills. These bricks make fireplaces safer and work better. Fire brick can take heat over 1,800°F and does not crack. It has silica and alumina, which make it strong and tough.

Fire bricks protect walls and chimneys from heat.

They bounce heat back into the firebox, warming rooms.

Fire brick lasts longer than regular bricks, even with lots of heating and cooling.

Checking and fixing fire bricks keeps them working and stops heat loss.

Tip: Curing fire bricks before using them removes water and makes them stronger. This step helps stop cracks and keeps things safe.

Fire bricks make homes safer and help save energy. They keep fireplaces working well for many years.

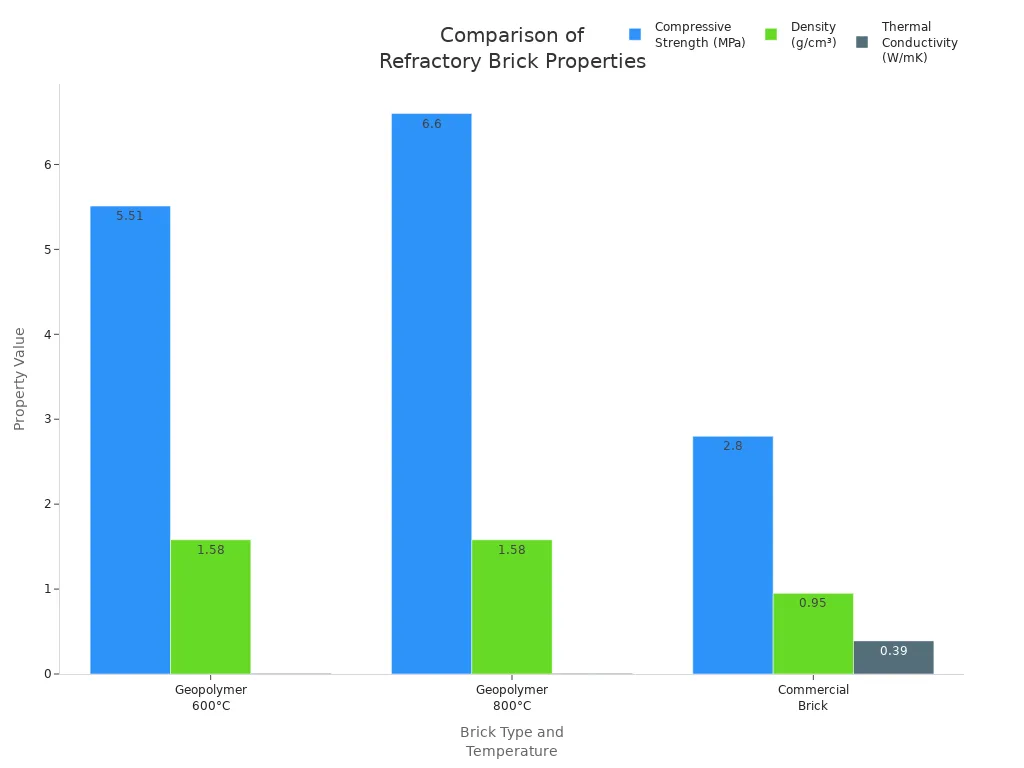

Refractory materials keep equipment safe from very high heat. They stay strong and do not change shape, even above 1800°C. Scientists tested different bricks to see how they work in heat. Geopolymer refractory bricks made with volcanic ash were stronger than regular bricks. They also did not let heat pass through as easily. This means they are better at stopping heat and keeping things cool.

| Property | Geopolymer Refractory Bricks (600°C) | Geopolymer Refractory Bricks (800°C) | Commercial Refractory Bricks |

|---|---|---|---|

| Compressive Strength (MPa) | 5.51 | 6.60 | 2.80 |

| Density (g/cm³) | 1.58 | 1.58 | 0.95 |

| Thermal Conductivity (W/mK) | 0.008 | 0.008 | 0.39 |

Another study looked at clay bricks with perlite. Adding perlite made the bricks better at stopping heat. But it also made them weaker. Geopolymer refractory materials are stronger and last longer than these other bricks.

Note: High heat resistance keeps furnaces, kilns, and fireplaces safe for a long time.

Refractory linings last a long time in tough places. This means less money spent on fixing or replacing them. Factories use brick refractory in rotary kilns because it can handle rough materials. It costs more to put in, but you save money later.

Strong refractory means fewer repairs are needed.

Brick linings stand up to heat and chemicals better than castable types.

Fixing bricks can be hard because they support each other.

Cracks and damage often happen from heating and cooling or chemical attacks.

Checking bricks and temperatures often helps them last longer.

Carbon refractory has gotten better with smaller pores and better graphitization. These changes help it fight off damage and last longer in blast furnaces. This also means less money spent on repairs.

Refractory materials help save energy when things get hot. Lighter linings stop more heat from escaping and use less fuel. In Europe, using lighter refractory in tunnel kiln cars saved up to 70% energy. They did not need to change the furnace or how it worked.

Insulating refractory keeps heat inside furnaces.

Low thermal conductivity and weight help heat up and cool down faster.

Linings that last longer protect equipment from heat damage.

Lower outside temperatures make work areas safer and cooler.

Tip: Using lighter refractory can also mean you need less heavy support, which saves money.

Industries like metallurgy, ceramics, and power plants save energy with refractory. These materials help factories work better and stay safe.

Picking the right refractory brick starts with knowing the job. Each furnace, kiln, or oven gets different heat and chemicals. Engineers check the highest temperature the equipment will reach. Fireclay bricks work up to 1600°C. Zirconia bricks can handle up to 2400°C. The chemical environment is important too. Acidic or basic slags can hurt some bricks. Magnesia bricks resist alkaline slags. Silica bricks are good for acidic places. The air inside the kiln, like oxidizing or reducing, affects how the brick works. Matching the brick’s chemical makeup to the job helps it last longer.

Tip: Always check the temperature and chemicals before picking a refractory. This stops early damage and keeps equipment safe.

Many things matter when picking refractory bricks. Here are the most important ones:

Temperature: Choose bricks that fit the highest heat.

Resistance: Find bricks that fight acids, alkalis, corrosion, and abrasion.

Porosity: Pick the right porosity for shock resistance and insulation.

Chemical Composition: Match the brick’s makeup to the job for longer life.

Cost: Balance cost and performance for the best value.

Other things to think about are thermal stability, bulk density, and electrical conductivity. Electric furnaces need insulating refractories. Bulk density changes heat storage and energy use. Lower density means less mass and better heat holding. How you install the bricks, like castables or precast shapes, changes how the lining works and cures.

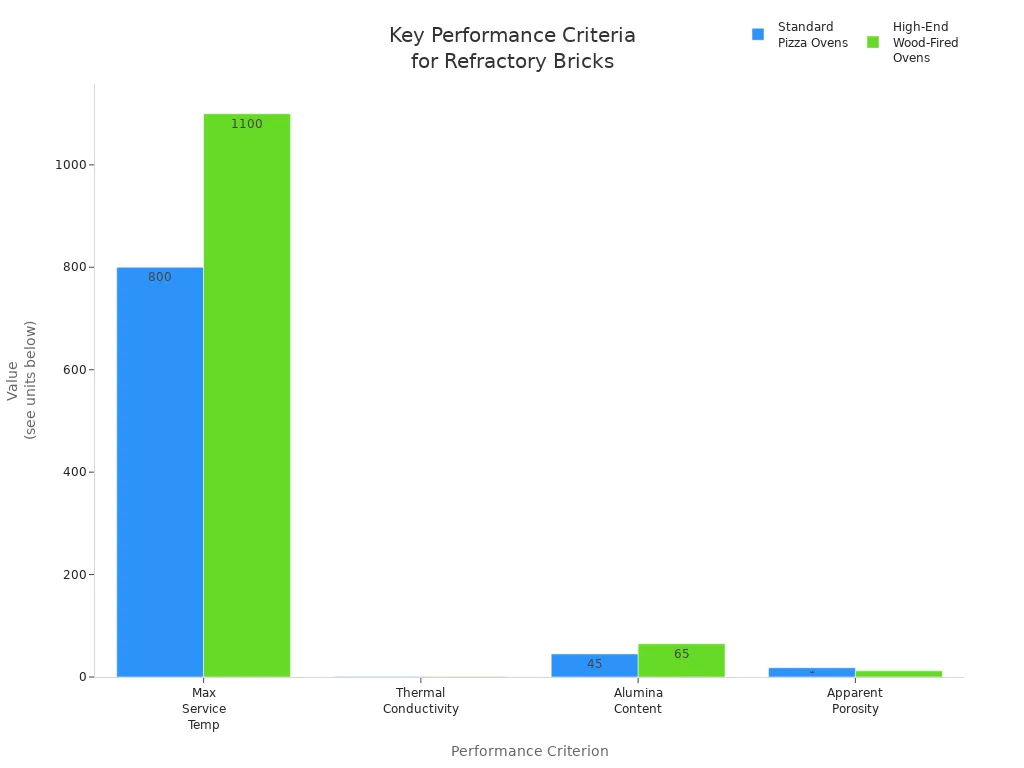

| Performance Criterion | Standard Pizza Ovens | High-End Wood-Fired Ovens |

|---|---|---|

| Maximum Service Temperature | Up to 800°C | Up to 1,100°C |

| Thermal Conductivity | 0.8–1.2 W/m·K | 0.6–1.0 W/m·K |

| Alumina (Al₂O₃) Content | 40–50% | 60–70% |

| Apparent Porosity | Less than 18% | Less than 12% |

Note: New ideas like self-healing and smart linings may make refractory bricks work better in the future.

Fire bricks protect equipment and buildings from extreme heat. They come in different types, each made for special jobs. People use fire bricks in factories and homes because they last long and save energy. Choosing the right fire bricks depends on the heat level and chemicals in each place. The best choice gives strong protection and keeps things working safely for years.

Refractory bricks use minerals like alumina, silica, magnesia, and sometimes silicon carbide. These minerals help the bricks stand up to high heat and chemicals. Factories pick the right mix for each job.

Refractory bricks can handle much higher heat than regular bricks. They also resist chemicals and sudden changes in temperature. Regular bricks break or crack when they get too hot. Refractory bricks keep furnaces, kilns, and fireplaces safe.

People use refractory bricks in fireplaces, wood stoves, pizza ovens, and grills. These bricks hold heat inside and protect walls from fire. Homeowners pick them for safety and saving energy.

Refractory bricks last for many years in homes and factories. How long they last depends on heat, chemicals, and care. Checking and fixing bricks helps them last longer.

Yes, people can cut refractory bricks using special saws or tools. Always wear safety gear when cutting. Cutting bricks helps them fit into ovens, kilns, or fireplaces.