Views: 0 Author: Site Editor Publish Time: 2025-08-26 Origin: Site

Refractory bricks are very important for protecting things from high heat. They are used in furnaces, kilns, and reactors. These bricks can handle very hot temperatures, strong chemicals, and heavy pressure. Knowing the difference between dense and insulating bricks helps companies save energy and work better. The way refractory bricks are made and what they are made of affects how well they work.

The worldwide market for refractory bricks was $4.07 billion in 2024. This is because iron, steel, cement, and glass industries are growing. Asia-Pacific has the biggest share of the market. The market will keep growing as more people use advanced insulating bricks.

| Aspect | Details |

|---|---|

| Market Size 2024 | USD 4.07 billion |

| Projected Market Size 2034 | USD 6.10 billion |

| Key Applications | Iron & Steel, Cement, Glass, Non-ferrous Metals, Petrochemical |

| Regional Market Leader | Asia-Pacific |

Refractory bricks keep equipment safe from high heat, chemicals, and pressure. They are used in places like steel, cement, and glass factories. Dense bricks are strong and heavy. They can handle direct flames and heavy weight. Insulating bricks are light and have lots of air pockets. These air pockets help keep heat inside and save energy. Insulating firebricks are a special kind of insulating brick. They hold heat very well and help lower fuel costs by stopping heat from escaping. The materials and additives in refractory bricks change how strong, heat-resistant, and long-lasting they are. Picking the right brick is important for each factory’s needs. Quality control during making sure the bricks are safe and work well. This helps factories work better and lowers repair costs.

Refractory bricks are special ceramic materials. They can handle very high heat, strong force, and chemicals. Makers use raw materials like alumina, silica, magnesia, or chrome compounds. These materials help the bricks stay strong and keep their shape in hot places like furnaces or kilns. Fire bricks are a type of refractory brick. They resist sudden changes in temperature and last a long time. These bricks protect equipment and buildings in tough conditions.

Many industries use refractory bricks for heating jobs. Steel and metal foundries put fire bricks in ladles, blast furnaces, and converters. These places get hotter than 1700°C. Cement and lime kilns use clay bricks and high alumina bricks. They work well between 1400°C and 1700°C. Power plants use fire bricks and silica bricks in boilers and incinerators. These can reach 1200°C. Oil and gas refineries need special refractory bricks like magnesite-chrome. These bricks can handle chemicals and high heat. Glass makers use high alumina fire bricks for melting tanks. These tanks get hotter than 1400°C.

Fire bricks keep things safe and help machines work well in hot places.

| Industrial Application | Common Refractory Brick Types | Operating Temperature Range |

|---|---|---|

| Steelmaking (blast furnaces, ladles, converters) | High alumina bricks, dense fire bricks | Up to and exceeding 1700°C |

| Cement and lime kilns | Clay bricks, high alumina bricks | Around 1400°C to 1700°C |

| Power plants (boilers, incinerators) | Standard fire bricks, silica bricks | Up to 1200°C |

| Oil and gas refineries (FCC units, reformers) | Specialized bricks (e.g., magnesite-chrome) | High temperature, basic refractory needs |

| Glass manufacturing (melting tanks) | High alumina bricks, fire bricks | High temperature, typically above 1400°C |

| Non-ferrous metallurgical processes | Basic refractory bricks (chrome-magnesite, magnesite-chrome) | High temperature, slag resistant |

Dense bricks are very important in hot factories. Makers use alumina, silica, and magnesia to make them. They heat and press these materials together. This makes the bricks strong and heavy. Dense bricks do not break easily from heat or chemicals. They are used inside furnaces, kilns, and reactors. These bricks touch flames, melted metals, and hot liquids. Their tough build helps them last a long time.

Factories use dense bricks in steel furnaces and glass tanks. They also use them in rotary kilns and aluminum smelters. These bricks keep machines safe from heat and damage. High alumina bricks have almost all alumina. They can stand heat above 1500°C. Silica bricks have lots of silicon dioxide. They work well in acid places like coke ovens. Magnesia bricks have magnesium oxide. They are good for cement kilns and steelmaking.

| Property | Dense Refractory Bricks |

|---|---|

| Thermal Conductivity | ≥ 1.0 W/m·K (at ~350°C) |

| Density | > 2.0 g/cm³ |

| Mechanical Strength | High |

| Refractoriness | > 1400°C (up to 1900°C) |

| Typical Use | Direct flame contact, structural |

Dense bricks are the first layer in most furnaces. They protect against heat, wear, and chemicals. These bricks hold heat inside but let some escape. If there is no insulation, energy can be lost.

Insulating bricks help keep heat inside furnaces. They are made from silica, alumina, and fireclay. Makers use special ways to make them full of tiny holes. These holes trap air and make the bricks light. Insulating bricks do not carry heat well.

These bricks do not hold heavy things or touch flames. They go behind dense bricks as a second layer. Their job is to stop heat from leaving the furnace. This saves energy and keeps the inside warm. Less heat escapes, so fuel use goes down.

Factories put insulation bricks in furnaces, kilns, and boilers. They also use them in chimneys and reactors. These bricks work from 500°C to 1400°C. They are light and easy to move. This makes building cheaper and faster.

Note: Insulation bricks help save energy. They keep heat inside and protect the furnace walls.

| Property | Insulating Bricks |

|---|---|

| Thermal Conductivity | 0.2 - 0.4 W/m·K (at ~350°C) |

| Density | 0.8 - 1.0 g/cm³ |

| Mechanical Strength | Lower than dense bricks |

| Refractoriness | < 1400°C |

| Typical Use | Thermal insulation, secondary lining |

Insulation bricks are used in steel, ceramics, and glass factories. They are also used in chemical plants and power stations. These bricks help keep heat even, make better products, and lower costs.

Insulating firebricks are a special kind of insulation brick. They have lots of tiny holes inside. Makers add things to make these holes during making. This makes the bricks light and good at stopping heat. Insulating firebricks use pure clay and alumina. They are baked at high heat to set their shape.

Insulating firebricks have many good points:

They do not let heat pass through easily.

They are light and easy to cut and shape.

They heat up and cool down fast.

| Property/Feature | Insulating Firebricks (IFBs) Characteristics | Comparison to Dense Bricks |

|---|---|---|

| Porosity | High porosity (>45%) | Dense bricks have low porosity |

| Density | Low density, lightweight | Dense bricks are heavy and dense |

| Thermal Conductivity | Low, excellent insulation at >1000°C | Dense bricks have higher thermal conductivity |

| Mechanical Strength | Relatively low, not suitable for load-bearing or work lining | Dense bricks have high mechanical strength |

| Resistance to Wear/Erosion | Poor resistance to erosion and wear | Dense bricks are abrasion resistant |

| Workability | Soft and easy to cut and shape | Dense bricks are hard and difficult to cut |

| Application | Used as insulating layers in kilns and high-temperature equipment (>1000°C) | Dense bricks used as thermal mass and work lining |

Insulating firebricks cannot hold heavy things or touch flames. They go behind dense bricks as insulation. Dense bricks take care of wear and chemicals. Insulating firebricks stop heat from escaping and save energy.

Factories use insulating firebricks in kilns and furnaces above 1000°C. They help save energy by holding less heat and using less fuel. These bricks heat up and cool down quickly. This helps machines work faster.

Tip: Insulating firebricks help dense bricks last longer. They protect against sudden heat changes.

Dense bricks and insulating bricks do different jobs. Dense bricks are strong and face heat and chemicals. Insulating bricks and firebricks go behind dense bricks. They keep heat inside and save energy.

| Feature | Dense Bricks (Primary Lining) | Insulating Bricks / IFBs (Secondary Lining) |

|---|---|---|

| Function | Structural, abrasion-resistant | Thermal insulation, heat retention |

| Thermal Conductivity | High | Low |

| Mechanical Strength | High | Lower |

| Placement | Direct contact with heat | Behind dense bricks |

| Energy Efficiency | Moderate | High |

Insulating bricks and firebricks are very useful in factories. They trap heat, save energy, and help companies spend less money. Their light weight makes building easier and cheaper.

Thermal resistance is very important for refractory bricks. It shows how well a brick can stop heat in hot places. Engineers use different ways to measure this property. They look at thermal conductivity, thermal shock resistance, and pyrometric cone equivalent (PCE). The table below lists the main ASTM standards and what they are used for:

| Metric / Property | ASTM Standard(s) | Description / Application |

|---|---|---|

| Thermal Conductivity | C201-24, C202-19, C182-24, C767-24, C1113/C1113M-09 | Ways to measure thermal conductivity in different refractory types |

| Thermal Shock Resistance | Work of fracture (WOF), fracture toughness (KIC) | Checks how well bricks resist cracks from heating and cooling |

| Pyrometric Cone Equivalent (PCE) | Seger cones, ASTM-related test | Tests how much heat bricks can take before softening |

Dense bricks can handle high heat and keep their shape. They also work well under flames and heavy weight. These bricks let heat move through them faster. Insulation bricks, like insulating fire bricks, do not let heat pass as quickly. This helps keep the outside of furnaces cooler. Insulating fire bricks are great for saving energy as a second layer.

The way insulation bricks resist heat depends on what they are made of. Insulating fire bricks have lots of tiny holes that trap air. Air stops heat from moving through the brick. This makes them good at keeping heat inside. In factories, using bricks with low thermal conductivity helps keep temperatures steady and saves energy.

Insulation performance tells us how well a brick keeps heat from escaping. Insulating bricks, especially insulating fire bricks, are very good at this. Makers give these bricks many small holes inside. These air pockets slow down heat and lower thermal conductivity. Because of this, insulating fire bricks are better at keeping heat in than dense bricks.

Special ways of making bricks create even pores.

Even pores trap air and slow down heat.

Some new bricks have tiny pores for very low thermal conductivity, even as low as 0.05 W/m·K.

The holes help the bricks stay strong and keep their shape at high heat, making them last longer.

Insulation bricks usually have thermal conductivity between 0.05 and 0.3 W/m·K. Lower numbers mean better insulation. Dense bricks have higher numbers and do not insulate as well. Insulating fire bricks are best when you need to save energy and keep heat in.

Note: The holes in insulating fire bricks help keep heat in and make the temperature inside furnaces and kilns steady.

Durability means how long refractory bricks last in tough places. In steel plants, refractory linings can last from 12 to 36 months. This depends on heat, chemicals, and stress. Insulation bricks, like insulating fire bricks, wear out less because they are not in direct contact with flames or heavy loads. This helps them last longer.

Many things affect how long insulation bricks last:

Fast heating and cooling can cause cracks.

Shaking or wrong placement can damage bricks.

Chemicals from slag or ash can harm the surface.

Good installation and care help bricks last longer.

Dense bricks are strong and do not let chemicals in easily. They last longer against wear and attack. Insulation bricks last a long time if used right. Good insulating fire bricks balance holes and strength for both durability and insulation.

Chemical stability means bricks can resist damage from harsh chemicals. Insulation bricks with lots of alumina are good at fighting acids, alkalis, and melted metals. The table below shows what helps bricks stay strong and last longer:

| Feature | Contribution to Chemical Stability and Durability |

|---|---|

| High Alumina Content | Gives great heat and chemical resistance, helping bricks survive in tough furnace conditions. |

| Precision Manufacturing | Makes sure bricks are even and strong, so there are fewer weak spots for chemicals to attack. |

| Resistance to Wear, Erosion, and Chemical Corrosion | Helps bricks last longer by stopping damage from chemicals and wear. |

| Optimized Thermal Conductivity | Keeps heat spread out evenly, which lowers stress and helps chemical stability. |

Insulating fire bricks with few holes stop harmful liquids from getting inside. This keeps the bricks from being damaged by chemicals. Some bricks are made to fight acids or alkalis even better. Bricks with silicon carbide or spinel are extra strong against acids and melted metals. These bricks are good for chemical plants, glass furnaces, and other tough places.

Insulating fire bricks have many good points for factories. Their low thermal conductivity and high insulation save a lot of energy. Some new bricks, like EcoFoam insulating fire bricks, use tiny holes to stop heat from moving in all ways. This keeps heat even and stops hot spots, making furnaces work better.

Insulating fire bricks have lots of air pockets, which do not carry heat well.

More holes mean better insulation but can make bricks less strong.

The best bricks balance holes and strength for good insulation and support.

Using insulation bricks as a second layer helps factories use less fuel and spend less money. Insulating fire bricks also heat up and cool down fast, which helps control the process and saves time. They are light, so they are easy to put in and do not make furnace walls heavy.

Tip: Picking the right insulation bricks and insulating fire bricks for each job helps equipment last longer and work better.

Insulating fire bricks are important because they do not let heat pass easily, keep heat in, and resist chemicals. They help factories save energy and work better, which is good for the environment.

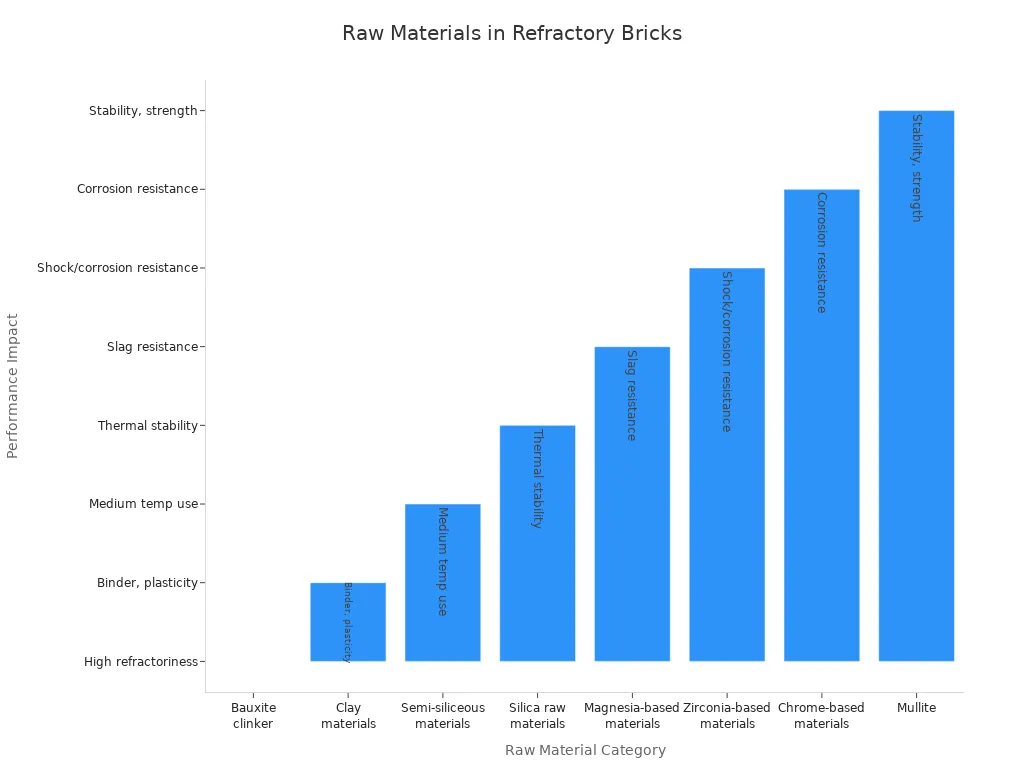

Manufacturers pick raw materials for refractory bricks based on how they need to work in hot places. The most common ones are fireclay, bauxite, magnesia, silica, and special minerals like zirconia and mullite. Each material gives the brick different strengths. Fireclay is easy to shape and melts together well. Bauxite has lots of alumina, so it can handle more heat. Magnesia and chrome-based materials help the brick fight off slag and corrosion. Special things like synthetic mullite and refractory fibers make the brick stronger and steadier.

| Raw Material Group | Examples / Types | Chemical Nature / Composition | Performance Characteristics and Applications |

|---|---|---|---|

| Siliceous Raw Materials | Vein quartz, quartzite, flint, sandstone | High SiO2 content, low impurities | Used in silica bricks for glass furnaces, coke ovens; high refractoriness |

| Fireclay Raw Materials | Hard clays, soft clays, clay shales | Kaolinite-based, refractoriness >1580°C | Core for alumino-silicate refractories; good plasticity and sintering |

| Basic Raw Materials | Magnesia (magnesite), dolomite | MgO and CaO rich, alkaline | Used in steelmaking linings; good slag resistance and thermal stability |

| Zirconia-Based Raw Materials | Zircon, baddeleyite, zirconia-mullite composites | ZrO2 rich, chemically inert, low thermal conductivity | Enhances thermal shock resistance, corrosion resistance, and density |

| Chrome-Based Raw Materials | Chromite | Cr2O3 rich, corrosion resistant | Used in chrome bricks for non-ferrous metallurgy and incinerator linings |

| Specialty and Synthetic | Synthetic mullite, industrial alumina, refractory fibers | Tailored properties for advanced applications | Improve strength, thermal shock resistance, and chemical stability |

Insulating firebrick uses special additives to keep heat from passing through and to stay strong. Makers add sawdust or rice husk to the mix. These burn away when the brick is fired, leaving tiny holes that trap air and slow down heat. Ceramic fibers and mineral wool make the brick stronger and help it stay steady in heat. Lightweight clays, alumina, and silica fill in gaps to help the brick keep its shape and handle heat. Binders hold everything together before firing. If you use about 15% sawdust, the brick will insulate well and be strong enough for furnace walls.

Sawdust and rice husk make more holes, so the brick insulates better.

Ceramic fibers and mineral wool make the brick stronger and steadier.

Alumina and silica fillers help the brick handle heat and stay tough.

Binders keep the mix together before firing.

Tip: Using the right mix of additives in insulating firebrick helps keep heat in and makes the brick strong enough for factories.

What goes into refractory bricks changes how well they stand up to heat, chemicals, and wear. More alumina helps the brick handle quick changes in heat but can make it less able to fight off corrosion. Corundum bricks have lots of alumina, so they are strong and resist alkali corrosion. Magnesia-chrome bricks are great at fighting slag and staying steady in steelmaking. Mullite and the right amount of holes in insulating firebrick help keep heat from escaping and let the brick handle quick temperature changes. Bricks with few holes, like andalusite-based ones, stop melted stuff from getting in, so they resist corrosion better.

| Refractory Brick Type | Chemical Composition / Key Phases | Impact on Thermal Shock Resistance | Impact on Corrosion Resistance | Additional Notes |

|---|---|---|---|---|

| High Alumina Bricks | Contain mullite | Good thermal shock resistance | Poor corrosion resistance | Not suitable under high temperature and alkali metal concentration |

| Corundum Bricks | Corundum crystal structure | High volume stability | Good alkali corrosion resistance | Absorbs alkali metal ions between layers |

| Magnesia-Chrome & Chrome-Corundum Bricks | High refractoriness, chromium content | Good thermal shock resistance (varies by bonding) | Good alkali and slag erosion resistance | Chromium toxicity concerns |

| Calcium Aluminate Bricks | Calcium aluminate phases | Excellent stability in reducing atmospheres | Good corrosion resistance in alkaline environments | Compatible with aluminum products |

| Magnesia Alumina Spinel Bricks | Stable spinel structure | Low thermal conductivity, small thermal expansion | Strong alkali corrosion resistance | High strength and impact resistance |

| Composite Bricks (e.g., Zirconium Corundum) | Composite phases including zirconium corundum | Good thermal shock stability | Good acid corrosion resistance | Good erosion and wear resistance |

| Aluminum-Carbon Bricks | Aluminum and carbon phases | Used in reducing atmospheres | Resist alkali corrosion by slowing corrosion process | Prevent embrittlement and damage |

| Aluminosilicate Bricks | Alumina and silica with mullite, corundum | Depends on porosity and microstructure | Corrosion resistance varies; andalusite bricks have higher resistance due to low porosity | Bonding system and phases affect strength and corrosion |

Note: Insulating firebrick with the best mix of additives and raw materials keeps heat in, handles quick temperature changes, and works well in tough factory jobs.

Makers pick materials for insulating bricks very carefully. They want bricks that can take high heat and not break. The bricks must also stop heat from getting out.

Insulating bricks can work in furnaces up to 1,760°C (3,200°F). They do not fall apart at these high temperatures.

Dense microstructures and special chemicals make bricks last longer. These things help bricks not crack or get hurt by chemicals.

Using materials with low thermal conductivity keeps surfaces cool. This also saves energy.

When picking materials, makers think about:

How much heat the brick can take.

How well the brick keeps heat inside.

If the brick can be made in special shapes and sizes.

If the brick is strong and lasts a long time.

These choices help keep workers safe and machines working well. They also make sure the bricks last a long time in factories.

The way bricks are shaped changes how they work. Makers mix pure refractory clays with things like sawdust. They use different ways to shape the bricks:

Dry pressing squeezes dry powder hard to make strong bricks.

Extrusion pushes wet clay through a shape to make hollow bricks.

Casting or hand molding pours wet clay into molds for special shapes.

Each way makes the brick’s holes, weight, and strength different. Drying the bricks right after shaping stops cracks. Shaping is important for making bricks that insulate well and last long.

Firing makes bricks strong and gives them their final form. Makers heat bricks from 850°C to 1,200°C. Firing can take 5 hours at lower heat or 2 hours at higher heat.

| Parameter | Details / Values |

|---|---|

| Firing Temperatures | 850°C (Class-B), up to 1,200°C (for higher strength and porosity) |

| Firing Duration | 5 hours at 850°C; 2 hours at 1,200°C |

| Bulk Density | ≤ 0.90 g/cm³ (Class-B) |

| Porosity | ≥ 60% (Class-B) |

| Cold Crushing Strength | ≥ 1.47 MPa |

| Thermal Conductivity | ≤ 0.35 W/m·K at 600°C |

Things like sawdust or polystyrene burn away during firing. This leaves holes that help the brick insulate better. Changing the amount of grog or filler changes how strong or full of holes the brick is. Smoother bricks from casting keep heat in better. Rougher bricks from extrusion let more heat out. These steps help bricks meet tough rules for strength and saving energy.

Quality control checks that every batch of bricks is good.

Workers test what the bricks are made of and how heavy they are.

They check how many holes are in the bricks and how well they stop heat.

They test how much weight the bricks can take before breaking.

They measure if the brick changes size after firing.

They look at how much water the brick soaks up and how the holes are spread out.

Samples are tested using careful steps to make sure results are right.

Quality control also checks if all the binder burned away and if everything mixed well. Cooling the bricks slowly makes them stronger. These steps stop problems, keep people safe, and make sure the bricks work well and last a long time in tough jobs.

There are many kinds of refractory bricks. Each type is made for a special job in hot places. Insulating bricks are good at keeping heat inside. They help save energy and lower repair costs. Engineers must think about how hot the bricks can get. They also look at how well the bricks resist chemicals, how strong they are, and how much they cost.

Picking the right brick keeps workers safe. It helps machines work well and last longer in tough factories.

Insulating bricks keep heat inside furnaces and kilns. They help stop heat from escaping. This saves energy and protects machines from getting too hot. Many factories use these bricks to work better and spend less on fuel.

Insulating bricks have lots of tiny holes filled with air. These holes make the bricks light and good at stopping heat. Dense bricks are heavy and strong. They are made to touch flames and hold up heavy things.

Insulating bricks with lots of alumina can fight acids and alkalis. Makers add special minerals to make them even stronger against chemicals. These bricks work well in places with harsh chemicals, like glass and chemical factories.

Makers mix clay, alumina, and things like sawdust together. They shape the bricks and bake them at high heat. The sawdust burns away and leaves air pockets. These pockets help the bricks insulate and make them lighter.

Insulating bricks are light and easy to cut or shape. Workers can put them in furnaces or kilns quickly. Their low weight helps finish building faster and saves on labor costs.