Views: 0 Author: Site Editor Publish Time: 2025-08-27 Origin: Site

You use a refractory brick when you need something strong in high heat. This fire brick does not melt or wear out from chemicals. It is important for furnaces, kilns, and pizza ovens. There are different types of refractory bricks. Some are silica, high alumina, magnesite, and carbon-based. Each type has special features for certain jobs. People use them in steelmaking and glass production. Picking the right refractory material keeps things safe and working well at work or at home.

Refractory bricks like fire brick, high alumina, silica, and basic bricks all have special features for high heat and chemicals.

You need to pick the right brick based on your furnace’s temperature, chemical contact, and how fast it heats or cools.

Fire bricks are strong and can handle heat well, so they work well in furnaces, kilns, and pizza ovens.

High alumina bricks last longer and do hard jobs in steel, cement, and glass factories.

Always check bricks for good quality and install them the right way to keep your furnace safe and save energy.

Fire brick refractory has a lot of alumina and silica. These minerals make the bricks strong and able to handle heat. Makers add small amounts of other oxides like Fe2O3, TiO2, CaO, Na2O, and K2O. Even tiny bits of alkali oxides can lower how much heat the brick can take. This can make the brick work less well in hot furnaces. Some companies use special additives to help the bricks form better. They must be careful with these additives. The chemical makeup of fire brick refractory affects how it deals with heat, stress, and chemicals.

Tip: When picking fire brick refractory, look at alumina and silica levels. More alumina means the brick can handle more heat and slag.

Fire brick refractory can stand very high temperatures. These bricks have high melting points because of their crystal structure. They are strong and do not wear out easily. Low porosity and high density help stop liquids and gases from getting in. This makes the bricks last longer in tough places. The alumina layer keeps the brick safe from corrosion. The empty spaces inside help the brick deal with quick changes in heat. Most fire bricks are 230×144×65 mm, but there are special shapes too. Insulating firebricks are light because they have lots of pores. They are good for keeping heat in kilns.

| Property | Description |

|---|---|

| High Temperature | Can handle up to 1790°C |

| Mechanical Strength | Strong against pressure and wearing down |

| Chemical Resistance | Stays safe from slag and chemicals |

| Thermal Shock Resistance | Handles fast changes in temperature |

| Low Porosity | Stops liquids and gases from getting inside |

Fire brick refractory is used in many industries. It works well in places with high heat. Steel plants, glass factories, chemical plants, and power stations use these bricks. You also see fire brick refractory in furnaces, kilns, incinerators, and reactors. At home, people use fire brick in fireplaces and pizza ovens. The bricks keep heat inside and do not get damaged by flames or hot gases. They last a long time and protect places that get very hot.

Common uses for fire brick refractory:

Furnace linings in steel and glass plants

Kiln walls in ceramics and cement production

Fireplaces and pizza ovens for home and commercial use

Incinerators and boilers in power plants

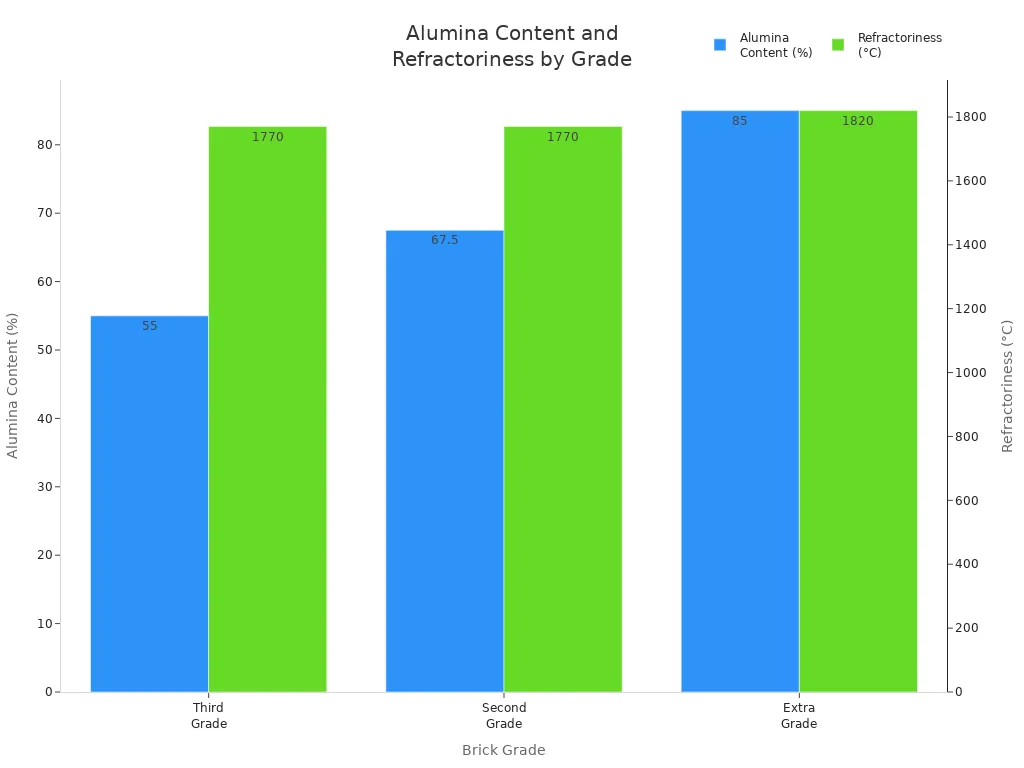

High alumina refractory bricks are made from bauxite or synthetic alumina. These bricks have a lot of alumina, which makes them strong and heat-resistant. The amount of alumina can be from 55% to over 90%. If there is more alumina, the brick works better in hard jobs. Sometimes, makers add other minerals to make the bricks even better.

| Grade | Alumina Content (Al₂O₃) | Refractoriness (°C) | Key Properties and Applications |

|---|---|---|---|

| Third Grade | ≥55% | ~1770 | Neutral refractory, high thermal stability, good slag resistance, used in hot work kilns |

| Second Grade | 60-75% | 1770 | Better slag resistance, improves furnace service life, widely used in hot work kilns |

| Extra Grade (Special) | >85% | 1820 | Highest refractoriness, twice service life of ordinary bricks, excellent thermal shock stability and slag resistance |

When you look at the table, you see that more alumina means the brick can handle more heat and chemicals.

High alumina refractory bricks are special because they stay strong in high heat. You can use them where other bricks might break. These bricks do not get damaged by slags or gases. They keep their shape even when it is very hot and heavy things are on them. The bricks do not wear out fast.

Note: High alumina bricks are stronger and last longer than clay bricks. But they do not handle quick temperature changes as well as some other bricks.

These bricks let some heat pass through, but not too much. This helps furnaces and kilns save energy and last longer. Some bricks, like phosphate-bonded or micro-expansion types, have extra features for special jobs. You should pick the right grade for your needs.

| Property | High Alumina Brick | Andalusite Brick |

|---|---|---|

| Composition | Bauxite or synthetic alumina (>48% Al2O3) | Natural andalusite (Al2SiO5), converts to mullite |

| Thermal Refractoriness | Excellent (≥1550°C) | Excellent (up to 1700°C) |

| Thermal Shock Resistance | Good | Superior due to mullite formation |

| Creep/Sag Resistance | Moderate under load | Lower creep rate at high temperatures |

| Density & Mechanical Strength | Dense (~2.5–3 g/cm³), strong | Slightly lighter, retains high strength |

| Slag & Chemical Resistance | Excellent | Excellent, enhanced by mullite presence |

| Thermal Stability | Performs well in steady high-temperature environments | Better resistance to rapid thermal changes and thermal cycling |

| Industrial Applications | Blast furnaces, petrochemical, power plants | Steel ladles, tundishes, electric arc furnaces, glass manufacturing |

| Cost | Lower cost, widely available | More expensive, justified by performance |

High alumina refractory bricks are used in many places that need to handle high heat. These bricks line blast furnaces, rotary kilns, and electric furnace roofs. The steel industry uses them the most for furnace linings and ladles. Cement plants use them in rotary kilns because they last longer and save energy. Glass factories and petrochemical plants also use these bricks for hot jobs.

Main uses for high alumina refractory bricks:

Steel and metal industry: blast furnaces, ladles, kilns

Cement production: rotary kiln linings

Glass manufacturing: glass melting furnaces

Petrochemical industry: reactors, incinerators

Power generation: boilers, incinerators

These bricks help the lining last longer and keep heat inside. Using them in hot places saves energy and keeps things safe. When you need bricks for tough, hot jobs, high alumina types are a great choice.

Silica refractory bricks are made from quartzite or quartz. Makers crush these minerals and press them into shape. Then, they fire the bricks at very high heat, between 1400°C and 1500°C. The silica in these bricks is very pure, about 99.5%. When the bricks are fired, the quartzite turns into special crystals. These crystals are called tridymite and cristobalite. They help the bricks stay strong and stable in hot places. The high amount of silica is important for how the brick works. This makes silica refractory bricks a popular choice for many jobs.

Silica refractory bricks have special thermal and chemical features.

These bricks have more than 93% silica, so they work in very hot places.

Their true density is about 2.33 to 2.35 g/cm³, and they soften between 1620°C and 1670°C.

They do not change shape much, even after long use in heat.

You can pick different densities, like 0.6, 0.8, or 1.0 g/cm³, for insulation.

These bricks are stable and last a long time, so they do not melt or break easily.

Their porosity is between 17% and 25%, and bulk density is 1.8 to 1.95 g/cm³.

Silica refractory bricks resist acid and can handle quick temperature changes, but their thermal shock stability is low.

Making these bricks is good for the environment, with no NOx or CO2 released.

Tip: Silica refractory bricks help save energy and last longer in tough places, so they are a smart pick for hot jobs.

Silica refractory bricks are used in many places that need strong, heat-proof linings.

Here is a table that shows where you can find these bricks:

| Industry | High-Temperature Processes / Equipment Using Silica Bricks |

|---|---|

| Glass Industry | Glass-melting furnaces (masonry roofs, parapets, hanging walls, flow channels) |

| Iron and Steel | Blast furnaces, converters, electric arc furnaces, continuous casting equipment |

| Petrochemical | Cracking furnaces, catalytic units, refining units |

| Coke Ovens | Various parts of coke ovens |

| Hot Blast Furnaces | Regenerative upper parts, combustion chambers |

| Electric Arc Furnaces | Linings in electric arc furnaces |

In glass factories, silica refractory bricks can last up to 15 years if cared for well. They move heat well and do not get damaged by chemicals. This makes them great for glass kilns, coke ovens, and hot blast furnaces. You can trust these bricks to work well and help save energy in your job.

Magnesite bricks are used where strong fire resistance is needed. These refractory bricks are made mostly from magnesia (MgO). Makers heat them to very high temperatures, between 1550°C and 1600°C. The bricks are dense and can handle a lot of heat. Magnesite bricks work well with basic slags and in hot places. They do not have chromium oxide, so they are best where there is less chemical attack. Magnesite bricks have small amounts of iron oxide and alumina. These do not change how the bricks work. You can trust these bricks in steelmaking and cement kilns.

| Component | Magnesite Bricks (Typical) | Magnesia-Chrome Bricks (Typical) |

|---|---|---|

| Magnesia (MgO) | High content, primary component providing refractory properties | 45-65% (varies by grade) |

| Chrome Oxide (Cr2O3) | Negligible or none | 8-16% (acts as stabilizer and improves corrosion resistance) |

| Impurities | Minor, depending on raw materials | Small amounts of Fe2O3, Al2O3 depending on manufacturing |

Chrome refractory brick is also called magnesia-chrome brick. It is made by mixing magnesia with chromite ore. This brick has 8% to 16% chromium oxide (Cr2O3). Chromium oxide makes the brick stronger against chemicals and heat. Makers fire these bricks at even higher temperatures, up to 1850°C. Chromium oxide helps form special minerals like periclase and chromium spinel. These bricks are very dense and used where slags and molten metals are harsh. They do not corrode easily and last longer in tough places. The strong structure helps them work well in steel and glass furnaces.

Tip: Pick chrome refractory brick if you need more protection from chemicals and high heat.

Basic refractory bricks are used in many industries. Magnesite bricks are good for cement kilns and steel furnaces. Chrome refractory brick and dense chromium oxide bricks are best for very tough jobs. They can handle molten metals, slags, and chemicals. You see them in refining, incineration, chemical, and petrochemical plants. These bricks also line rotary cement kilns, glass furnaces, and electric furnace walls. They are used in places like melter sidewalls, bottoms, and near bubblers. Their strength and low heat transfer help them last longer. They work well where there is a lot of erosion and quick temperature changes.

Common uses for basic refractory bricks:

Metallurgical furnaces and electric furnace tops

Rotary cement kiln burning zones

Glass furnace regenerative chambers

Chemical and petrochemical reactors

Incineration plant linings

Dense chromium oxide bricks are best for the hardest jobs. They give the best fire resistance and chemical strength. Using these bricks helps you stop breakdowns and keep your lining working longer.

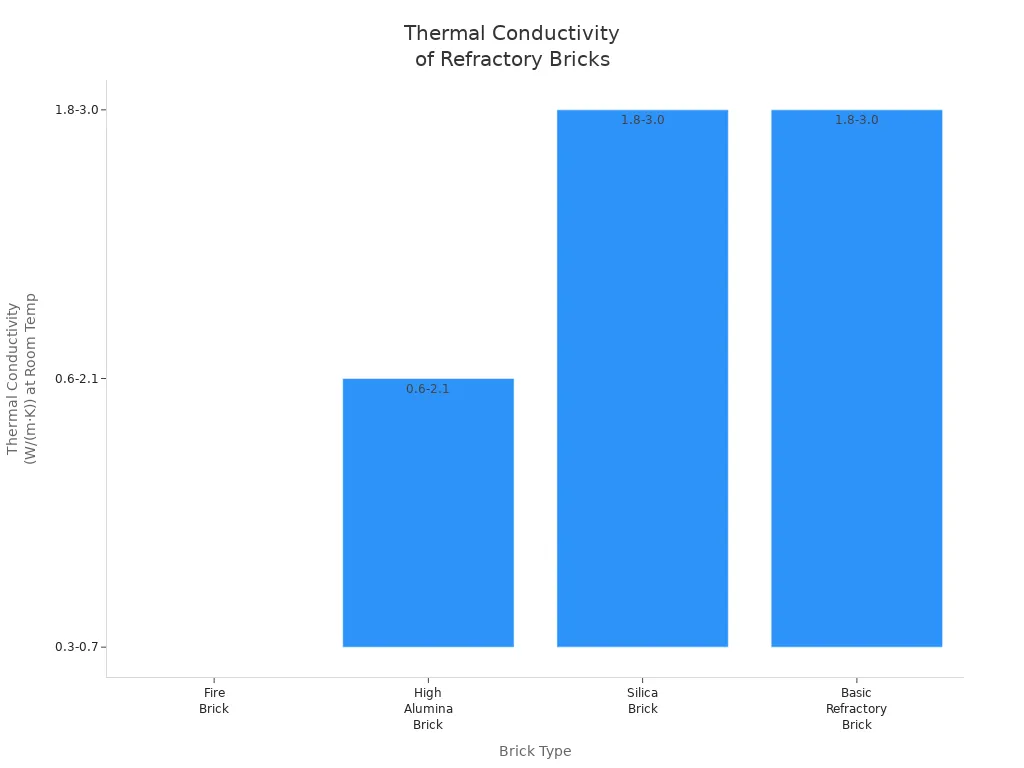

When you pick refractory bricks, you should know how each one works. Every brick type has special features for certain jobs. The table below shows how fire brick, high alumina, silica, and basic refractory bricks are different. Chrome bricks are included too.

| Brick Type | Main Composition | Max Service Temp (°C) | Thermal Conductivity at Room Temp (W/(m·K)) | Chemical Resistance | Durability (Years) | Cost per Ton ($) | Typical Applications |

|---|---|---|---|---|---|---|---|

| Fire Brick (Fireclay) | Alumina, Silica | 1,400–1,790 | 0.3–0.7 | Good (acidic/neutral) | 7–15 | 1,200–2,000 | Furnaces, kilns, fireplaces, pizza ovens |

| High Alumina Brick | Bauxite, Al₂O₃ | 1,770–1,820 | 2–3× fire brick (drops at high temp) | Excellent (neutral) | 7–15 | 1,500–2,500 | Steel, cement, glass, petrochemical |

| Silica Brick | Quartzite, SiO₂ | 1,620–1,670 | 1.8–3.0 | Excellent (acidic) | 10–15 | 1,800–2,500 | Glass furnaces, coke ovens, hot blast stoves |

| Basic (Magnesite) Brick | MgO | 1,800–2,000 | 1.8–3.0 | Excellent (alkaline) | 10–20 | 2,000–3,000 | Steel, cement, glass, chemical reactors |

| Chrome (Magnesia-Chrome) | MgO, Cr₂O₃ | 1,800–2,000 | High | Superior (alkaline/acidic) | 10–20 | 2,500–3,500 | Harsh chemical, glass, steel, incinerators |

High alumina bricks let more heat pass at room temperature than fire bricks. When it gets hotter, high alumina bricks lose some of this ability. At over 1000°C, they act more like fire bricks. Silica bricks also let heat move through easily, and this gets stronger as it gets hotter. Basic bricks, like magnesite and chrome bricks, let heat move fast because they are very dense.

How a brick is made and what it is made from changes how it holds or moves heat. High alumina bricks have lots of mullite and corundum crystals. These help them stay strong and not wear out in heat. Silica bricks have more tridymite and fewer holes, so they move heat well. This is good for glass furnaces where steady heat is needed.

If you look at cost and how long they last, firebricks can last 7–15 years if you use good bricks and mortar. Basic bricks, like magnesia-carbon types, can last up to three times longer than some castable materials in tough places. But these bricks cost more because they use special materials and need more work to make.

Firebricks are tough and do not wear out fast, even when things hit or rub them a lot. Castables are another kind of refractory material. They cost less but do not last as long and take more work to put in.

If you want to save energy, bricks with lower thermal conductivity, like fire bricks, keep heat inside better. This helps save energy and money. Bricks that let heat move fast, like silica and basic bricks, are good for some factories but not always for saving energy.

You should also think about the environment. Carbonless magnesia-alumina bricks help the planet more than MgO-C bricks. They cut climate change and water use by over half. But MgO-C bricks use less energy to make. You have to choose what matters most—using less energy to make the brick or helping the environment more.

Picking the right refractory bricks can be tricky, but you can do it if you follow some easy steps. Here are some tips to help you choose the best brick:

Check the Operating Temperature

Make sure the brick can handle the hottest part of your furnace or oven. Always pick a brick that softens at a higher temperature than you need.

Think About Chemical Resistance

Find out what slags, gases, or melts will touch the brick. Use magnesite or chrome bricks for alkaline places. Pick silica bricks for acidic slags. High alumina bricks work well in neutral or mixed spots.

Test for Thermal Shock Resistance

If your furnace heats up and cools down fast, pick bricks that can handle quick changes. Fire bricks and some high alumina bricks are good for this.

Check Mechanical Strength and Wear Resistance

If your process has lots of movement or things hitting the bricks, use bricks that are strong and dense. Firebricks and basic bricks are good choices.

Look at Thermal Conductivity

For saving energy, use bricks that do not let heat out easily. Fire bricks are best for this. If you need heat to move through, like in glass furnaces, pick silica or basic bricks.

Balance Cost and Lifespan

Good bricks cost more but last longer. Firebricks and basic bricks last the longest in hard jobs. Castables cost less but may not last as long.

Consider Environmental Impact

If you want to help the planet, look for carbonless bricks. These bricks use less water and help stop climate change.

Tip: Always test your refractory bricks before you use them. Check for holes, density, and how much pressure they can take. Good bricks have few holes, are heavy, and can handle lots of pressure.

Do not think all refractory bricks are the same. Each one is made for a different job.

Do not pick bricks just by reading datasheets. You need to know what your process needs and what the brick will face.

Do not forget to check if new bricks match the old ones in your furnace. Mixing the wrong bricks can cause cracks and damage.

Do not skip cleaning the surface before you put in new bricks. Dirty surfaces make bricks fall off.

Do not hire people who do not know how to install bricks. Bad installation makes bricks break sooner.

You should follow industry rules to make sure your bricks last. Test for holes, how much water they take in, how heavy they are, and how much pressure they can take. Take random samples from each batch. Check the size, weight, and look for cracks or other problems. Dry samples at 110°C before you test them. Use at least three samples for each test.

What is the hottest temperature in your furnace?

What chemicals or slags will touch the brick?

Does your process heat up or cool down fast?

Do you want to save energy or move heat quickly?

How much money do you have for materials and work?

Do you want to help the environment?

Have you tested your bricks for quality?

Note: If you are not sure which brick to pick, ask a supplier or expert. Tell them about your furnace, your process, and what you need. This helps you avoid mistakes and keeps your furnace working well.

If you know the main differences and follow these tips, you can pick the right refractory bricks for your job. This keeps your furnace safe, saves energy, and helps your work go smoothly. Picking the right brick also helps your lining last longer and saves you money. Remember, the best use of refractory bricks depends on matching the brick to your needs.

You now know that fire brick, high alumina, silica, and basic bricks are all different. Each type is good for certain jobs. Picking the right brick for your furnace or kiln keeps things safe. It also helps your work run better.

Always look at the heat, chemicals, and how you will put the bricks in before you choose.

If you want the best outcome, ask a supplier or expert for help. They can help you find a brick that lasts longer and saves you money.

You use fire brick for strength and heat resistance. Insulating fire brick keeps heat inside and saves energy. Insulating fire brick feels lighter and has more pores. You pick it when you want to keep heat in your furnace or oven.

You check the highest temperature your furnace reaches. You look at what chemicals or slags will touch the brick. You also think about how fast your furnace heats up and cools down. Ask a supplier if you feel unsure.

Yes, you can use insulating fire brick in a pizza oven. It keeps heat inside and helps your oven stay hot longer. You get better cooking results and save fuel. Make sure you use the right grade for food safety.

Refractory bricks can last from 7 to 20 years. The lifespan depends on the type of brick, how you use your furnace, and how well you install the bricks. Good care and regular checks help bricks last longer.

Yes, you need special refractory mortar. Regular mortar cannot handle high heat. Refractory mortar keeps bricks in place and stops heat from escaping. Always use the right mortar for your bricks and furnace.