Views: 0 Author: Site Editor Publish Time: 2025-08-19 Origin: Site

High alumina bricks are a kind of fire brick. They are made mostly from bauxite and other alumina-rich materials. Factories use these bricks in places with very high heat. Regular fire bricks might not work well there. High alumina bricks are special because they can take more heat. They also resist chemical damage better than regular fire bricks or other Refractory Bricks. Many factories pick them to line furnaces, kilns, and reactors. The table below shows how different industries use high alumina bricks:

| Industry | Usage/Application | Market Share/Importance |

|---|---|---|

| Steel Industry | Blast furnaces, ladles, high-temp units | Largest consumer |

| Cement Industry | Rotary kiln linings, high-temp equipment | Second largest |

| Glass Industry | Glass melting furnaces | Significant, growing |

| Non-ferrous Metals | Furnace linings | Important, growing |

| Others | Industrial furnaces, kilns, incinerators | Contribute significantly |

These bricks are very important for high-heat jobs. They help where fire bricks alone are not enough.

High alumina bricks have at least 48% alumina. This makes them very strong. They can handle heat above 1770°C.

These bricks do not get damaged by chemicals. They can handle quick changes in temperature. They last longer than regular fire bricks.

Factories use high alumina bricks in steel, cement, glass, and power plants. They protect furnaces and help save energy.

High alumina bricks are better than fire bricks. They resist heat better. They are stronger and more stable with chemicals. They work well for hard jobs.

Using high alumina bricks means fewer repairs. It makes things safer. It helps factories work better.

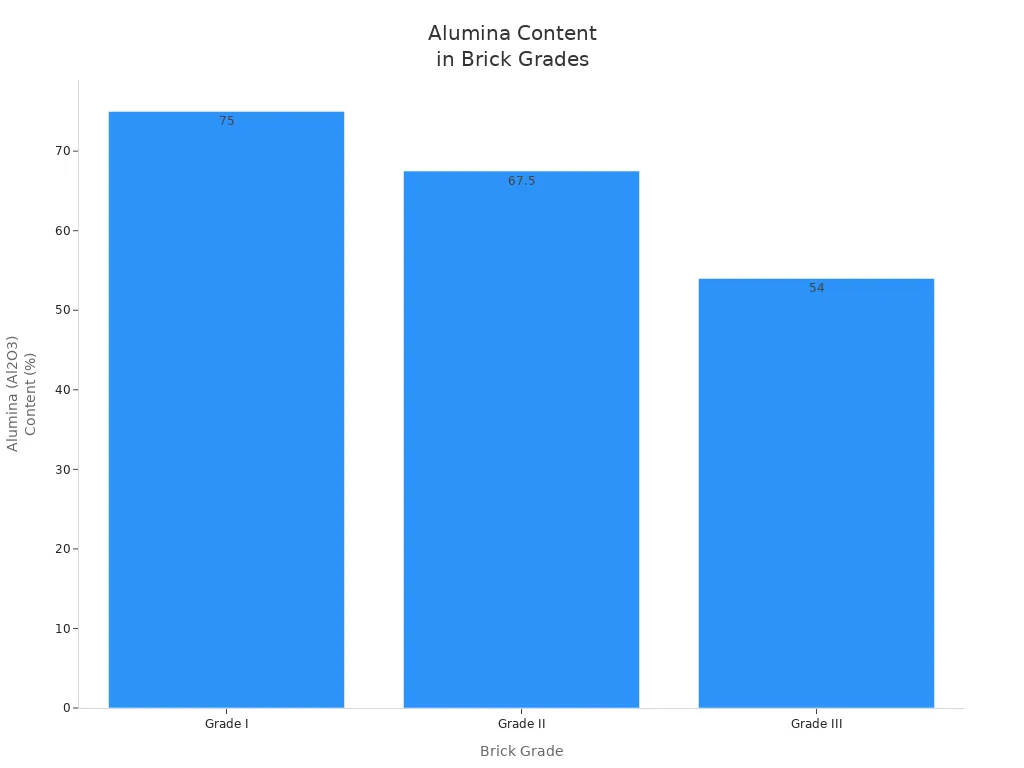

High alumina bricks are a type of refractory brick. They have a lot of alumina inside. The alumina content must be at least 48%. There are three grades based on how much alumina is in them:

Grade I has more than 75% alumina.

Grade II has 60% to 75% alumina.

Grade III has 48% to 60% alumina.

High alumina bricks need to be strong and the right size. They must have low amounts of iron oxide and silicon oxide. Tests check their density, porosity, and how much water they take in. These bricks can handle sudden heat changes and stay strong in tough places.

The table below shows the grades and how much alumina they have:

| Grade | Alumina (Al2O3) Content (%) | Description |

|---|---|---|

| Grade I | > 75 | Highest alumina content |

| Grade II | 60 - 75 | Medium alumina content |

| Grade III | 48 - 60 | Lower alumina content, still high alumina |

High alumina bricks can take heat above 1770°C. They do not melt or break down easily. They are strong and do not get damaged by acid or slag. This is why many industries use them.

High alumina bricks are made from special materials. The main one is bauxite, which has a lot of alumina. Bauxite has minerals like diaspore, boehmite, and gibbsite. When heated, these minerals turn into corundum and mullite. These crystals make the bricks strong and heat-resistant.

Other important materials are:

Fused alumina

Sintered alumina

Synthetic mullite

Kyanite group minerals (kyanite, andalusite, sillimanite)

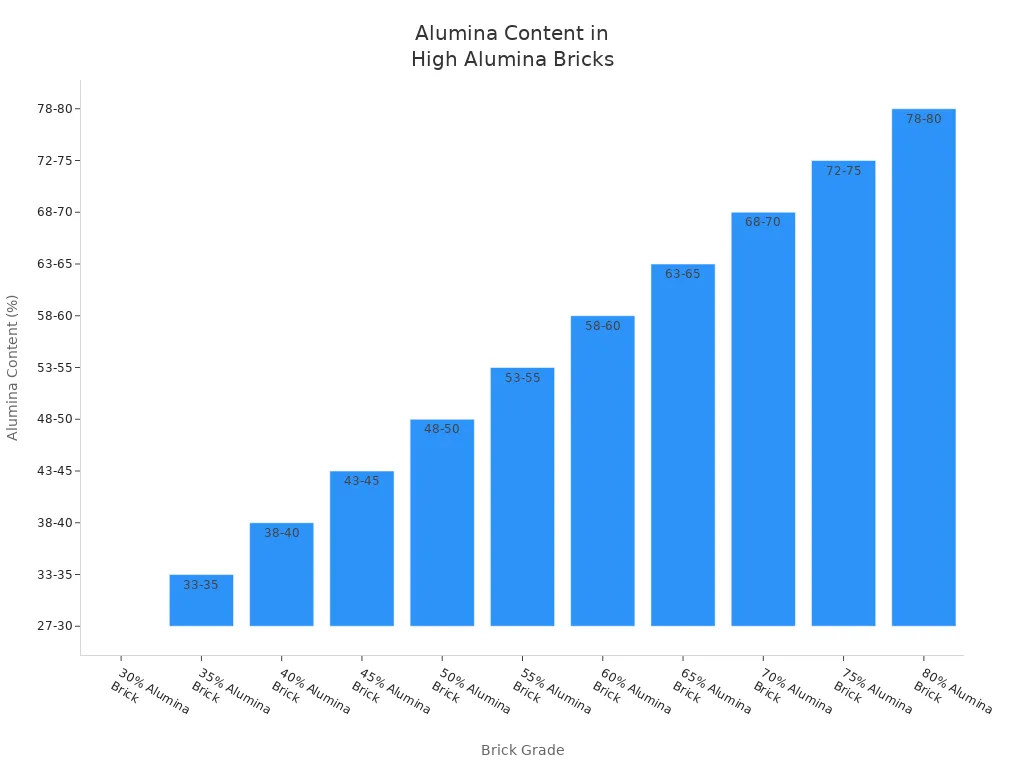

Manufacturers mix these materials and shape them. Then they fire them at high heat. This makes the bricks dense and not very porous. Finished bricks have 48% to over 90% alumina.

The table below shows alumina content in different bricks:

| Grade of Brick | Alumina Content Range (%) |

|---|---|

| Fire Clay Refractory Bricks | 25 - 50 |

| High Alumina Refractory Bricks | 50 - 90 |

| Corundum Bricks | > 90 |

Note: Bricks with more alumina work better in hot and harsh places.

High alumina bricks have many good features. These features make them useful for tough jobs.

High Temperature Resistance: They can take heat above 1770°C. They stay strong even when it is very hot.

Strong Mechanical Strength: These bricks do not break or crush easily. They keep their strength in hard jobs.

Excellent Chemical Stability: They do not get damaged by acids, alkalis, or slags. This helps them last longer in places with harsh chemicals.

Good Thermal Shock Resistance: Fast temperature changes do not crack these bricks. Their special mix helps them handle heating and cooling.

Low Porosity: They do not soak up much water. This makes them last longer.

Cost-Effectiveness: High alumina bricks last longer than many other bricks. This means you do not have to replace them as often.

Versatile Applications: Many industries use these bricks. They are used in steel, glass, cement, and power plants. They work well in each place.

The table below compares high alumina bricks to other bricks:

| Feature | High Alumina Bricks | Other Refractory Bricks |

|---|---|---|

| Alumina Content | >48% (up to >90% for corundum) | Lower alumina content |

| Refractoriness | Above 1770°C | Often lower |

| Corrosion Resistance | Good against acids and alkalis | Usually less resistant |

| Thermal Shock Resistance | Strong | Often weaker |

| Mechanical Strength | High at elevated temperatures | Lower at high temperatures |

| Typical Applications | Steel, glass, cement, power plants | Varies, less suited for harsh settings |

| Cost-Effectiveness | High due to long service life | May require more frequent replacement |

High alumina bricks are strong, stable, and can take a lot of heat. These things make them a top pick for many jobs.

High alumina bricks are better than many other bricks for tough jobs. Their special mix and features help them work well where other bricks cannot.

Refractory bricks and fire bricks both protect machines from heat. But they are not the same. High alumina bricks, regular refractory bricks, and fire bricks have different chemicals inside. These differences change how they work in hot places.

The table below shows how their chemicals and uses are not the same:

| Brick Type | Alumina (Al2O3) Content | Mineral Composition | Acid-Base Nature | Key Characteristics and Uses |

|---|---|---|---|---|

| High Alumina Bricks | >48% | Corundum, Mullite, Glass phases | Neutral to Alkaline | High thermal stability, better slag resistance, used in blast furnaces, kilns, and harsh environments. |

| Fire Clay Bricks | 30% - 40% | Mullite, Glass phase, Cristobalite, Quartz | Acidic (weak acid refractory) | Good thermal properties, resistant to acid slag and gas, less resistant to alkalis. |

| Standard Refractory Bricks | Varies widely (includes silica-alumina, magnesia, carbon, zirconium bricks) | Varies depending on type | Varies | Properties depend on use; alumina content and acid-base nature change with type. |

High alumina bricks have more alumina than fire bricks. This makes them stronger in heat and better against slag and rust. Fire bricks, also called fireclay bricks, have less alumina and more silica. They fight acid slag and gas but do not do well with alkalis.

Standard refractory bricks come in many types. Some have lots of silica, some have magnesia, and some have carbon or zirconium. Their features change with the minerals inside. For example, silicon carbide refractory bricks are strong and do not wear out fast. They are good for places with lots of rubbing.

How these bricks work in heat is also different. The table below compares high alumina bricks and fire bricks:

| Property | High Alumina Bricks | Fire Bricks (Fireclay) |

|---|---|---|

| Aluminum Oxide (Al2O3) Content | ≥ 55% | 30-55% |

| Bulk Density (g/cm³) | 2.3 - 2.5 | 1.8 - 2.3 |

| Refractoriness (°C) | 1690 - 1730 | 1750 - 1790 |

| Refractory Under Load (RUL) | Higher, less prone to shrinkage and deformation | Lower, more prone to shrinkage and deformation |

| Thermal Shock Resistance | Lower due to higher corundum content | Better thermal shock resistance |

| Chemical Stability (pH) | Neutral, stable in acidic and basic environments | More acidic, less stable in alkaline conditions |

High alumina bricks are better at stopping heat and chemicals. They do not shrink or bend much when heavy things press on them. Fire bricks can handle quick heat changes better, but they may not last as long with strong chemicals.

Note: Silicon carbide refractory bricks are very tough and strong. They are great for furnaces and kilns where things rub a lot.

Heavy-duty high alumina bricks have more alumina and are very fireproof. They are best for the hottest parts of a furnace. Lightweight high alumina bricks have more holes and are lighter. They help keep heat in but do not touch the hottest spots.

Different refractory bricks have different jobs in factories. High alumina bricks, fire bricks, and other standard refractory bricks each have their own best uses.

High Alumina Bricks:

Used in blast furnaces, hot blast stoves, and electric furnace tops.

Line rotary kilns and molten steel ladles.

Used for furnace tops, walls, and checkerwork in special chambers.

Used in reverberatory furnaces and storage bricks for flat furnaces.

Picked for furnaces that run hot for a long time. Their low creep rate keeps them strong and stops the lining from falling.

Stand up to gas and dust, so they are good for tough places.

Fire Bricks (Fireclay Bricks):

Used in easier parts of furnaces and kilns.

Found in fireplaces, pizza ovens, and small ovens.

Used as backup linings or insulation in big furnaces.

Handle quick heating and cooling well, so they work in places with lots of temperature changes.

Used in incinerators and chimneys where it is not too hot.

Standard Refractory Bricks:

Include silica-alumina bricks, magnesia bricks, carbon bricks, and zirconium bricks.

Silica-alumina bricks are used in coke ovens and glass furnaces.

Magnesia bricks fight off basic slags in steelmaking.

Carbon bricks work in electric arc furnaces at high heat.

Zirconium bricks stop chemical damage in glass and chemical factories.

Silicon carbide refractory bricks are used in kilns and furnaces with lots of rubbing, like waste burners and some glass furnaces.

Tip: The kind of fire brick you pick depends on heat, chemicals, and how much stress there is in each part of the furnace.

The list below shows where each brick is used most:

High alumina bricks: blast furnaces, hot blast stoves, electric furnace roofs, rotary kiln linings, molten steel ladles, and checkerwork in special chambers.

Fire bricks: fireplaces, pizza ovens, incinerators, chimneys, and as insulation in big furnaces.

Standard refractory bricks: coke ovens, glass furnaces, steelmaking furnaces, and chemical reactors.

Silicon carbide refractory bricks: kilns and furnaces with lots of rubbing, like waste burners and some glass furnaces.

Each brick has a special job. High alumina bricks last longer in hot, rough places. Fire bricks cost less and are good for places with less heat or lots of heating and cooling. Standard refractory bricks, like silicon carbide refractory bricks, are picked for special jobs where their features are needed.

Remember: Picking the right refractory brick helps furnaces last longer, saves money, and keeps factories safe.

Refractory brick can handle very hot temperatures. High alumina bricks are a type of refractory brick. They can resist heat up to 1800°C (3,272°F). Fireclay and kiln fire bricks only go up to 1500°C or 1600°C. The table below shows how much heat each brick can take:

| Brick Type | Maximum Temperature Resistance |

|---|---|

| High Alumina Bricks | Up to 1800°C (3,272°F) |

| Fireclay Bricks | 1500°C to 1600°C |

| Kiln Fire Bricks | 1500°C to 1600°C |

High alumina bricks have 45% to 99% alumina. This helps them stand up to more heat. They keep their shape and strength in flames. Many factories use these bricks in furnaces and kilns. They do not break when it gets hot. They also handle quick changes in temperature well.

High alumina bricks help keep machines safe from heat. They make factories work better and safer.

Refractory brick needs to be strong for tough jobs. High alumina bricks are very strong, even when hot. Their strength depends on the grade and alumina amount. The table below shows how strong each grade is:

| Grade / Alumina Content | Approximate Compressive Strength (MPa) |

|---|---|

| Special Grade (≥80% Al2O3) | ~80 - ≥100 |

| Grade I (75%-80% Al2O3) | ~70 - ≥85 |

| Grade II (60%-75% Al2O3) | ~60 - ≥70 |

| Grade III (55%-60% Al2O3) | ~50 |

These bricks do not crack or break easily. They can hold up heavy things and take fast heating. Their strength helps furnaces and kilns stay safe. Factories use them in places that need strong bricks.

Refractory brick also needs to fight off chemicals. High alumina bricks do not get damaged by acids or alkalis. Their alumina-silica mix protects them from molten alkali and slag. This makes them good for glass furnaces, cement kilns, and steel plants.

In factories, these bricks face strong chemicals and melted metals. Their chemical stability helps them last longer. Factories do not need to replace them often. This saves time and money.

High alumina bricks are great because they resist heat, are strong, and fight chemicals. These features make them important for hard jobs in factories.

High alumina bricks need special raw materials. These materials have lots of alumina and few impurities. Factories pick them for their purity. The main sources are:

Calcined bauxite has high alumina and low impurities. Chinese bauxite like GLM RD-88 and GLM-90 is used a lot. Guyanese bauxite is also very pure and has good alumina.

Brown fused alumina is picked because it is hard and stable.

Diaspore clay comes mostly from South Central Missouri in the United States.

Alumina-silicate minerals include kyanite, sillimanite, and andalusite.

These materials help bricks stand up to heat and chemicals. The quality of each material changes how the brick works. More pure alumina makes bricks stronger and better with heat. If there are impurities like iron oxide or alkali oxides, the bricks do not last as long.

Note: Factories must choose and check raw materials carefully. This helps high alumina bricks meet tough rules for factories.

Making fire brick, especially high alumina bricks, takes many steps. Each step helps the bricks work well in hot places.

Preparation and Sorting: Workers get raw materials ready. They sort bauxite, clay, and alumina. Then they grind and screen them to get the right size.

Mixing and Formulation: The materials are mixed with binders and additives. Water is added to make the mix even.

Molding: The mix is shaped into bricks. Factories use molds, extrusion, or pressing machines.

Drying: The bricks are dried to take out water. This stops cracks and problems.

Firing: Bricks are fired in kilns at 1350°C to 1600°C. This makes the bricks strong and able to take heat.

Quality Inspection: Workers check the bricks for density, porosity, and strength.

Making fire brick controls things like alumina content, porosity, and crushing strength. These things show how well bricks work with heat and pressure.

| Parameter | Importance |

|---|---|

| Alumina Content | Shows how well bricks resist heat and slag |

| Apparent Porosity | Changes insulation and how long bricks last |

| Cold Crushing Strength | Tells how much weight bricks can hold |

| Refractoriness Under Load (RUL) | Shows if bricks stay strong when hot |

| Thermal Shock Resistance | Tells if bricks crack with fast temperature changes |

Steel plants use high alumina bricks for very hot jobs. These bricks line blast furnaces, ladles, converters, and electric arc furnaces. They must handle heat above 1800°C. Bricks with 90% alumina stop corrosion and slag from hurting the lining. This keeps the furnace safe from chemical damage. Their strong strength helps them hold up heavy steel parts. Low porosity and high density keep melted metal and gas out. This makes the lining last longer.

High alumina bricks help stop cracks and breaks when heat changes fast.

Steel plants get longer use, less downtime, and fewer repairs.

One study showed furnace linings lasted 30% longer with these bricks.

Using them saves money and helps use less energy.

Steel makers pick these bricks for the hottest and most important spots.

Cement and glass factories use high alumina bricks in kilns and furnaces. These bricks can take heat over 1500°C and do not lose their shape. They are tough and do not wear out fast. This stops cracks and breaks. High alumina bricks also fight off damage from sulfur, alkali, and other harsh chemicals in cement and glass making.

Their low thermal conductivity keeps heat inside and saves energy.

The bricks’ insulation means less fuel is needed and helps the environment.

They last longer than fire bricks, so repairs happen less often.

New ways of making them, like phosphate bonding, make them even stronger and better with heat changes.

High alumina bricks help cement and glass kilns work well and are a top pick for these hot jobs.

Power plants use high alumina bricks to line boilers and protect from heat, slag, and chemicals. These bricks work well in special boilers that burn coal or plants. Mullite-based high alumina bricks do not wear down fast and fight off alkali damage. Anti-spalling bricks stop cracks and keep the structure safe.

High alumina bricks line the burning chambers, furnace walls, and gas pipes.

Their heat stability and strength keep the plant safe from breaking.

Plants saw a 40% longer lining life and 12% less heat loss after using 75% alumina bricks.

Repairs are needed less often, and costs go down when the right bricks are used.

Power plants trust high alumina bricks to work well in tough jobs.

High alumina bricks are very tough in hard places. They last longer than many other materials in hot spots. How long they last depends on how you put them in and take care of them. Most of the time, these bricks last from 1 to 5 years in factories. If you install them well and check them often, they can last up to 10 years. Many things change how long they last, like how often the furnace heats up and cools down, how hot it gets, and what chemicals are there.

High alumina bricks usually last 1–5 years.

With good care, they last 5–10 years.

Their life depends on heat, stress, and chemicals.

Good building and careful heating/cooling help them last longer.

Bad handling can make them last only a few months.

Tip: Check the bricks often and install them right to help them last longer.

High alumina bricks help save money over time. Their high alumina lets them handle over 300 quick temperature changes without breaking. This means you do not need to fix them as much, and furnaces work longer. Studies show these bricks last up to 25% longer than regular bricks. This means fewer stops and less money spent fixing things. One steel plant in Europe had 20% more furnace use after using these bricks. A cement plant in South America saved 15% on energy because the bricks kept heat in better.

You spend less on repairs because they break less.

Factories stop less, so they work better.

Better insulation saves fuel.

Some furnaces use up to 20% less fuel.

There are 30% fewer repairs than with old bricks.

Safety is important in every factory. High alumina bricks help keep workers and machines safe. They stay strong when hot, so they do not crack or break easily. This stops hot stuff from leaking out and causing harm. The bricks also fight off chemical damage, so the furnace stays strong. When bricks last longer and need fewer fixes, workers do not have to go into dangerous places as much.

| Advantage | How It Improves Safety |

|---|---|

| High strength | Stops cracks and leaks |

| Chemical stability | Stops bad reactions |

| Fewer repairs | Keeps workers out of hot areas |

Note: Picking the right bricks helps keep people and machines safe in factories.

High alumina bricks can handle very high heat. They also do not get damaged by chemicals. These bricks are important in steel, cement, and power plants. Many factories use them because they last a long time. They work well and do not break easily.

High alumina bricks keep machines safe from very hot temperatures.

They help factories spend less money and keep workers safe.

High alumina bricks are the top pick for hard jobs where it gets really hot.

High alumina bricks have more alumina inside than regular refractory bricks. This makes them stronger and better at handling heat. Factories use them where it gets very hot.

High alumina bricks last longer in tough places.

Factories put refractory bricks in furnaces, kilns, and reactors. Steel plants, cement factories, and power stations need these bricks to keep equipment safe from heat and chemicals.

Steel industry

Cement industry

Glass industry

Yes, high alumina bricks can stand up to acids, alkalis, and slags. Their special mix helps them stay strong when they touch harsh chemicals.

| Brick Type | Chemical Resistance |

|---|---|

| High Alumina Bricks | Excellent |

| Fireclay Bricks | Good |

Refractory bricks can last from 1 year up to 10 years in a furnace. How long they last depends on how you put them in, take care of them, and the work they do.

Checking bricks often helps them last longer.

High alumina bricks help keep workers safe by stopping heat and chemicals from getting out. Their strength lowers the chance of cracks and leaks.

️ Factories are safer when they use high alumina bricks.