Views: 0 Author: Site Editor Publish Time: 2025-08-27 Origin: Site

Refractory mortar helps you stick fire brick and refractory brick together. It makes strong structures that can handle high heat. You need this special mortar because regular concrete breaks when it gets too hot. The right mortar stops cracks and keeps your fireplace or kiln safe. The market for refractory mortar is getting bigger quickly:

| Metric | Value (USD Billion) | Period | CAGR (%) |

|---|---|---|---|

| Market Size (2024) | 3.5 - 3.51 | 2024 | N/A |

| Projected Market Size (2032) | 5.17 | 2032 | 5.2 (2026-2032) |

If you use the wrong mortar, it can cause fires and expensive fixes. Always pick the right mortar to stay safe and make things last longer.

Refractory mortar is a strong glue. It can handle high heat. It holds fire bricks together. You use it in places like fireplaces, ovens, and kilns.

Using the right refractory mortar stops cracks. It keeps things safe. It helps them last longer than regular mortar.

Always follow the right steps to install it. Clean the surfaces first. Mix the mortar the right way. Let it cure slowly. This helps you avoid mistakes.

Pick refractory mortar for your project’s needs. Think about how hot it will get. Think about chemicals and work conditions. This gives you the best results.

Refractory bricks and mortar save energy. They keep heat inside. They protect buildings and equipment from heat damage.

When you build with fire brick or refractory brick, you need a special mortar. This mortar is made from heat-resistant materials. It holds the bricks together where normal mortar would not work. You use it for things like fireplaces, ovens, kilns, and furnaces. Its main job is to make a strong bond between each fire brick. This helps your structure handle very high heat. It keeps the bricks from cracking or falling apart.

Refractory mortar keeps fire brick and refractory brick tightly joined. It works even when temperatures change a lot. The mortar forms a chemical bond with each fire brick. This bond stands up to heat, thermal shock, erosion, and chemicals. Your fireplace or kiln will last longer and be safer because of this.

Tip: Always use refractory mortar with fire brick or refractory brick in places that get very hot. This makes your project safe and strong.

Refractory mortar is special because of what it is made from. The main parts are:

Aggregates: Fireclay, silica, and alumina give the mortar strength and heat resistance.

Binders: These can be natural clays or chemicals like phosphates, silicates, and aluminates. They help stick the aggregates together and make the mortar easy to use.

Additives: Retarders, accelerators, plasticizers, and anti-oxidants help control how fast the mortar sets, make it easier to work with, and make it last longer.

Different types of refractory mortar use different chemical oxides. The type you pick depends on where you will use it. For example:

| Type of Refractory Mortar | Main Chemical Components | Best Use Case |

|---|---|---|

| Acidic | Silica (SiO2), Alumina (Al2O3), Fire clay | Acidic environments |

| Silica | Over 90% silicon oxide | High thermal shock resistance |

| Aluminosilicate | Alumina and silica | General high-temperature use |

| Basic | Magnesia (MgO), Dolomite, Chrome-magnesia | Alkaline environments |

The chemical makeup lets refractory mortar handle heat up to 1650°C or more. The mortar’s refractory materials, like calcium aluminate, silica, or magnesia, react with the fire brick surface. This makes a tight, stable joint that resists heat and wear. The mortar can even expand a little at high temperatures. This keeps the joints tight and stops shrinking.

Refractory mortar also has a lot of alumina (40% to 78%) and a little iron oxide. These help the mortar fight off chemical damage and stay strong under stress.

You may wonder why you cannot use regular mortar with fire brick or refractory brick. The reason is how each mortar acts when it gets hot.

Temperature Resistance: Refractory mortar can handle heat up to 1600°C. Regular mortar, made from cement, sand, and water, cannot take that much heat. It is only good for places that do not get very hot.

Bonding Strength: Refractory mortar makes a chemical bond with fire brick and refractory brick. This bond stays strong even when the temperature goes up and down fast. Regular mortar does not do this.

Thermal Shock Resistance: Refractory mortar can expand and shrink in a controlled way. This helps stop cracks. Regular mortar cannot do this and will crack or split.

Curing Time: Refractory mortar takes a long time to cure, sometimes days or weeks. Regular mortar dries much faster but does not get as heat resistant.

Failure Modes: Regular mortar cracks when it gets too hot. The cracks spread fast, and the mortar gets weak. It can split apart, making the structure unsafe.

Here is a quick comparison:

| Feature | Refractory Mortar | Regular Mortar |

|---|---|---|

| Max Temperature | Up to 1600°C | Below 300°C |

| Main Use | Fire brick, refractory brick, high-heat areas | General construction |

| Bonding | Chemical bond with fire brick | Physical bond only |

| Thermal Shock Resistance | High | Low |

| Curing Time | Slow (days/weeks) | Fast (hours) |

| Failure Under Heat | Resists cracking and splitting | Cracks and splits easily |

Note: If you use regular mortar with fire brick or refractory brick in hot places, it can fail and be dangerous. Always use refractory mortar for safety and to make your project last.

Refractory mortar is not just a stronger glue. It is made to work with fire brick and refractory brick in tough conditions. The special mix of refractory materials, binders, and additives helps it resist heat, thermal shock, and chemicals. This is why it is the best choice for fireplaces, ovens, kilns, and furnaces.

Many homes have fireplaces and chimneys. These must handle high heat every time you use them. Fire brick lines the inside of the firebox and chimney flue. Refractory brick is used where more heat resistance is needed. You need refractory mortar to hold these bricks together. This mortar keeps joints tight and stops cracks when it gets hot fast.

Building codes say you must use refractory mortar in fireplaces and chimneys. The IRC and IBC require refractory mortar for all joints in hot areas. If you use regular mortar, you could have fire risks and insurance trouble. Some builders mix fire-clay with regular mortar, but this does not meet code. You must use medium duty refractory mortar that meets ASTM C199 and lay it by ASTM C-1283. Mortar between flue tiles must be refractory mortar to handle high heat and stop fire risks. Codes also say how thick mortar joints and airspace should be to keep fireplaces safe.

Tip: Always check local codes before building or fixing a fireplace or chimney. Using the right mortar keeps your home safe.

Fire brick and refractory brick help fireplaces last for many years. Refractory mortar makes a strong bond that resists heat, thermal shock, and chemicals. This means fewer repairs and a longer life for your fireplace. Good fireplaces with proper mortar can last over 50 years. If you use the wrong mortar, you may need repairs in 5 to 10 years.

Energy efficiency matters in fireplaces and chimneys. Fire brick acts as an insulator and keeps heat inside. Refractory mortar seals joints and stops heat from escaping through cracks. This helps your fireplace burn hotter and cleaner, saves fuel, and lowers smoke. You also protect the structure from damage caused by fast temperature changes.

Here are reasons to use fire brick and refractory mortar in fireplaces and chimneys:

Handles high heat every time you use it

Meets codes for safety and insurance

Stops cracks and joint problems

Improves energy efficiency and insulation

Makes fireplaces and chimneys last longer

You find fire brick and refractory brick in ovens and kilns for cooking, baking, and pottery. The most common example is the fire brick pizza oven. These ovens get very hot, often between 400°C and 500°C. Wood-fired pizza ovens can go above 800°C and sometimes reach 1100°C. Pottery kilns also work at very high temperatures, usually above 1000°C. You need refractory mortar to hold the bricks and keep ovens or kilns safe.

Regular mortar cannot handle these high temperatures. Calcium aluminate cement in refractory mortars can weaken between 350°C and 600°C. That is why you must pick refractory mortar made for ovens and kilns. This mortar keeps bricks together even when temperatures change quickly. It resists cracking, shrinking, and chemical attack from ash, food, or glazes.

When you build a fire brick pizza oven, you want it to last for years. Refractory mortar gives better thermal shock resistance and strength. The mortar flexes with the bricks, so joints do not fail when the oven heats up or cools down. You get a longer life and fewer repairs. Good ovens and kilns with fire brick and refractory mortar can last 7 to 15 years. Castable linings may only last 5 to 8 years. Fire brick and refractory mortar can triple the lifespan in tough places compared to alumina castables.

Kilns need even more protection. You use refractory bricks and mortar to line the inside, where it gets very hot. The mortar keeps bricks tight and resists damage from chemicals in glazes and clay. You also get better insulation, which saves energy and keeps the kiln hot longer. The right mortar helps your kiln handle fast temperature changes without cracking.

Here is a table showing temperature ranges for ovens and kilns:

| Application | Typical Temperature Range | Peak Temperature | Mortar Requirement |

|---|---|---|---|

| Fire brick pizza oven | 400°C – 500°C | Up to 1100°C | Refractory mortar required |

| Wood-fired oven | 800°C+ | Up to 1100°C | Refractory mortar required |

| Pottery kiln | 1000°C+ | Up to 1200°C | Refractory mortar required |

Note: Always use refractory mortar when building or fixing ovens and kilns. This keeps your oven safe and helps it last longer.

Energy efficiency is important in ovens and kilns. Fire brick and refractory brick act as insulators and keep heat inside the chamber. Refractory mortar seals joints and stops heat loss, saving fuel. You get better cooking results and lower energy costs. The mortar also protects the structure from damage caused by fast temperature changes and chemicals.

Here are reasons to use fire brick and refractory mortar in ovens and kilns:

Handles extreme heat and fast heating cycles

Stops cracks and joint problems

Improves energy efficiency and insulation

Makes ovens and kilns last longer

Resists chemical attack from food, ash, and glazes

You see fire brick and refractory brick in many factories. These bricks line furnaces, boilers, reactors, and other equipment that must handle high heat. Refractory mortar holds the bricks and keeps the lining strong, even when temperatures change quickly or chemicals attack the surface.

Industries that use refractory mortar include steel, cement, glass, and petrochemicals. You find refractory brick and mortar in cement kilns, power plant boilers, steel furnaces, glass furnaces, and petrochemical reactors. These places need strong linings that resist heat, wear, and chemical damage. Refractory mortar helps keep these linings safe and strong.

Here are common industrial processes that need refractory mortar:

Cement making (cement kilns)

Power and heating (boilers)

Steelmaking (big furnaces and ladles)

Glass making (glass furnaces)

Petrochemical processing (reactors)

Industrial kilns and furnaces reach up to 2,700°F (about 1,480°C) for high-duty firebrick. You need refractory mortar that can handle these tough conditions. The mortar flexes with the bricks, so joints do not crack or fail. You also get better resistance to heat cycles and chemical damage. Fire brick and refractory mortar last longer and need fewer repairs than castable linings.

Refractory mortar also helps with energy efficiency in factories. Fire brick and refractory brick act as insulators and keep heat inside the kiln or furnace. The mortar seals joints and stops heat loss, saving fuel. You get lower costs and better performance from your equipment.

Industrial repair uses refractory mortar in different ways. You may see gunning, ramming, or casting, depending on the equipment and repair needs. These methods help keep the lining strong and make the kiln or furnace last longer.

Tip: Always use refractory mortar for lining and repair in industrial kilns and furnaces. This protects your equipment and saves money on repairs.

Here is a table showing where you find fire brick and refractory mortar in industry:

| Industry | Equipment | Temperature Range | Mortar Requirement |

|---|---|---|---|

| Steel | Furnaces, ladles | Up to 1,480°C | Refractory mortar required |

| Cement | Cement kilns | Up to 1,400°C | Refractory mortar required |

| Glass | Glass furnaces | Up to 1,500°C | Refractory mortar required |

| Petrochemical | Reactors | Up to 1,200°C | Refractory mortar required |

| Power generation | Boilers | Up to 1,200°C | Refractory mortar required |

Fire brick and refractory brick help protect factory equipment from damage. The mortar keeps the lining tight and resists wear from heat, abrasion, and chemicals. You get longer equipment life and lower repair costs.

Here are reasons to use fire brick and refractory mortar in factories:

Handles extreme heat and fast heating cycles

Stops cracks and joint problems

Improves energy efficiency and insulation

Makes kilns, furnaces, and reactors last longer

Resists chemical attack and wear

Note: Using the right mortar is important for safety, energy savings, and durability in industrial kilns and furnaces.

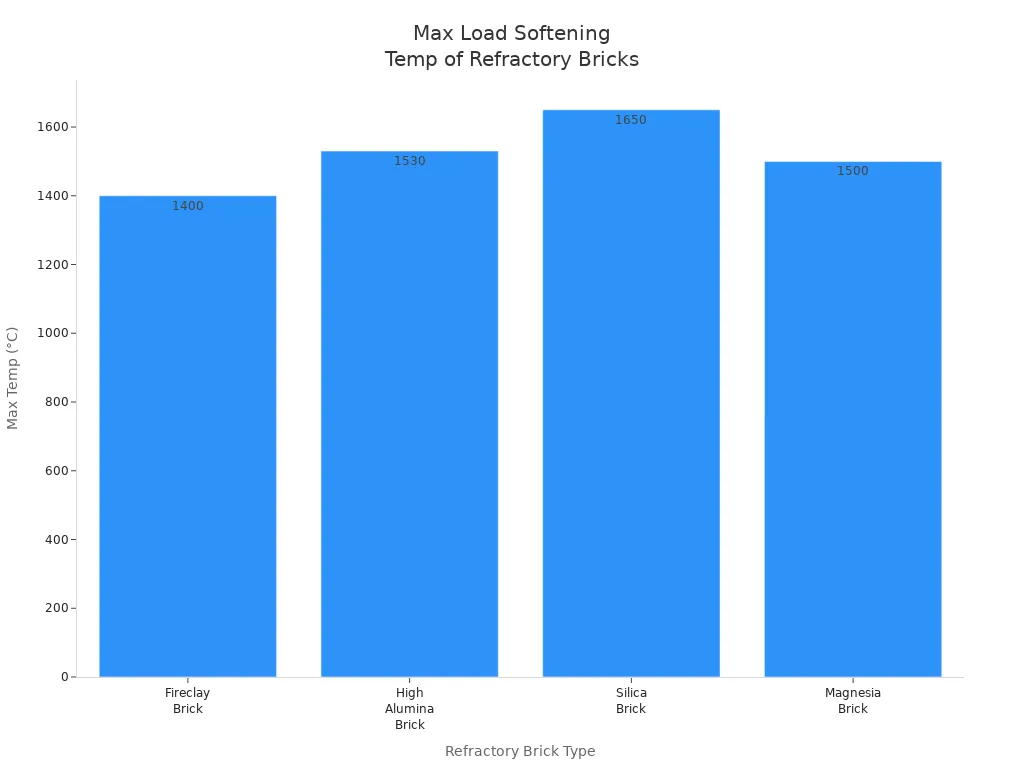

You need strong materials for places with high heat. Refractory bricks do not crack when heated and cooled fast. Tests in labs show how tough these bricks are. In these tests, bricks get very hot, like 950°C or 1100°C. Then, they cool down quickly with water or air. High-alumina and silicon carbide bricks last longer than regular bricks. They do not crack after many heating and cooling cycles. These bricks keep their strength, so your building stays safe.

| Refractory Brick Type | Load Softening Temperature Range (°C) |

|---|---|

| Fireclay Brick | 1250 - 1400 |

| High Alumina Brick | 1400 - 1530 |

| Silica Brick | 1620 - 1650 |

| Magnesia Brick | 1470 - 1500 |

Fire brick and other refractory bricks can take very high heat. They do not get soft or weak until very high temperatures. This makes them great for kilns, ovens, and furnaces.

Refractory bricks and the right mortar help keep heat inside. Insulating fire bricks do not let much heat escape. This saves energy and helps ovens and furnaces heat up faster. The bricks do not soak up much heat, so you use less fuel. Special mortar keeps joints tight and stops heat leaks. The outside of your equipment stays cooler, which is safer for workers.

Insulating bricks trap air, which does not carry heat well.

Low thermal mass means you need less energy for high heat.

Good mortar and thin joints stop heat from leaking out.

Cooler outside temperatures make work safer and more comfortable.

Using fire brick and the right mortar saves energy, lowers costs, and helps the environment.

Refractory bricks protect buildings during fires. They can take heat up to 1200°C, which is much higher than other materials. Concrete and steel get weak or break at lower heat. Fire brick keeps its shape and strength in extreme heat. The bricks also protect the inside of furnaces and kilns from damage. You will need fewer repairs.

Bricks do not crack or break under high heat.

They last longer than concrete or steel in fires.

Your equipment and building stay safer in emergencies.

Fire brick gives you peace of mind by protecting against high heat and fire damage.

You need to follow the right steps when installing refractory mortar. Start by choosing the correct type for your project. Always use clean, potable water to mix the mortar. Prepare your tools and a clean mixing container. Measure the mortar and water as the manufacturer suggests. Add water slowly and mix until the mortar is smooth and holds its shape on a trowel. If the mix is too dry, add a little water. If it is too wet, add more dry mortar. Apply the mortar within an hour for the best results.

Spread the mortar evenly with a trowel. Press the fire brick firmly into place. Make sure the joints are uniform and tight. After laying the bricks, keep the surface moist or humid for at least 24 hours. Protect the area from freezing for two days. Once cured, heat the structure slowly. Raise the temperature in small steps to avoid cracks.

You can make your project last longer by following best practices. Always clean the surface before applying mortar. Remove dust, oil, or old mortar. Use the right mortar for your fire brick or other high-heat bricks. Mix the mortar in small batches so it does not dry out. Test the consistency before use. Good ventilation helps the mortar dry. In humid places, use a dehumidifier. Monitor the moisture level during curing. After curing, heat the structure slowly to prevent thermal shock.

Tip: Use skilled workers for installation. Quality control and regular checks help you catch problems early.

Many people make mistakes when installing refractory mortar. Here is a table of common errors, their effects, and how to avoid them:

| Error Type | What Happens | How to Avoid |

|---|---|---|

| Dirty or oily surfaces | Mortar does not stick, bricks fall off | Clean and roughen surfaces |

| Wrong mortar type | Bricks erode or soften quickly | Use the right mortar for fire brick |

| Uneven joints | Cracks form, heat escapes | Keep joints even and tight |

| No expansion joints | Cracks and bulges appear | Add flexible expansion joints |

| Poor curing | Weak mortar, short lifespan | Follow curing steps and protect |

Avoid these mistakes by preparing well, using the right materials, and following each step carefully. This keeps your fire brick structure safe and strong.

There are different types of refractory mortar you can buy. Each type works best for certain jobs. Knowing the differences helps you choose the right one. Here are the main types:

Air-setting mortar cures when it touches air. It is good for quick fixes or when you need it to set fast.

Heat-setting mortar gets stronger when heated. It is used in places like kilns or furnaces that stay hot for a long time.

Hydraulic-setting mortar sets when it gets wet. It works well where temperatures change a lot or water might be around.

Phosphate-bonded mortar sticks very well and handles fast temperature changes. You see it often in kilns and furnaces.

You can pick mortar based on what it resists. Some mortars fight acids, some fight alkalis, and some are very strong. How the mortar is made also matters. Most mortars use chemical bonding, but some use hydraulic or mechanical bonding. The binder can be Portland cement, high-alumina cement, or calcium aluminate cement. Aggregates like sand, grog, clay, or silicon carbide change how the mortar works.

| Category | Subtypes / Details | Applications / Notes |

|---|---|---|

| Types by Resistance | Acid Resistant, Alkali Resistant, High Strength | Used in lime kilns, cement kilns, glass furnaces, steel mills |

| Production Process | Chemical bonding, Hydraulic bonding, Mechanical bonding | Chemical bonding is common in steel and glass industries |

| Binder Materials | Portland Cement, High-Alumina Cement, Calcium Aluminate Cement, Sodium Silicate | High-Alumina for high heat; Calcium Aluminate for glass industry |

| Aggregate Types | Sand, Grog, Clay, Silicon Carbide, Graphite | Sand for cost; Silicon Carbide for wear resistance; Graphite for high-temp |

You use refractory mortar in many places. These include fire brick pizza ovens, fireplaces, kilns, and boilers. The right mortar keeps your structure safe from heat and chemicals.

Picking the best refractory mortar takes some thinking. You want your fire brick or firebrick to last and stay safe. Here are some tips to help you choose:

Know your project needs. Check the highest temperature your project will face. Think about how big the repair is and what materials you will use.

Pick the right cement type. High-alumina cement is good for high heat. Insulating cement helps keep heat inside. Acid-resistant cement is best if you have chemicals.

Check the temperature rating. Always choose mortar with a rating that matches or beats your needs. This helps you avoid problems later.

Choose trusted brands. Buy from companies with a good name. This means you get quality and strength.

Follow standards and codes. Look for mortars tested to ASTM C199, ASTM C1655, or ASTM C198. These show the mortar can handle heat and stress.

Think about workability. Some mortars set fast, others take longer. Pick one that fits your working time. For outdoor jobs or wet places, use hydraulic-setting mortar.

Finish joints well. Make the joints smooth for a strong, neat look. This helps your fire brick structure last longer.

Tip: Always match the mortar type to your fire brick and the conditions in your kilns or ovens. This keeps your project safe and working well.

Use these tips to pick the right mortar for kilns, fireplaces, or any hot project. The right choice means better results, longer life, and fewer repairs.

Refractory Brick and mortar help keep hot projects safe. Using the right materials makes your structure strong. Good installation stops cracks and heat loss. It also protects against chemical damage. You should look for signs of wear often. Try to control how fast temperatures change. Patch small cracks to make things last longer. Groups like the Mason Contractors Association of America give good advice. Process Industry Practices is another trusted source. If you want to learn more, check ASTM F1097-17R22. You can also read books about refractory technology. Always think about safety first. Ask experts for help with hard jobs.

Refractory Brick can take very high heat and fights off chemicals. You use it in kilns, ovens, and furnaces. Regular brick cannot handle this much heat. It will crack or break if it gets too hot.

Yes, you can use Refractory Brick for pizza ovens outside. It keeps the heat inside and helps food cook evenly. It also lasts longer than regular brick. Always use refractory mortar to make the joints safe and strong.

Check how hot your project will get. Pick bricks with lots of alumina or silica for better heat resistance. Ask suppliers like Yufeng Refractory for help. They can suggest the best brick for your oven, kiln, or furnace.

You must use refractory mortar when you put in Refractory Brick. Regular mortar will not work in high heat. Refractory mortar makes strong joints that resist heat and keep your project safe.

Refractory Brick can last many years in hot places if you install it right and use the correct mortar. Check for cracks often and fix them fast. This helps your oven, kiln, or furnace work well for a long time.