Views: 1 Author: Site Editor Publish Time: 2025-08-18 Origin: Site

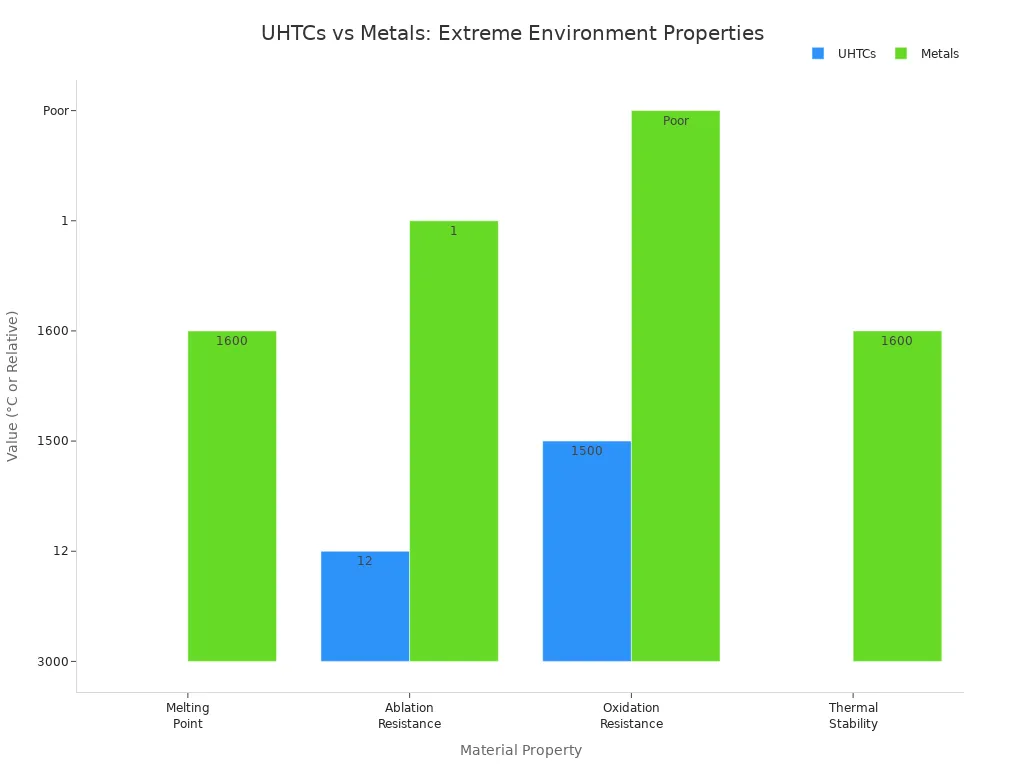

Refractory ceramic is special because it can handle very high heat, strong chemicals, and heavy force. These ceramics, especially ultra-high temperature types, do not melt easily and stay strong when hot. Factories use refractory materials in places where metals cannot work. The table below shows how refractory ceramics and metals are different:

| Property | UHTCs (Zr, Hf, Ta carbides/borides/nitrides) | Metals (typical aerospace alloys) |

|---|---|---|

| Melting Point (°C) | > 3000 | < 1600 |

| Thermal Conductivity (W/m·K) | High (varies, but generally > metals at high T) | Moderate to low |

| Thermal Expansion (10^-6 K^-1) | Low to moderate (10.65–10.84 × 10^-6) | Higher, leading to thermal stress |

| Fracture Toughness | Lower but improved with composites | Higher but degrades at high T |

Refractory ceramics keep working when metals break down or melt. Their high melting point and ability to resist chemicals help them work safely in tough places.

Refractory ceramics can handle very high heat. They also resist strong chemicals and force. This makes them good for tough places where metals do not work.

These materials have many types and shapes. People pick them based on how much heat they can take. Their chemical makeup and strength matter for each job.

Ultra-high temperature ceramics (UHTCs) can handle heat over 2000°C. They are important in aerospace, energy, and steel work.

Important features are thermal stability and mechanical strength. Chemical resistance and thermal shock resistance help them last a long time.

New ideas in materials and making them make these ceramics stronger. They also help the environment and let us use them in new technology.

Refractory ceramic is a group of materials made to work in very hot and harsh places. Scientists say refractory ceramics can handle heat above 1000°C and still keep their shape and chemical makeup. These materials do not melt, break down, or wear out easily. This makes them important for factories that use furnaces, kilns, and reactors.

Ultra-high temperature ceramics (UHTCs) are a special kind of refractory ceramic. UHTCs can take heat above 2000°C and sometimes even more than 3000°C. They are made from things like borides, carbides, and nitrides of metals such as zirconium, hafnium, and tantalum. These ceramics move heat well and do not crack when the temperature changes quickly.

Refractory ceramics are not the same as other ceramics. Regular ceramics, like those used for pottery or tiles, are made from natural things like clay and feldspar. These work fine for daily use but cannot last in very hot places. Advanced ceramics, including refractory types, are made from pure powders and built to be strong and tough at high heat. Refractory ceramic materials are made to stay stable in heat and chemicals, so they are the best choice for hard jobs.

Note: Refractory ceramics do more than just resist heat. They also do not let heat pass through easily, can hold a lot of heat, and do not get damaged by chemicals. These features help protect machines and keep people safe in places like steel plants, glass factories, and aerospace.

Refractory ceramics come in many types for different jobs. Experts sort refractories by shape, what they are made of, how heavy they are, and their chemical features. This sorting helps people pick the right one for each job.

Shaped Refractories: These are things like bricks, special shapes, crucibles, and nozzles. Factories press these into set shapes to fit kilns and furnaces.

Unshaped Refractories: These are also called monolithic refractories. They include mortars, castables, plastics, and ramming mixes. Workers put them in place at the job site, so they fit any shape needed.

Silica-Based Refractories: Silica bricks and fused silica have at least 93% silicon dioxide (SiO₂). They do not get damaged by acidic slags and are good for glass furnaces.

Alumino-Silicate Refractories: These are fireclay bricks, high alumina bricks, and mullite products. Mullite is popular because it works well and does not cost too much, but it can break down with some molten metals.

Magnesia-Based Refractories: Magnesia bricks and magnesia-alumina bricks use magnesium oxide (MgO). They can take high heat and do not break down in tough places. These are great for steelmaking.

Carbon-Based Refractories: Graphite and coke-based products do not crack from quick heat changes and do not get damaged by chemicals.

Advanced Refractory Materials: Zirconia, carbides, and nitrides work very well at very high heat. These are often used in aerospace and energy.

Dense Refractories: Firebricks and other dense materials are strong and do not wear out fast. They line furnaces and reactors that get very hot and face chemicals.

Insulating Refractories: These are light and keep heat in. They also do not get damaged by chemicals. Factories use them to stop heat loss and protect against chemicals.

Acidic Refractories: Made mostly of SiO₂, these do not break down from acidic slags.

Basic Refractories: Made from MgO and CaO, these do not break down from basic slags.

Neutral Refractories: These do not break down from either acidic or basic slags, so they work in many places.

| Main Category | Subcategories / Types | Distinguishing Features |

|---|---|---|

| Shaped Refractories | Standard bricks, Special shapes | Set shapes, pressed by machine; used in kilns and furnaces with fixed designs |

| Unshaped Refractories | Mortars, Castables, Plastics, Ramming mixes, Gunning mixes | Put in place on-site; no joints; monolithic |

| Dense Refractories | Firebricks, high-density materials | Strong, do not wear out fast, good for tough places |

| Insulating Refractories | Lightweight refractories | Light, keep heat in, resist chemicals |

| Chemical Composition | Silica-based, Alumino-silicate, Magnesia-based, Carbon-based, Advanced (Zirconia, Carbides/Nitrides) | Each type resists certain things: acidic/basic slags, heat shock, high heat |

| Chemical Properties | Acidic, Neutral, Alkaline | Shows what slags they resist; acidic for acidic slags, basic for basic slags, neutral for both |

Alumina (Al₂O₃), magnesia (MgO), and aluminosilicates are the main parts of many refractory ceramics. Aluminosilicate refractories, like mullite, are popular because they work well and do not cost too much. Magnesium-aluminate spinel (MgAl₂O₄) can take high heat, does not expand much, and does not crack from quick heat changes. Magnesia-based refractories are very good at resisting basic slags and tough places, so they are needed for furnace linings.

Tip: The best refractory material depends on where it will be used. For example, if a factory works with molten aluminum, it needs materials that do not break down from chemicals or crack from quick heat changes.

Refractory ceramic materials are very important in today’s factories. Their special features and many types help engineers solve hard problems. Whether used as bricks or as a smooth lining, refractories keep high-temperature jobs safe, efficient, and long-lasting.

Refractory materials are special because they work well in tough places. They can handle high heat, strong forces, and harsh chemicals. These features make them important for steel, glass, and aerospace industries.

Thermal stability means a refractory keeps its shape and job when it gets very hot. Most refractory materials have a high melting point. They do not melt or get soft, even above 2000°C. This is important for furnace linings and rocket nozzles. These parts need to stay strong in heat.

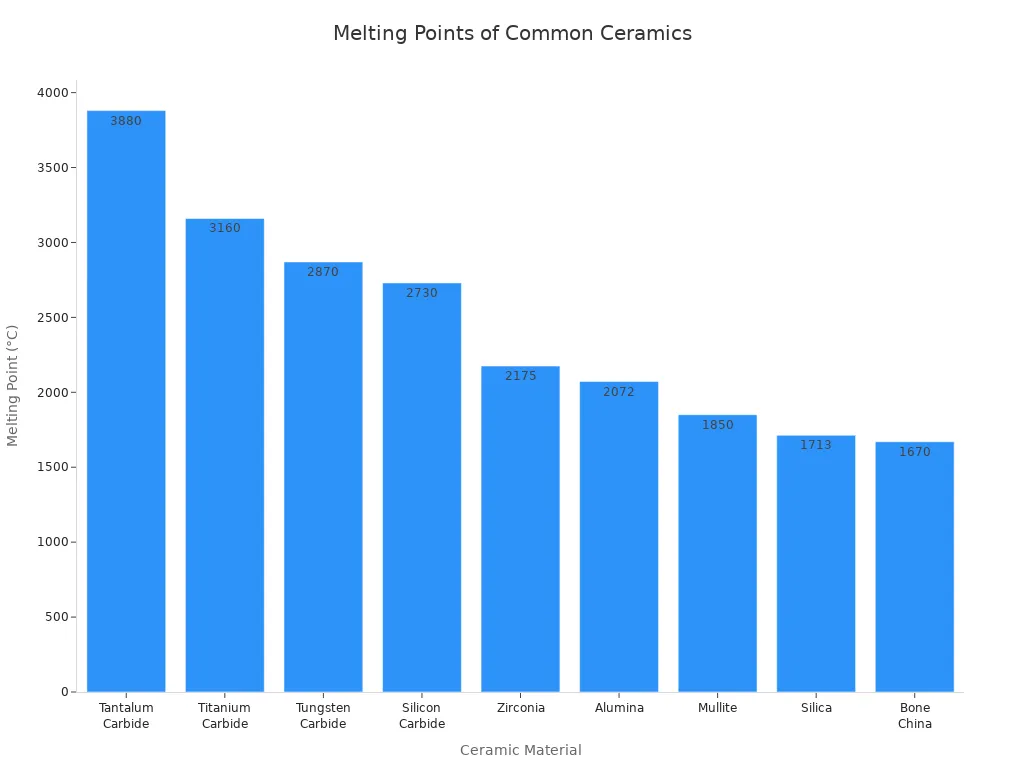

The table below shows how different refractory ceramics melt compared to other things:

| Ceramic Material | Typical Melting Point (°C) | Notes on Material and Comparison to Other Materials |

|---|---|---|

| Tantalum Carbide | ≈ 3880 | Extremely high melting point; used in aerospace; far exceeds most metals' melting points |

| Titanium Carbide | ≈ 3160 | Very high melting point; used for cutting tools; surpasses many metals |

| Tungsten Carbide | ≈ 2870 | High melting point; known for wear resistance; higher than many metals |

| Silicon Carbide | ≈ 2730 | High melting point; excellent wear and chemical resistance; used in thermal processing |

| Zirconia | ≈ 2700 | High melting point; used in aerospace and energy systems |

| Alumina | ≈ 2045 - 2072 | High melting point ceramic; used in industrial applications |

| Mullite | ≈ 1840 - 1850 | Traditional ceramic; lower melting point than carbides |

| Porcelain | ≈ 1700 - 1927 | Traditional ceramic; lower melting point; used in dinnerware and ornaments |

| Silica | ≈ 1710 - 1713 | Good thermal shock resistance; used in aerospace |

| Bone China | ≈ 1670 | Type of porcelain; lower melting point; used for decorative items |

| Fire Bricks | ≈ 1540 - 2200 | Refractory material; suitable for kiln and furnace linings; melting point varies |

| Glass Ceramics | ≈ 850 - 1723 | Lower melting points; used for cookware and durable everyday items |

These numbers show that some refractory ceramics, like tantalum carbide and silicon carbide, melt at much higher temperatures than most metals. This is why they are picked for jobs with lots of heat, where other materials would not last.

People test thermal stability by heating the material with lasers and watching it with special cameras. These tests help engineers see how the material acts when it heats up and cools down fast. This makes sure the refractory can do its job in today’s factories.

Note: The high melting point and thermal stability of refractories keep machines safe and working longer, even in very hard conditions.

Mechanical strength is another important feature of refractory materials. They must not break, crack, or bend under heavy weight or shocks. Ultra-high temperature ceramics, like silicon nitride and alumina, keep their strength even when hot. This makes them good for kilns, reactors, and other places with lots of stress.

Technical ceramics are very strong when squeezed, more than when pulled.

Silicon nitride is tough and strong at high heat, so it works in hard jobs.

Alumina is hard and resists wearing out. Pure alumina is even stronger.

Silicon carbide is very hard and stiff but not heavy. This helps when both light weight and strength are needed.

Zirconia is good at stopping cracks, taking hits, and lasting a long time under stress.

Refractory materials keep their shape and strength after getting hot. They also go back to normal after cooling, which is important when they heat up and cool down many times.

How strong a refractory is depends on what it is made of and how it is put in place. Good installation and care help refractories handle shaking, hits, and changes in size from heat. For example, adding zirconia to alumina–mullite ceramics helps stop cracks from growing when the temperature changes fast. This keeps the refractory strong after quick heating and cooling.

| Property/Factor | Effect of Porosity/Density | Impact on Refractory Performance in High-Temperature Applications |

|---|---|---|

| Porosity | Volume percentage of voids (open and closed pores) | Influences thermal conductivity, mechanical strength, corrosion resistance, thermal shock resistance |

| Thermal Conductivity | Lower porosity (higher density) increases conductivity | Dense refractories conduct heat better, suitable for load-bearing and abrasive environments |

| Higher porosity reduces conductivity | Beneficial for insulating refractories to retain heat | |

| Mechanical Strength | Inversely related to porosity | Higher density improves strength; high porosity decreases strength and durability |

| Corrosion and Erosion | Higher porosity increases exposure to corrosive agents | Low porosity enhances resistance to slag and molten metal penetration |

| Thermal Shock Resistance | Controlled porosity can relieve thermal stress | Improves resistance to cracking; excessive porosity causes cracking and spalling |

| Density | Inversely related to porosity | Higher density improves strength and slag resistance but may reduce insulation |

| Manufacturing Controls | Particle size, forming method, firing temperature, additives | Critical to tailor porosity and density for specific application needs |

| Application Examples | Low porosity for glass furnace crowns; high porosity for insulation | Balances between strength, insulation, and thermal shock resistance depending on use |

Tip: Dense refractory bricks are stronger and resist damage from chemicals. But if they are too dense, they do not insulate as well. Engineers must find the right balance for each job.

Refractory materials must not get ruined by acids, bases, slags, or other harsh chemicals. Chemical resistance means the refractory does not fall apart or lose strength when it touches strong chemicals at high heat.

Alumina ceramics do not lose much mass in acids.

More alumina in alumina-silica ceramics helps them resist bases.

Additives like zirconia, zircon, titanium oxide, and chromium oxide make refractories better at fighting off corrosion.

Corundum and mullite in refractories help them resist chemicals.

Adding zircon helps stop molten slags from getting in, making the refractory stronger and more stable.

High density and a good structure keep out slag and make refractories last longer.

People test chemical resistance with special tests, like the crucible cup test and ASTM C987. They also use tools like scanning electron microscopes and X-ray diffraction to see what happens to the material after testing.

Alert: What the refractory is made of, what chemicals it faces, and how long it is exposed all change how well it resists chemicals. Engineers must pick the right refractory for each place to make it last longer.

Thermal shock resistance (TSR) is how well a refractory can handle quick temperature changes without cracking. This is important for things like steel ladles and rocket nozzles, which heat up and cool down fast.

TSR depends on both how strong and how heat-resistant the material is, plus outside factors and the heat around it. Engineers measure TSR by seeing how much temperature change a material can take before it cracks. For example, ZrB2–SiC composites with graphite can handle temperature jumps up to 1000°C. Some new UHTC composites can take even bigger jumps, over 1480°C.

| Aspect | Details |

|---|---|

| Typical TSR values | Temperature differences up to 1000 °C for ZrB2–SiC composites with graphite additions |

| Quantification parameters | Critical rupture temperature difference (ΔT_C), thermal stress fracture resistance, thermal stress damage resistance |

| Influencing factors | Mechanical and thermal properties, external constraints, thermal environment, component geometry |

| Modeling approaches | Stress reduction factors, finite element method (FEM) considering thermo-physical properties |

| TSR expression | Maximum temperature difference material can withstand without cracking or failure |

| Additional considerations | Initial temperature, heating/cooling rates, external constraints, damage tolerance, fracture toughness |

| Application context | Thermal protection systems in aerospace, hypersonic leading edges, re-entry structures |

Tests show that materials with higher fracture toughness and damage tolerance stay strong after many quick temperature changes. Adding zirconia to alumina–mullite refractories helps stop cracks and keeps the material strong after many cycles.

Note: Good installation and care, plus a well-designed structure, help refractories resist thermal shock and last longer.

Refractory ceramics are also great electrical insulators. Their dielectric properties depend on frequency, structure, and what phases are inside. For example, mullite-based composites have a high dielectric constant at low frequencies. This helps them insulate electricity in furnaces and electronics, even when hot.

Density and porosity are very important for how well refractory materials work. Higher density means fewer holes, which makes the material stronger and better at stopping slag. But some holes are needed to help with heat stress and insulation. Engineers control porosity by picking the right raw materials, shaping methods, and firing steps to get the best mix for each job.

Tip: The right mix of density and porosity gives refractories both strength and insulation, so they work well in modern factories.

Factories use refractory ceramic materials to keep equipment safe. These materials protect machines from very hot temperatures and strong chemicals. Ceramic refractory bricks cover furnaces, kilns, and reactors. This keeps the building strong and steady. Workers pick oxide refractory shapes like alumina, mullite, and zirconia because they stay strong when hot. Special bricks such as Alundum, Alfrax, and Mullfrax work well in tough places. Kiln furniture, like saggers and rollers, holds things during firing and does not break in high heat.

| Industrial Sector | Application in Furnaces, Kilns, and Reactors | Key Properties Utilized |

|---|---|---|

| Metallurgy (Steelmaking) | Lining of blast furnaces and forges | Thermal insulation, mechanical strength, durability |

| Cement Industry | Rotary kilns and high-heat equipment | Structural stability, energy efficiency |

| Glass Manufacturing | Glass-melting furnaces | Corrosion resistance, purity, high temperature |

| Kiln Furniture | Saggers and rollers for firing | Thermal shock resistance, mechanical strength |

Ceramic refractory bricks and refractory ceramics keep equipment safe by fighting off corrosion and stopping creep. They also do not change shape from heat. Adding nanoparticles makes these materials stronger and last longer. This helps factories have safe and tough linings that work for a long time.

Refractory ceramic materials are very important in power plants and chemical factories. They line furnaces, pipes, and reactors that get hotter than 1000°C. In chemical plants, refractory ceramics do not wear out from erosion or strong chemicals in gasifiers and reformers. Ceramic catalysts and carriers help make fuels and chemicals. They also help lower pollution.

Refractory ceramics keep heat inside, so equipment stays cool and safe.

Ceramic fiber coatings can take up to 1400°C. They do not let heat pass through easily and do not wear out from rubbing.

High-purity ceramic refractory bricks help machines last longer and need less fixing.

Refractory ceramic materials help save energy and keep workers safe. Because they last a long time, factories stop less often and lose less energy. This helps make work safer and better for the environment.

Ultra-high temperature ceramics (UHTCs) protect parts in planes and rockets from very hot heat and strong force. These refractory ceramics can take heat over 2000°C. This makes them good for thermal protection systems in spacecraft and fast planes. UHTCs like ZrB2-SiC composites stay strong and do not rust when coming back through the air.

UHTCs help make light turbine blades and engine parts. This means less cooling is needed and engines work better.

Advanced ceramic matrix composites stay strong after quick changes in heat. This helps parts last longer during flight.

Ceramic refractory bricks and coatings protect engines and exhausts from rust and wearing out.

Aerospace engineers use refractory ceramic materials to build safer and better vehicles. These ceramics help machines work well in the hardest places. This lets people make new things for space and flying.

Scientists are making new refractory ceramic materials for tough places. They want to make ultra-high temperature ceramics stronger and last longer. They also want them to resist rust from oxygen. One new idea is Ultra-High Temperature Ceramic Matrix Composites, or UHTCMCs. These mix carbon fibers with zirconium diboride. The process uses reactive melt infiltration. This helps control how the fibers line up and what the matrix is made of. The result is ceramic refractory bricks that can take heavy loads.

Researchers are also trying new ways to make these ceramics. They use additive manufacturing and spark plasma sintering. These methods help make special shapes and tiny structures inside the ceramics. Computers and artificial intelligence help guess how the ceramics will work before making them. New mixes use transition metal borides, carbides, rare-earth oxides, and silicates. These help the ceramics stay strong in heat and fight off rust. This makes ceramic refractory bricks better for hypersonic vehicles and energy systems.

| Modification | Mechanism | Performance Improvement | Quantitative Results |

|---|---|---|---|

| Nano-laminated BN modified graphite | Dense ceramic layers formation | Enhanced oxidation and thermal shock resistance | Oxidation index reduced by 34%, residual strength after shock increased by 224% |

| MgO content increase | Spinel formation | Improved densification and slag resistance | Hardness: 14.22 GPa, Bending strength: 80 MPa |

New ceramic coatings and smaller particles help refractory ceramic materials last longer. This means less fixing and lower energy bills.

Making refractory ceramics uses a lot of energy and raw materials. This can hurt the environment. Now, companies use better mining methods and try to make less pollution. Making ceramic refractory bricks often means heating carbonate minerals. This lets out CO2 gas. To help, companies recycle old refractory ceramics. They also reuse waste like kaolin, sewage sludge, and blast furnace slag. These steps cut down on trash and save money on new materials.

Furnaces now use refractory ceramic materials that do not hold much heat and give off more energy. Silicon carbide is one example. This can lower CO2 by up to 10%. Rules about air pollution and carbon help cut down on dust, NOx, and SO2. Life cycle checks show that recycling and using ceramic refractory bricks longer helps the planet even more.

♻️ Recycling and reusing refractory ceramics helps the earth and saves money for companies.

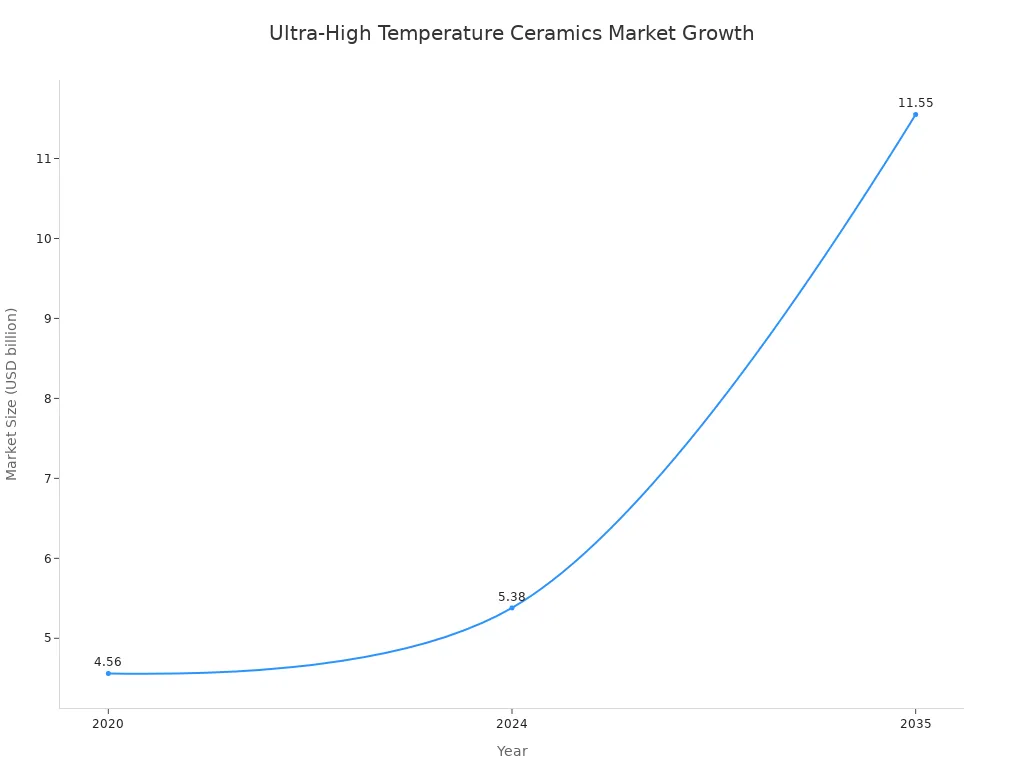

Ultra-high temperature ceramics are changing as more people need them for planes, defense, and energy. Scientists want to make refractory ceramic materials better at fighting rust, easier to shape, and able to handle quick heat changes. Nanotechnology and additive manufacturing help make special ceramic refractory bricks for fast planes and reusable space vehicles.

Asia-Pacific is growing fast because it spends a lot on new materials. New rules for the environment push companies to find better ways to make and reuse ceramics. Machine learning helps make refractory ceramic materials last longer and work better. Scientists are also looking at using leftover silica from rice husk ash and steel fibers to make ceramics stronger and less likely to break.

UHTCs are now used in electronics and sensors for hot places.

Big companies spend money on research to make eco-friendly ceramic refractory bricks.

The market is expected to grow 8-10% each year, with North America and Asia-Pacific leading.

The future of refractory ceramics is in green production, new composites, and smart ways to make them. This will help keep people and machines safe in tough places.

Refractory ceramics work very well in tough places. They keep machines safe and help people stay safe too. These materials also help factories grow in a good way.

Refractory ceramic materials and ceramic refractory bricks can take high heat. They do not break from heavy weight or strong chemicals. This helps steel, energy, and glass factories work safely.

New ideas in refractory ceramics help factories use less energy and make less pollution.

The world is using more refractory ceramics every year. People find new ways to use them in planes, power plants, and electronics. In the future, new inventions will make these materials even safer and better for the planet.

Refractory ceramics can handle very high heat and tough places. Industries use these materials because they do not melt or wear out easily. Ceramic refractory bricks protect machines in steel, glass, and energy plants. This makes work safer and helps things run better.

Ceramic refractory bricks can take much more heat than normal bricks. They do not get damaged by chemicals or quick temperature changes. Regular bricks break or melt when it gets too hot. But refractory ceramic bricks stay strong in furnaces, kilns, and reactors.

Factories use refractory ceramic materials in furnaces, ovens, and reactors. Power plants, steel mills, and glass factories need these ceramics to work safely. Some home ovens and fireplaces also use ceramic refractory bricks to stop heat from causing damage.

Refractory ceramics melt at higher temperatures than most metals. They do not rust or break from quick heat changes. Metals can bend or melt in very hot places. But refractory ceramic materials stay strong and do not change shape, so they are best for hard jobs.

Engineers pick refractory ceramic materials by looking at heat, chemicals, and force. They think about the type of ceramic refractory bricks, how dense they are, and if they resist rust. Companies like Yufeng Refractory help people choose the best ceramics for each job.