Views: 7 Author: Site Editor Publish Time: 2020-05-24 Origin: Site

Thermal conductivity means how fast heat moves through something. In fireclay, this decides how well fire clay bricks keep out heat. Fireclay brick and fire clay bricks do not let heat pass easily. Their thermal conductivity is about 0.1272 to 0.1441 W/mK. Fire clay is important because it holds air in tiny holes. This slows down how fast heat moves. Fire clay bricks help stop energy from being wasted. They also make furnaces and homes safer. Fire brick and fire bricks give strong insulation. This shows why fire clay is important for factories and homes. When picking a fireclay, people should think about how it helps fire brick work well.

Picking the best fireclay brick or fire clay bricks can keep machines safe and save energy. The way fireclay and fire brick are made helps keep heat in and keeps people safe.

Fireclay bricks do not let heat pass through easily, so they keep furnaces warm and help save energy.

The correct mix of minerals in fireclay makes the bricks strong, able to handle heat, and good at stopping heat from escaping.

Fireclay bricks protect machines because they can take high heat, fight off chemicals, and do not break when temperatures change fast.

Factories use fireclay bricks to use less fuel, spend less money, and keep workers safe from heat.

Picking fireclay bricks with the right amount of holes and clean materials helps make insulation better and helps furnaces last longer.

Thermal conductivity tells us how fast heat moves in a material. If a material has high thermal conductivity, heat moves through it fast. If a material has low thermal conductivity, heat moves slowly. This is important for things that need to keep heat in or out, like ovens or furnaces. People use "thermal conductivity" to see how different materials handle heat.

For refractory materials, thermal conductivity helps pick the best one for insulation. The American Society for Testing and Materials, or ASTM, makes the rules for measuring this. ASTM C201-24 says the units are inch-pound units, written as Btu·in./h·ft²·°F. Scientists and engineers sometimes use SI units, like watts per meter per kelvin (W/m·K). But in the United States, inch-pound units are the main ones for tests.

Thermal conductivity numbers can change with the type and structure of a material. Most insulating refractory materials have low numbers. This means they do not let heat move through them easily. For example, fireclay bricks have values from 0.1272 to 0.1441 W/m·K. These numbers show fireclay bricks are good at keeping heat inside ovens or furnaces. They also help keep the outside from getting too hot.

Other refractory materials can have higher or lower numbers. Materials with more air pockets or less density usually have lower thermal conductivity. This makes them better for insulation. When people pick materials for hot jobs, they look at these numbers. They want to save energy and keep things safe.

Note: Always check the thermal conductivity numbers before choosing insulation. Picking the right one can help save energy and make things safer.

Thermal insulation helps save energy in places that use fireclay brick. When a furnace uses fireclay refractory brick, less heat gets out. This means the machine does not need as much energy to stay hot. Fireclay brick with low thermal conductivity keeps heat inside. This stops the furnace from wasting energy.

Fireclay brick with low thermal conductivity keeps heat from escaping furnaces.

Less heat loss means lower energy costs and better temperature control.

Even thin fireclay refractory brick can give strong insulation, so machines are lighter and work better.

Good insulation keeps the outside of the furnace cooler, making work safer.

Using fireclay brick for insulation helps companies spend less money and use less fuel. It also helps lower CO2 emissions, which is good for the planet. Engineers pick fireclay brick that keeps heat in and helps machines work well.

Fireclay brick keeps heat where it is needed, so machines last longer and use less energy.

Fireclay brick can handle very high heat without breaking. This makes it great for kilns, ovens, and furnaces. Fireclay refractory brick keeps its shape and stays strong even when it gets very hot.

Materials with low thermal conductivity, like fireclay brick for sale, keep the inside of the furnace hot and the outside cool. This keeps workers and equipment safe from burns or harm. Fireclay brick also spreads heat evenly, which helps make better products.

Fireclay brick does not get damaged by high heat.

It gives strong insulation, so heat stays inside the furnace.

The brick helps control heat and makes sure products cook or melt the right way.

Fireclay refractory brick gives strong protection and keeps machines safe at high heat. Companies trust fireclay brick for sale because it lasts long and saves energy.

Fireclay is the main part of many fire clay bricks and fireclay refractory bricks. What is inside fire clay decides how well fireclay brick works in hot places. Fireclay mostly has two main minerals: silica (SiO₂) and alumina (Al₂O₃). Silica is usually between 60% and 96%. Alumina is between 2% and 36%. These minerals help fireclay resist heat and stay strong.

Other elements are in smaller amounts. These are iron, calcium, magnesium, titanium, sodium, potassium, lithium, and free silica. Lime, magnesia, iron oxide, and alkalis are called fluxing agents. These are kept low, about 2% to 6%, to keep fireclay refractory bricks strong at high heat. High alumina and low iron oxide, lime, magnesia, and alkalis are best for heat resistance and plasticity.

Kaolinite is the main clay mineral in fireclay. When heated, kaolinite loses water and turns into metakaolin and mullite. These new forms make fire clay bricks better for hot jobs. Different clays like flint, kaolin, and plastic clays are mixed to get the right properties. Flint clay is hard and used for high-duty fireclay brick. Kaolins are a bit soft and help with shaping and sticking. Plastic clays make it easier to shape the bricks.

What is inside fire clay changes how fireclay refractory bricks work. Good fire bricks need the right mix of minerals for strength and heat resistance.

Main components of fireclay:

Silica (SiO₂): 60–96%

Alumina (Al₂O₃): 2–36%

Kaolinite: Main clay mineral, changes to mullite when hot

Small amounts of iron, calcium, magnesium, titanium, sodium, potassium, lithium, and free silica

Fluxing agents (lime, magnesia, iron oxide, alkalis): 2–6%, kept low for high heat strength

How fire clay acts, like how easy it is to shape and how well it handles heat, depends on what is inside. The right mix helps fireclay refractory bricks work well in furnaces and other hot places.

Fireclay brick is special because it has a good mix of physical and chemical properties. These make fire clay bricks great for insulation and lining in furnaces, kilns, and other hot places. The properties of fireclay refractory bricks come from what minerals they have and how they are made.

| Property | Description |

|---|---|

| Chemical Composition | Hydrated aluminum silicate; alumina content changes by type (Super-duty: 40-45% Al₂O₃) |

| Classification | Super-duty, High-duty, Medium-duty, Low-duty, Semi-silica bricks |

| Water Absorption | Very low or none, shows low porosity and chemical safety |

| Vitrification | Partly melts during firing, making it stronger and safer from chemicals |

| Bulk Density | About 2.52 Mg/m³ |

| Compressive Strength | Around 1.77 GPa |

| Thermal Conductivity | Moderate to low, usually 4–6 W/m·K for some fireclay bricks |

| Thermal Shock Resistance | Good, can handle heating and cooling many times |

| Refractoriness | Medium to high, can take up to about 1000°C |

| Porosity and Density | Lower density and more holes than other refractories, helps with insulation |

| Chemical Resistance | Good, does not get damaged easily by acids or alkalis |

| Temperature Limit | Usually up to 1000°C, some types work around 350°C in air |

Fireclay refractory bricks are very good at handling heat. They can be heated and cooled many times without breaking. This means fire clay bricks last longer in furnaces and kilns. Because they have low porosity and are partly melted, fireclay brick does not get damaged by acids or alkalis.

Fireclay brick can hold heavy loads, with compressive strength about 1.77 GPa. The moderate to low thermal conductivity helps fireclay refractory bricks keep heat inside furnaces and save energy.

Fireclay refractory bricks are strong, resist heat, and do not get damaged by chemicals. These things make fire clay good for hot and tough places.

Fireclay brick also keeps its shape well. At 1400°C, it only changes size a little, between -0.5% and +0.5%. This means fire clay bricks do not warp even in very hot places. Fireclay refractory bricks also hold heat well, which helps furnaces use less energy.

Key characteristics of fireclay refractory bricks:

Good at handling quick changes in heat (10–15 cycles)

Can resist acids and alkalis

High alumina (30–50%) for heat stability

Strong and does not soak up much water

Good insulation because of low thermal conductivity and many small holes

These things make fireclay brick a trusted material for many industries. The properties of fire clay help fireclay refractory bricks work well in hard jobs.

Fireclay brick and fire clay bricks are important in many industries. Their low thermal conductivity, heat resistance, and strength make them a top choice for lining and insulating hot equipment. Fireclay refractory bricks are used as both main linings and backup linings in furnaces, kilns, and other hot machines.

Common industrial uses of fireclay refractory bricks:

Steel industry: Used in blast furnaces, hot blast stoves, and ladles

Aluminum industry: Lining for melting and holding furnaces

Foundry operations: Coreless induction furnaces and cupolas

Cement production: Kiln linings and preheater cyclones

Incineration plants: Lining for waste incinerators

Power generation: Boiler linings and ash hoppers

Paper industry: Recovery boilers and lime kilns

Fireclay brick gives strong insulation and protects machines from fast temperature changes. Fireclay refractory bricks do not wear out quickly and can handle harsh chemicals, which is important in tough places. Good fire bricks also help keep temperatures steady, which makes products better and saves energy.

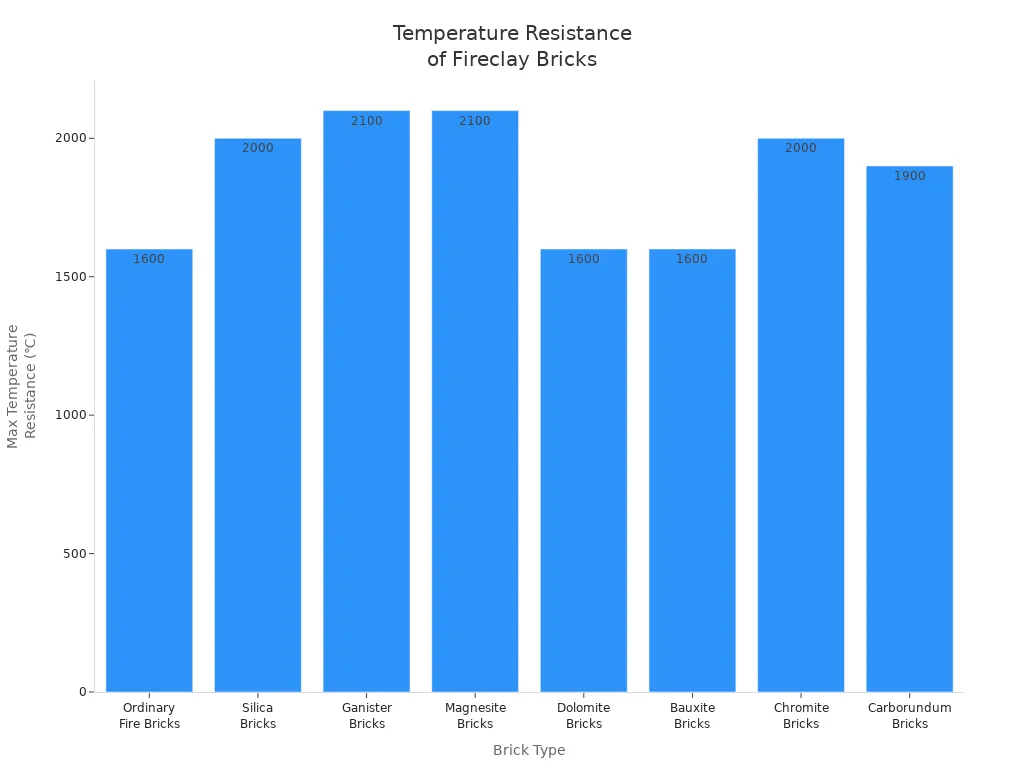

How well fireclay brick works for different jobs depends on what is inside. Ordinary fire bricks have 50–75% silica and 20–40% alumina, so they are good for acid linings in furnaces. Silica bricks, with about 95% silica, are used in glass furnaces and steel furnace walls. Magnesite and dolomite bricks, with more basic content, are used in basic furnace linings. Each fireclay refractory brick type fits certain jobs based on what it is made of and how much heat it can take.

Fireclay refractory bricks are tough and can be used in many ways. Industries use fire clay bricks to protect machines, save energy, and keep things safe in hot places.

Fireclay brick, fire clay bricks, and fire bricks are still very important for today’s industries. Their mix of heat resistance, chemical strength, and insulation makes them a key part of many brick setups. Good fire bricks and refractory fire bricks help industries meet safety and energy rules.

Porosity and density are very important for fireclay brick. Porosity means how many air spaces are inside the brick. These spaces can be open or closed. Closed pores trap air and help stop heat from moving. This makes the brick a better insulator. Spherical pores stop heat better than long, tube-shaped pores. The size and shape of these pores change how heat moves in the brick.

A brick with low porosity has fewer air spaces. This makes the brick dense and strong. Dense bricks can hold heavy things and do not wear out fast. Low porosity also keeps water out, so the brick stays dry and strong. Powders and fibers can be added to change porosity. This changes how well the brick insulates and how strong it is.

Closed pores help stop heat from moving.

Round pores insulate better than tube-shaped pores.

Dense bricks can hold more weight.

Low porosity keeps water and chemicals out.

Fireclay brick with low porosity and high density insulates better and lasts longer in tough places.

Temperature changes can affect fireclay brick in many ways. At high heat, the brick must keep its shape and strength. High temperature stability is needed for furnaces and kilns. When the heat goes above 1200°C, bricks with more pores are more affected by gas pressure. This can make heat move faster and lower insulation.

Fireclay refractory brick can handle quick changes in heat. It does not crack when heated or cooled fast. The brick’s structure helps it stay strong in very hot places. Fireclay brick for sale often shows its heat limits and how stable it is. This helps people pick the right brick.

| Temperature Range | Effect on Fireclay Brick |

|---|---|

| Below 1000°C | Keeps shape and insulates well |

| 1000–1200°C | Small changes in heat movement |

| Above 1200°C | More pores make it less stable |

Fireclay brick that stays strong at high heat protects machines and saves energy.

Fireclay and high-alumina bricks are both used in hot places. Fireclay has silica and alumina, but less alumina than high-alumina bricks. High-alumina bricks have more alumina, so they are stronger and can take more heat. Fireclay brick is good for most furnaces because it works well and does not cost much. High-alumina bricks can handle hotter temperatures and tough chemicals, but they cost more.

Thermal conductivity is different for each material. Fireclay brick has lower thermal conductivity than high-alumina bricks. This means fireclay keeps heat inside furnaces better. High-alumina bricks are strong, but they let more heat out, especially when it gets very hot.

Insulating castables are another kind of refractory material. They come as powders and are mixed with water before use. Workers pour or shape them to fit where needed. Fireclay brick is already shaped and fired, so it is ready to use. Both give good insulation, but fireclay brick is usually stronger and lasts longer.

Fireclay brick has a set shape and size, so it is easy to install and replace. Insulating castables can fill odd spaces and fix damaged spots. Fireclay brick usually has lower thermal conductivity, so it insulates better. The best choice depends on the job, the shape needed, and how much heat there will be.

When looking at thermal conductivity, people should check these things:

What the material is made of

How many air spaces and how dense it is

The temperature it will face

How big the grains are

How much water is inside

If there are any extra additives

The table below shows how fireclay brick compares to other refractory bricks and insulating castables.

| Material Type | Typical Thermal Conductivity (W/m·K) | Max Service Temp (°C) | Key Features |

|---|---|---|---|

| Fireclay brick | 0.13–0.14 | 1000–1400 | Good insulation, low cost |

| High-alumina brick | 1.3–2.0 | 1400–1800 | High strength, higher cost |

| Insulating castable | 0.15–0.25 | 1000–1200 | Easy to shape, moderate strength |

| Silica fire brick | 1.7–1.9 | 1700 | High temp, less insulation |

| Magnesia fire brick | 1.5–2.5 | 1800 | Basic lining, strong |

Fireclay brick is good because it has low thermal conductivity and gives strong insulation. High-alumina and magnesia fire bricks are stronger but let more heat out. Insulating castables can be shaped easily but may not last as long as fireclay bricks. Each type of fire brick is best for different jobs in furnaces, kilns, and other hot places.

Picking the right fireclay depends on what the job needs. Every use of fireclay bricks is a bit different. Builders want bricks that keep heat inside and save energy. They look for bricks with low thermal conductivity. This means less heat gets out. Porosity is important too. Tiny air pockets help stop heat from escaping.

A good fireclay brick must be strong and not break under pressure. It should keep its size even when it gets hot. Storing less heat at low temperatures helps save energy. High purity is needed. Bricks with fewer metals or iron last longer and work better.

Bricks must fit together tightly. This stops heat from leaking out. The working temperature should stay below 1350°C. Bricks must keep their shape under heavy weight. They also need to resist changes from chemicals at high heat. Lower bulk density means less heat is stored. This makes machines use less energy. In electric furnaces, bricks must block both heat and electricity.

Low thermal conductivity helps keep heat in.

Porosity saves energy by trapping air.

Strong bricks do not crush or change shape.

Low-temperature heat storage saves energy.

High purity means fewer bad materials inside.

Bricks must fit tightly with no gaps.

The right use temperature keeps bricks safe.

Bricks must handle heat and chemicals well.

Lower bulk density means less heat is stored.

Bricks must block electricity in electric furnaces.

How fireclay is made can change how it works. Additives like lime or slags can change porosity and density. This helps make bricks for different jobs. Each factory may need a different mix of insulation and strength.

When people pick fireclay, they look at how well it works and how much it costs. Fireclay bricks are a good deal. They cost less than many other insulation materials. Making lots of bricks and using local materials keeps prices low. Some factories make up to 150,000 tons each year. This makes each ton cost about 150 dollars.

| Aspect | Fireclay Bricks (Kerui) |

|---|---|

| Price per ton | About 150 USD |

| Raw Material Cost Factors | Local pure materials lower the price |

| Manufacturing Scale | Big factories make more and lower the cost |

| Automation & Efficiency | Machines help lower labor and mistakes |

| Sales Model | Selling direct from the factory saves money |

Fireclay bricks may cost more at first than some light bricks. But they save money over time. Their low thermal conductivity means furnaces lose less heat, up to 30% less. This saves fuel and helps machines last longer. Spending more at first saves money later on energy and repairs.

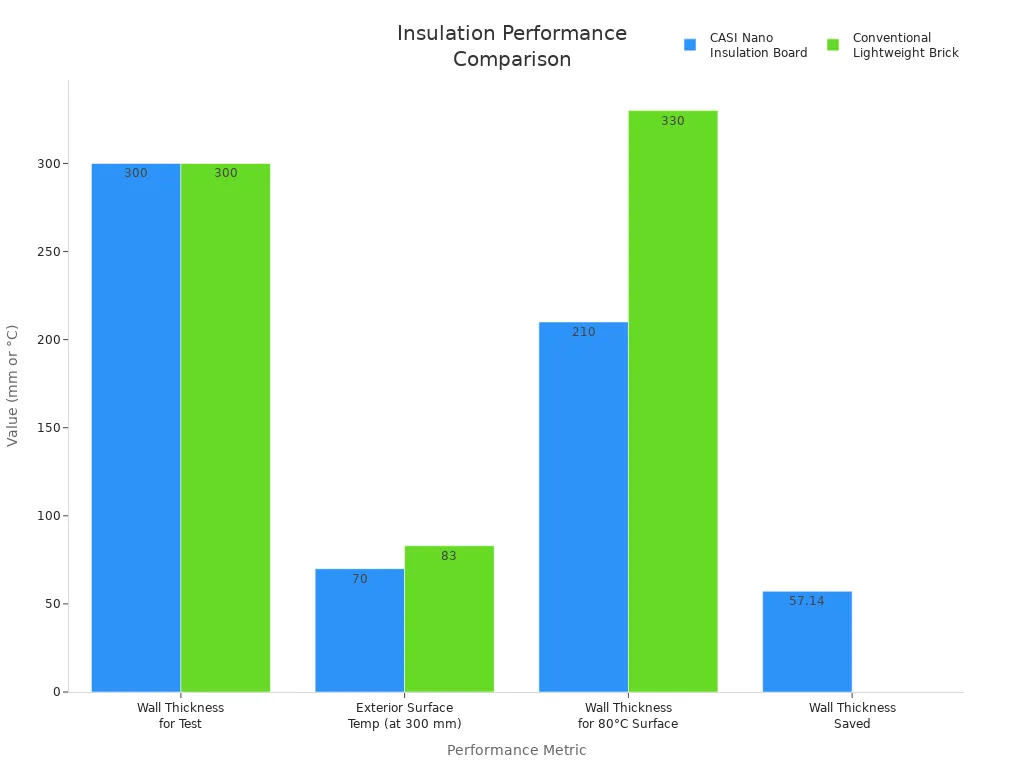

Some new materials, like CASI Nano Insulation Board, insulate even better. These boards keep outside walls cooler with less thickness. For example, a 300 mm nano board wall stays at 70°C. A light brick wall of the same size gets to 83°C. To reach 80°C, the nano board only needs to be 210 mm thick. This saves material.

Still, fireclay is used a lot in many industries. It works well in furnaces and other hot places. The balance of cost and performance makes fireclay a smart choice for companies that want to save money and energy.

Tip: Always pick the fireclay brick that fits the job. Think about both the price now and the money you will save later from using less energy and having strong bricks.

Knowing about thermal conductivity helps people pick the best fireclay for insulation. Fireclay with low thermal conductivity keeps heat from escaping. This helps save energy in kilns and furnaces. Fireclay gives strong insulation and can handle high heat. It is also tough and does not break easily. People should look at different fireclay types before choosing one. Fireclay with more air spaces insulates better. To learn more, readers can look at datasheets, test results, and articles about fireclay. Fireclay is still a top choice for safe and long-lasting insulation.

A fireclay brick is made from fireclay. It can take very high heat. It helps keep furnaces, kilns, and ovens hot. Fireclay brick is used in many industries. It keeps heat inside and lasts a long time.

Fireclay refractory brick can handle much higher heat. It resists heat, chemicals, and sudden temperature changes. Regular brick cannot work in furnaces or kilns. Fireclay refractory brick stays strong and safe in these places.

Many companies sell fireclay brick online. Yufeng Refractory has different types for sale. Buyers can pick the size and shape they need. Always read the product details before buying.

Thermal conductivity shows how well fireclay brick stops heat. Low thermal conductivity means better insulation. This saves energy and keeps furnace outsides cooler and safer.

Yes, fireclay brick can be used at home. People use it in fireplaces, pizza ovens, and wood stoves. Fireclay brick keeps heat inside and protects walls from high heat.