Views: 0 Author: Site Editor Publish Time: 2025-08-29 Origin: Site

Insulating fire brick keeps heat inside hot spaces. Workers use it for thermal insulation in kilns, furnaces, and ovens. Installing it the right way keeps people and buildings safe. It helps stop dangers like heat burns, acid gas leaks, fly ash breathing, and fire. Sometimes, accidents happen when workers hurry or skip safety steps. This can cause injuries or problems.

Heat can hurt people near boilers.

Acid gas leaks can hurt lungs and eyes.

Coal dust and fly ash make it hard to breathe and easy to slip.

Bad installation can cause fires or sparks.

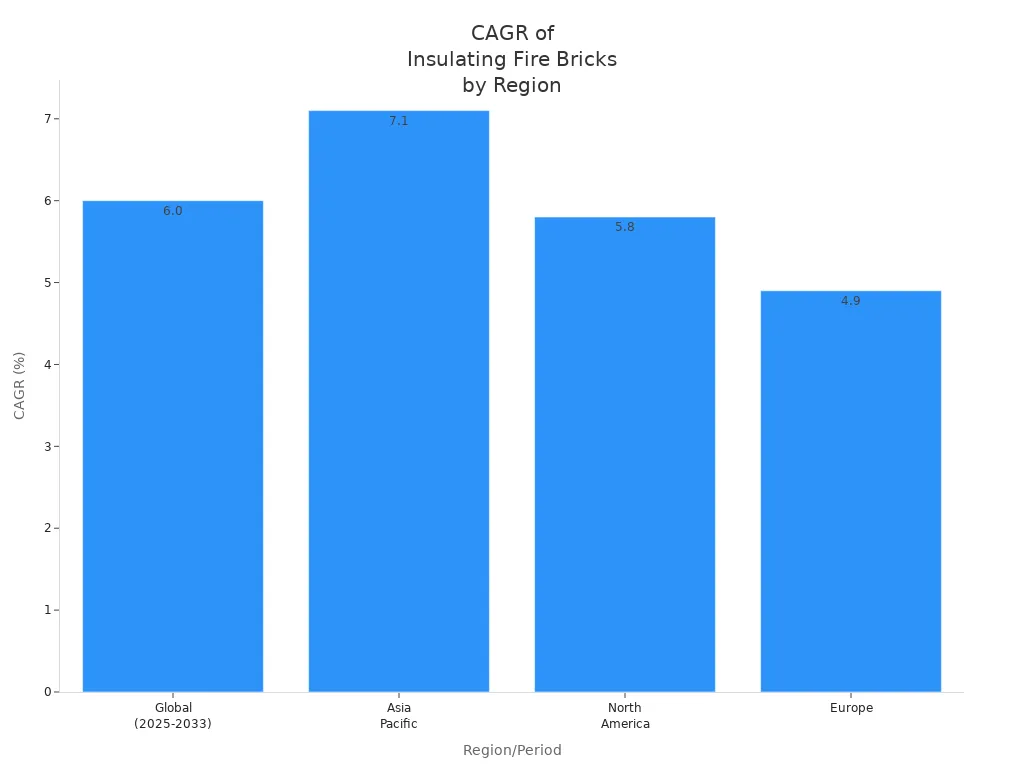

The world market for insulating fire brick is growing. This shows people want safe and good solutions.

Insulating fire bricks help keep heat inside kilns, furnaces, and ovens. This saves energy and keeps people and buildings safe from heat and fire.

Pick the right insulating fire brick for your needs. Think about heat, chemicals, and strength to make sure it is safe and lasts a long time.

Use the correct steps to install the bricks. Use the right tools, wear safety gear, and use high-temperature mortar. This helps stop cracks, bad insulation, and accidents.

Check and take care of insulating fire bricks often. Clean them, look for cracks, and fix damage early. This keeps them safe and working well.

Do not make mistakes like laying bricks unevenly, not cleaning surfaces well, or not anchoring bricks tightly. This helps the fire brick system work better and last longer.

Insulating fire brick is light and full of tiny holes. These holes trap air and slow down heat. This helps keep heat inside places like kilns and furnaces. The bricks are not heavy. They weigh about 0.8 to 1.0 grams per cubic centimeter. Because they have many holes, they keep heat from getting out. But they are not as strong as other fire bricks.

Note: More holes mean better insulation but less strength. You need to pick the right brick for each job.

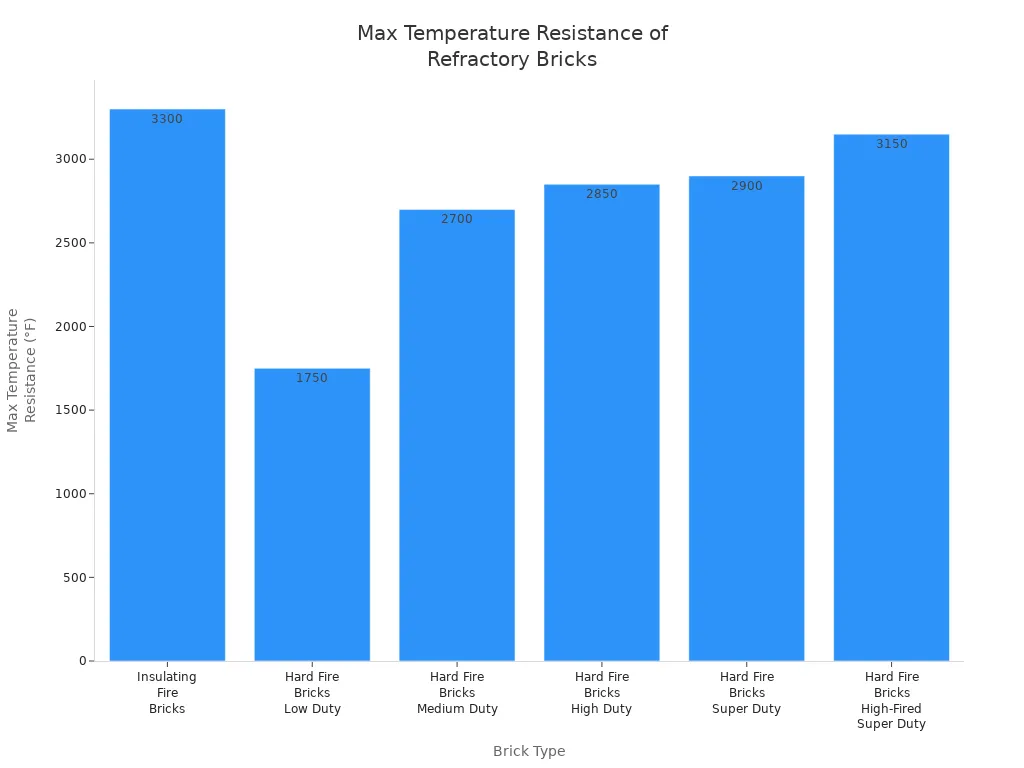

Insulating bricks can handle chemicals and quick temperature changes. They do not let much heat pass through. Their thermal conductivity is about 0.2 to 0.4 W/m·K at 350°C. This is lower than regular fire bricks. The table below shows how different fire bricks compare:

| Brick Type | Temperature Resistance Range (°F) | Density (g/cm³) | Porosity | Thermal Conductivity (W/m·K) | Notes |

|---|---|---|---|---|---|

| Insulating Fire Bricks | 2000–3300 | 0.8–1.0 | High | 0.2–0.4 | Best for insulation, not direct flame contact |

| Hard Fire Bricks (Low Duty) | Up to 1750 | >2.0 | Low | >1.0 | Used in fireplaces, chimneys |

| Hard Fire Bricks (High Duty) | Up to 2850 | >2.0 | Low | >1.0 | Used in kilns, boilers |

People make insulating bricks from clay, kaolin, alumina, mullite, and silica. The material changes how the brick handles heat and chemicals. More alumina makes more mullite and corundum. This helps the brick stand up to heat and chemicals. Bricks with over 71.8% alumina have both mullite and corundum. These bricks work well in very hot places.

There are different types of insulating fire brick:

Silica clay light insulation bricks have lots of tiny holes. They are light and keep heat in. They help save energy.

Lightweight mullite insulation bricks can handle quick temperature changes and chemicals. Their weight and holes depend on how they are made.

Alumina bubble bricks have bubbles inside. They are strong but still light. They are good for very hot places.

High-alumina poly-light bricks use pure materials. They have some holes and keep their shape well. They insulate well too.

You need to pick the right brick for the job. Think about heat, chemicals, and how much force the bricks will face. Each type has its own balance of insulation, strength, and lasting power.

Insulating bricks have many uses at work and at home. People use them to line kilns, furnaces, and ovens. They also work as insulation in hot places. These fire bricks keep heat inside. They help save energy and protect buildings from harm.

Factories use insulating bricks in lots of ways. Some main uses are:

Lining kilns for ceramics and pottery

Building furnaces for steel, glass, and aluminum

Making backup insulation in heat chambers

Protecting tools in petrochemical plants and power stations

Insulating fire bricks can handle very high heat, up to 1800°C. They are light and full of holes. This makes them easy to put in and shape for special furnace needs. These bricks do not crack when the heat changes fast. Many factories use them to stop heat loss and save fuel. They also help keep workers safe.

| Industrial Application | Performance Requirements |

|---|---|

| Steel and Metal Industry | High temperature resistance, chemical resistance, mechanical strength, thermal shock resistance |

| Glass Manufacturing | High temperature resistance, corrosion resistance, durability |

| Cement Production | High temperature resistance, thermal insulation, mechanical strength |

| Petrochemical Industry | Chemical resistance, high temperature resistance, durability |

| Power Generation | Thermal shock resistance, high temperature resistance, mechanical strength |

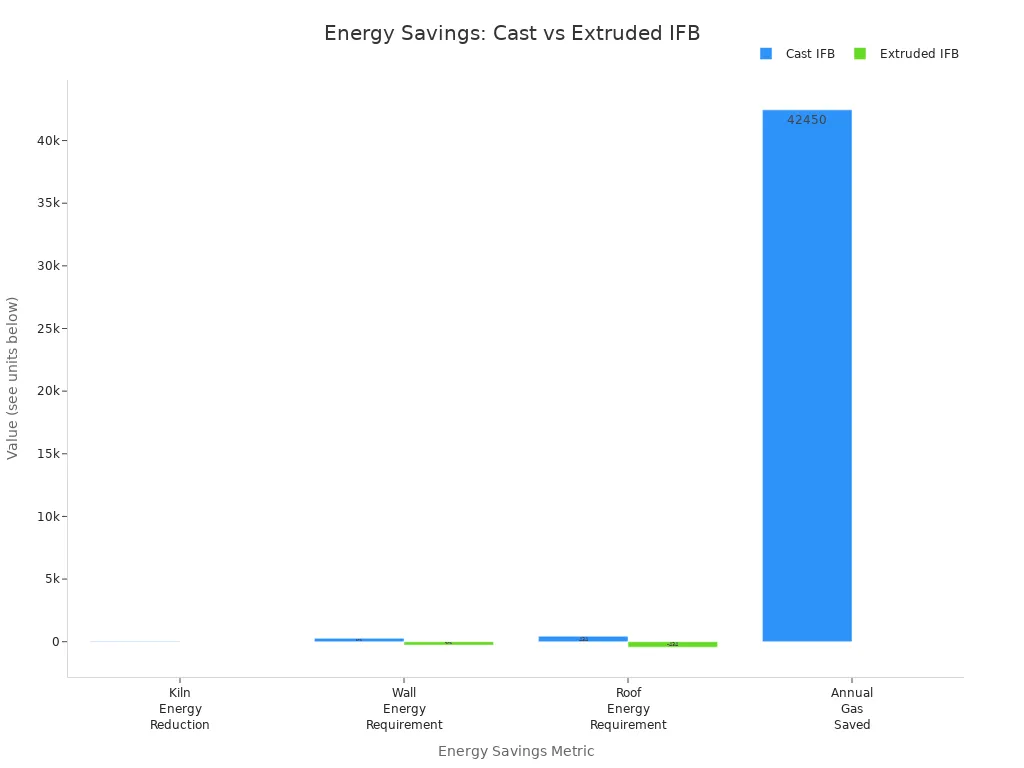

Insulating bricks help save energy in factories. For example, cast insulating fire bricks can cut kiln energy use by up to 38%. They keep furnace walls and roofs cooler. This means less heat gets out and workers are safer. The chart below shows how much energy these bricks can save in different furnace parts.

Insulating bricks are not just for big factories. Many people use fire bricks for home and garden jobs. Some main uses at home are:

Building outdoor fire pits and fireplaces

Making pizza ovens and barbecue grills

Lining wood stoves and small pottery kilns

These fire bricks keep heat inside the firebox. This makes cooking and heating outside safer and better. People like these bricks because they are easy to move, cut, and fit. For a simple fire pit, people put the bricks in a circle. They fill the bottom with sand or gravel. Then they use mortar to hold the bricks together. Bigger projects, like outdoor kitchens or pizza ovens, use fire bricks for fireboxes, smoke spaces, and chimneys.

Tip: Always choose fire bricks with the right heat rating and size for your job. This keeps you safe and makes your project last longer.

Insulating bricks make home jobs safer and save energy. They keep heat where it should be and protect things nearby from getting too hot.

Insulating bricks and refractory bricks do different jobs. Insulating bricks are light and full of tiny holes. This helps them keep heat inside kilns and ovens. Workers use them when stopping heat loss is important. Refractory bricks are much stronger and last longer. They hold up heavy things and do not wear out fast. These bricks are good for furnace floors and walls.

The table below shows how the two types compare:

| Aspect | Insulating Fire Bricks | Standard Refractory Bricks |

|---|---|---|

| Weight | Approximately 2 lbs per brick | Approximately 8 lbs per brick |

| Ease of Installation | Easier to handle, lighter | Heavier, harder to move |

| Cost | More expensive | Less expensive |

| Mechanical Strength | Lower robustness | Higher strength and durability |

| Typical Use | Insulation layers | Structural and wear-resistant applications |

| Thermal Properties | Superior insulation | Retain heat better due to higher mass |

Insulating bricks are about three times lighter than refractory bricks. This makes them easy to move and put in place. Refractory bricks are heavier and give more support. They last longer in tough spots.

Note: Insulating bricks are best for keeping heat in. Refractory bricks are best for strength and holding heat.

Insulating bricks help save energy in many ways. They do not let much heat escape from furnaces and ovens. This means people use less fuel. Workers see lower energy bills because of less heat loss. Refractory bricks are strong but do not insulate as well. Their dense build lets more heat out.

Many companies use light insulating bricks for cheaper brands. These bricks are quick and safe to install. Refractory bricks are used in top brands for tough jobs. They last a long time in hard places. Insulating bricks also cost less to ship because they weigh less.

Insulating bricks:

Keep heat in very well

Lower energy costs

Are easy to install

Weigh less for shipping

Refractory bricks:

Are very strong

Last a long time with heavy use

Hold heat well because they are heavy

Both brick types have special uses. Pick the right one for your job. Think about how much heat, strength, and energy savings you need.

Getting ready is important for a safe job. Workers must pick the right insulating fire brick. They look at thermal conductivity, density, and porosity. Lighter bricks keep heat in better. Heavier bricks are stronger. Picking the right one helps the bricks last longer.

Before starting, workers gather all their tools and supplies:

Trowel for spreading mortar

Brick saw or angle grinder for cutting fire bricks

Level and measuring tape for accuracy

Rubber mallet for gentle tapping

Chalk for marking layout lines

Bucket and clean water for mixing mortar

Wire brush for cleaning surfaces

Safety gear: gloves, goggles, dust mask

Workers clean the base so it is flat and dry. They use chalk to mark lines for the bricks. Dry fitting the bricks helps check if they fit well. This step helps stop mistakes and saves time.

Tip: Always look for cracks or chips in the fire bricks before you start. Broken bricks make the finished job weaker and less safe.

Safety is very important for every job with refractory bricks. Workers must wear PPE like masks, safety glasses, and gloves. They also need hearing protection and special clothes. These items protect from dust, sharp edges, and flying bits.

To keep dust low, workers use special tools. Power tools with dust collectors help too. Good airflow keeps the air clean. Workers clean tools with HEPA vacuums or wipes. They pick up scrap right away to stop slips and falls.

Fireproofing and fire stopping keep the building safe from fire. If it is loud, workers must follow hearing safety rules. Safety steps help keep everyone healthy and safe at work.

Note: Never skip safety steps. Even a little dust or debris can hurt your lungs or cause injuries.

Putting in fire bricks takes careful work. Workers follow these steps for the best results:

Dry Fit: Lay out the fire bricks without mortar to check the pattern and spacing.

Mix Mortar: Use high-temperature refractory mortar. Mix it as the instructions say. The mortar should be smooth and easy to spread.

Apply Mortar: Spread a thin, even layer of mortar (1/16" to 1/4") on the brick surfaces. Do not use too much. Thick joints can crack.

Lay Bricks: Start in a corner. Place each fire brick in its spot. Press gently and tap with a rubber mallet. Check each row with a level.

Cut Bricks: Use a brick saw or angle grinder to cut bricks if needed. Always wear safety gear when cutting.

Clean Joints: Wipe off extra mortar with a trowel or brush before it dries.

Check Alignment: Use a level and measuring tape to keep rows straight and even.

Allow to Cure: Let the mortar dry slowly. Do not heat it up fast. Quick heating can cause cracks.

The glue you use matters. Refractory mortar is best for new jobs and strong joints. Furnace cement is good for repairs and metal-to-brick spots. High-temperature silicone seals joints that need to move. The table below shows how each adhesive is different:

| Adhesive/Mortar Type | Temperature Rating | Suitable Joint Thickness | Ideal Application |

|---|---|---|---|

| Refractory Mortar | Up to 2700°F | 1/16" to 1/4" | New firebrick construction, structural joints |

| Furnace Cement | 2000°F to 3000°F | Up to 1/8" | Repairs, metal-to-masonry bonding, stove pipe seals |

| High-Temperature Silicone | Up to 2300°F | Under 1/16" | Expansion joints, sealing, flexible applications |

Refractory mortars use fireclay, alumina cement, and special rocks. These stay strong when hot. They do not break after heating and cooling many times. Once dry, water cannot wash them away. This keeps the joints safe from water.

After all the bricks are in, workers check the job. They smooth the joints and clean the surface with a wire brush. Any loose mortar or dirt should be taken away. The mortar must dry all the way before using heat.

Workers look for gaps or uneven joints. They fill any spaces with refractory mortar. A final check makes sure all bricks are tight and level. The area should be clean and free of scraps.

Tip: Let the finished job dry and cure for at least 24 hours. Heat it up slowly to stop cracks from forming.

Good finishing helps the fire brick job last longer. Checking and fixing the bricks often keeps everything safe and working well.

Many workers make mistakes when they put in insulating fire brick. These mistakes can make the job unsafe or not work well. The most common problems are not cleaning the surface, laying bricks unevenly, and not anchoring bricks well. Sometimes, workers forget to pack non-shaped refractory materials tightly. These mistakes can cause cracks, bad insulation, or the bricks to fail early.

| Common Mistake | Description & Example | Consequences |

|---|---|---|

| Improper surface treatment | Furnace wall not cleaned; oil and dust remain. Example: refractory fell off in a steel mill furnace. | Premature refractory falling off, poor bonding under high temperature and pressure. |

| Bricklaying errors | Uneven ash joints; thick joints cause stress. Example: cracks inside kiln, insulation loss. | Cracks, insulation degradation, reduced service life. |

| Insufficient compaction | Non-shaped refractory poured without vibration. Example: voids form, metal liquid penetrates. | Accelerated erosion, need for early repair. |

| Poor anchoring | Substandard anchor nails used. Example: large area of refractory falling off in a boiler upgrade. | Safety hazards, long shutdown maintenance. |

Other things can also make bricks fail. Fast temperature changes can cause thermal stress. Bricks can get damaged if handled roughly. Chemicals can eat away at the bricks. Slag or ash can build up and hurt the bricks. Workers need to avoid these mistakes to keep bricks strong and safe.

Experts have some good advice for putting in insulating fire brick. Pick bricks with the right temperature rating for each layer. Put higher-rated bricks on the hot side. Use lower-rated bricks for insulation. Adding insulating boards and mineral wool helps block heat and lets bricks expand.

Planning is very important. Workers should do rebricking during planned shutdowns. Get all tools ready before starting. Go over lockout steps and work with the maintenance team to stay safe. Let refractory materials cure the right way to stop them from breaking. Always add expansion joints so the bricks can move and not crack.

Keep joints clean and sealed tight. High-temperature fiber expansion joints stop gas leaks and hot spots. Make sure floors are level and the design is good to stop walls from bending. Pick good refractory bricks and materials for longer use. Check the bricks often and fix problems quickly to keep everything working.

Tip: Pick bricks for quality and reliability, not just price. Good refractory bricks protect equipment and save money in the long run.

Taking care of insulating fire brick helps it last a long time. Regular checks stop damage and keep heat inside kilns, ovens, and fireplaces. Workers should do these things to help fire brick last:

Look at bricks often for cracks or loose pieces.

Clean off soot, ash, moss, or mildew with a soft brush and mild soap.

Put sealants on bricks to keep out water and weather. This stops moisture from getting in.

Fix small cracks with patching stuff like Castable Gunmix. Fast fixes stop bigger problems.

Take out creosote and other build-up from the firebox and chimney. This keeps air moving and lowers fire danger.

Keep dampers and insulation in good shape to help the system work better.

Do maintenance before busy times, like winter, to stay safe and keep things working well. If the chimney liner is damaged, fix it fast to stop chimney fires or carbon monoxide leaks.

Tip: Get a pro to help with hard repairs or if you are not sure what to do.

Checking fire brick often helps find problems early. Workers should use a simple plan to keep fire brick strong:

Daily: Look at the hearth and fireplace for loose bricks or trash. Take out ashes after every use.

Weekly: Clean inside and outside bricks. Watch for wet spots, leaks, or wear.

Seasonal: In fall, check the system before using it a lot. In spring, clean deeply and look for cracks or broken mortar.

Annual: Have a pro check everything. Experts use tools like video cameras to find hidden problems in refractory bricks and fire clay insulating bricks.

Early damage signs are cracks from heat, pieces breaking off from water, and mortar falling apart. Cleaning and checking often keeps lightweight insulating fire bricks and fire brick structures strong.

| Inspection Interval | What to Check | Action Needed |

|---|---|---|

| Daily | Loose bricks, debris, ashes | Remove and clean |

| Weekly | Soot, moisture, leaks | Clean, check for damage |

| Seasonal | Cracks, mortar, chimney cap | Repair, deep clean |

| Annual | Structural issues, hidden damage | Professional assessment |

Note: Finding problems early and fixing them fast keeps insulating fire brick safe and working well.

Knowing how to use insulating fire brick and putting it in the right way keeps kilns, ovens, and furnaces safe. It also helps them work well. When workers do things the right way, they get many good results:

If you install and care for the bricks, you pay less for energy and repairs.

Special insulating fire brick lasts a long time and does not need to be changed often.

| Improvement Category | Description |

|---|---|

| Enhanced Process Efficiency | Heating up and cooling down is faster. This saves time and gives better control. |

| Increased Lining Lifespan | The bricks protect equipment from heat damage. This makes refractory bricks last longer. |

| Improved Working Environment | The outside stays cooler. This keeps workers safer and more comfortable. |

Using these tips makes every fire brick job work better and last longer.

Insulating fire brick holds heat because it has many tiny holes. Refractory bricks are strong and do not wear out fast. Insulating fire brick is best for keeping heat in. Refractory bricks are good for heavy jobs and last longer.

Yes, lightweight insulating fire bricks keep heat inside pizza ovens. They help food cook evenly. These bricks also make ovens safer by keeping the outside cool.

Workers should check fire clay insulating bricks every season. Regular checks help find cracks or loose bricks early. This keeps ovens, kilns, and fireplaces safe and working well.

Refractory mortar is best for putting in insulating fire brick. It can handle high heat and keeps joints strong. Furnace cement is good for fixing and sealing metal-to-brick spots.

Insulating fire brick needs regular cleaning and checking. Workers should take away ash, soot, and dirt. Fast repairs for cracks help fire brick last longer and keep heat inside.