Views: 5 Author: Site Editor Publish Time: 2025-08-08 Origin: Site

Choosing the right insulating fire brick is important for hot projects. Insulating firebrick is mostly made from alumina and silica. It gives strong heat protection and keeps kilns, ovens, and fireplaces safe. The way the firebrick is made changes how well it works. More alumina makes the brick resist fire better and makes it heavier. This is good for tough places.

| Alumina Content | Key Benefit |

|---|---|

| 48%-60% (Grade III) | Good for holding in heat |

| 60%-75% (Grade II) | Better at stopping fire |

| >75% (Grade I) | Best for heat and strength |

When you pick firebrick, look at the temperature rating. Also check density, how well it holds heat, chemical resistance, price, and how easy it is to put in. Silica insulation bricks also help save energy in many places.

Pick insulating fire bricks by checking heat resistance, weight, and porosity. This helps you get good insulation and strong bricks for your project. - Find bricks with a temperature rating above your highest heat. This keeps your equipment safe and helps it last longer. - Use lightweight insulating fire bricks if you want easy handling. These bricks also help save energy in kilns, ovens, and fireplaces. - Put the bricks in place carefully. Make sure the joints are tight and sealed well. This stops heat from escaping and helps the bricks last longer. - Check and take care of fire bricks often. Clean them and fix any cracks. This keeps insulation working well and makes sure everything stays safe.

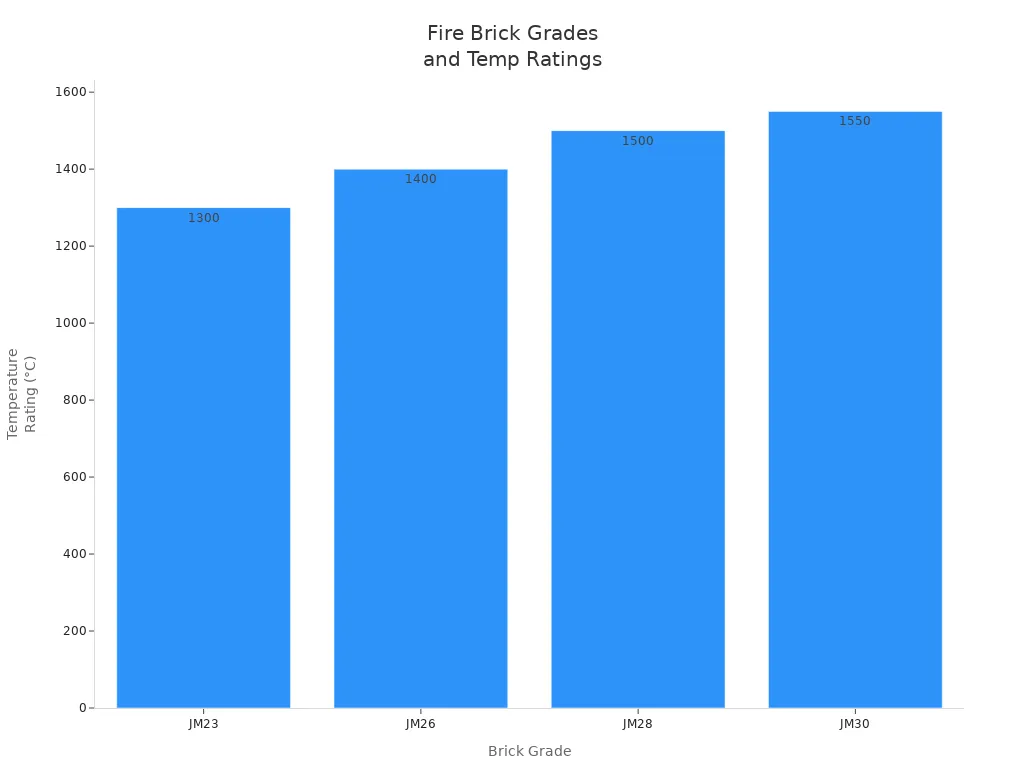

Temperature rating is a key feature of insulating firebrick. It shows how much heat the firebrick can take before breaking. In factories, insulating fire brick can handle from 2370°F to 2820°F. Some bricks, like IN-26, can go up to 2600°F. These are used in kilns, furnaces, and glass making.

| Grade | Temperature Rating |

|---|---|

| JM23 | 1300°C (2370°F) |

| JM26 | 1400°C (2550°F) |

| JM28 | 1500°C (2730°F) |

| JM30 | 1550°C (2820°F) |

Manufacturers use special powders and fillers to make insulating firebrick. They shape the bricks with vacuum compression molding. Then, they heat the bricks at high temperatures. This makes the bricks strong and even. The firebrick does not let heat move through it easily. It also does not crack when heated and cooled many times. These features help the firebrick last longer and keep things safe.

Tip: Pick a firebrick with a temperature rating higher than your highest temperature. This helps your equipment last longer and stay safe.

Density and porosity are important for how insulating fire brick works. These bricks are lighter than regular bricks. They are easy to move and use. High porosity means there are lots of tiny air spaces inside. These air spaces stop heat from moving through the brick.

| Aspect | Effect of Porosity on Insulating Fire Bricks |

|---|---|

| Definition | Porosity is the volume proportion of pores in the brick. |

| Thermal Conductivity | Increased porosity generally reduces thermal conductivity, improving insulation. |

| Mechanical Strength | Higher porosity decreases strength due to reduced solid cross-section and stress concentration at pores. |

| Durability | Excessive porosity can lead to thermal stress, thermal shock cracks, and reduced service life. |

| Optimal Porosity | Must balance sufficient strength with good insulation; too low porosity reduces insulation, too high reduces strength. |

| Types of Pores | Open, closed, and through pores affect properties differently. |

| Bulk Density | Porosity inversely correlates with bulk density; higher porosity means lower density. |

| Design Implication | Porosity is critical in designing bricks to achieve desired thermal insulation performance. |

Most insulating firebrick has porosity between 40% and 80%. This makes the brick light and helps keep heat inside. But too much porosity can make the brick weak. Makers must balance porosity and strength for high heat places.

Thermal conductivity tells how fast heat moves through a material. Insulating fire brick has low thermal conductivity. This means heat does not escape quickly. It keeps furnaces and kilns hot inside and cool outside.

| Grade/Density | Thermal Conductivity (kcal/m·h·°C) | Converted to W/m·K (approx.) |

|---|---|---|

| Low-density insulating fire bricks | 0.2 - 0.25 | 0.23 - 0.29 |

| Higher-density insulating fire bricks | ~0.4 | ~0.47 |

Insulating firebrick stops heat loss better than dense bricks.

| Brick Type | Thermal Conductivity (W/m·K) at 350±25°C |

|---|---|

| Insulating Fire Bricks | 0.2 - 0.4 |

| Dense Refractory Bricks | Above 1.0 |

Low thermal conductivity saves energy and makes work more efficient. Light insulating fire bricks heat up and cool down faster. This can help lower costs.

Insulating firebrick needs to resist chemicals in tough places. These bricks are used in furnaces with strong chemicals and lots of heat. High alumina insulating fire brick resists heat shock, chemicals, and wear. Most insulating firebrick can take up to 3000°F. This makes them good for very hot jobs.

Insulating fire bricks resist many chemicals and heat cycles.

High alumina firebrick is best for chemical attack and wear.

These bricks are not as strong as dense bricks and can wear out with heavy use.

Their softness and high porosity make them easy to shape but also easier to erode.

To test chemical resistance, experts heat the firebrick many times at high temperatures. They check the brick’s structure after testing. This helps pick the right brick for each job.

Note: Make sure your insulating fire brick matches the chemicals in your process. This helps your equipment last longer and stay protected.

There are many kinds of refractory bricks. Each kind uses different materials and has special jobs. Most firebrick is made with alumina and silica. Other minerals can change how the brick works. Mullite insulation brick uses mullite crystals. This helps it stay strong when heated. Lightweight clay insulation bricks use fire clay. They have lots of tiny air pockets inside. Silica insulation brick has a lot of silica. This makes it very good at stopping fire. High alumina insulation brick has more alumina. It works better in very hot places.

Mullite insulation brick

Lightweight clay insulation bricks

Silica insulation brick

High alumina insulation brick

The table below lists common types and their features:

| Type of Refractory Brick | Service Temperature (℃) | Key Characteristics and Composition |

|---|---|---|

| High Strength Lightweight Refractory Brick | < 1000 | Includes diatomite brick, expanded perlite brick; used for insulation layers. |

| Lightweight Refractory Brick | 1000 - 1500 | Includes lightweight fireclay brick, lightweight silica brick, lightweight high alumina brick, mullite insulation brick. |

| High Temperature Refractory Brick | > 1500 | Includes lightweight corundum brick, alumina bubble brick, zirconia bubble brick; used for super high temperature. |

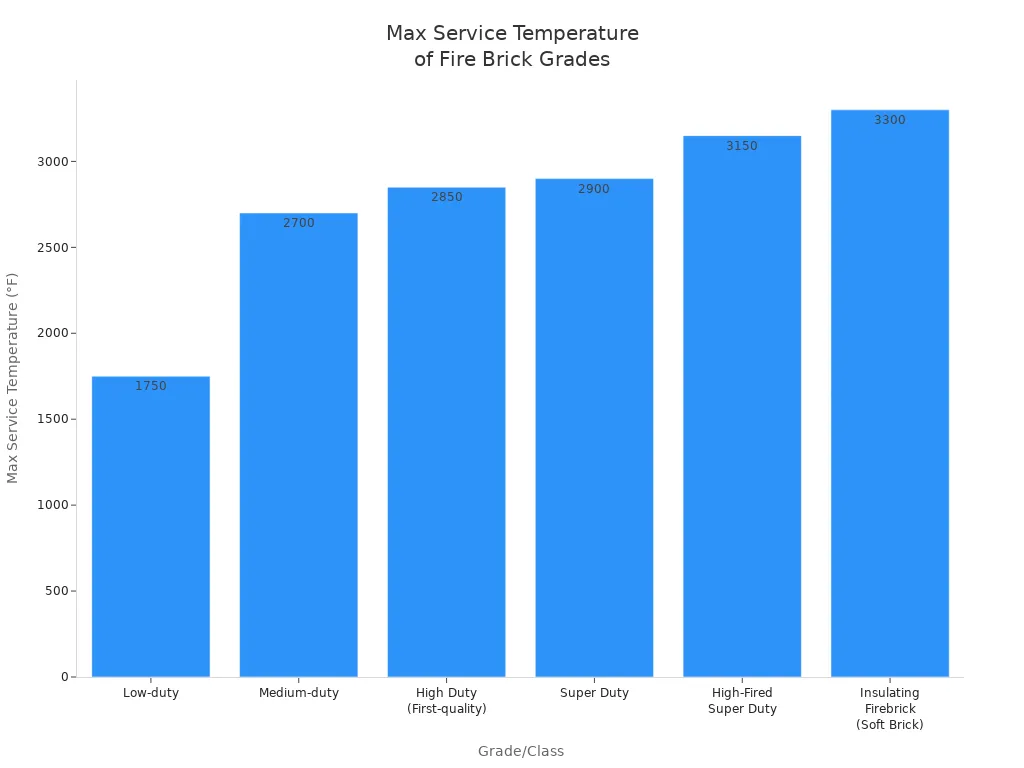

Refractory bricks come in different grades and classes. These depend on how much alumina they have and what they are used for. Low-duty bricks have 24–26% alumina. They work up to 1750°F. Medium-duty bricks have 34–38% alumina. They can handle up to 2700°F. High duty and super duty bricks have even more alumina. They work in hotter places. High-fired super duty bricks have less porosity. They are stronger and resist chemicals. Insulating firebrick is also called soft brick. It is light and has many air pockets. This makes it good for insulation. But it is not good for direct flame.

| Grade/Class | Alumina Content (%) | Max Service Temperature (°F) | Density/Type | Key Features and Applications |

|---|---|---|---|---|

| Low-duty | 24–26 | Up to 1750 | Hard, dense | Used for chimneys. |

| Medium-duty | 34–38 | Up to 2700 | Hard, dense | Used for backup linings, kilns, chimneys. |

| High Duty | 36–40 | Up to 2850 | Hard, dense | Used in boilers, kilns, chimneys. |

| Super Duty | 40–44 | Up to 2900 | Hard, dense | Used for higher temperatures. |

| High-Fired Super Duty | 40–44 | 3000–3150 | Hard, dense, lower porosity | Stronger, resists alkali and carbon monoxide. |

| Insulating Firebrick | N/A | 2000–3300 | Lightweight, porous | Used for insulation, absorbs less energy. |

Insulating firebrick takes in half the energy of hard refractory bricks. This makes it great for electric kilns and liners.

Refractory bricks and firebrick are different in price, insulation, and strength. Fire bricks cost more. They use better materials and are denser. Refractory bricks, especially insulating ones, are lighter and cost less. Insulating firebrick does not let heat pass through easily. Its thermal conductivity is usually 0.05 to 0.3 W/m·K. This helps save energy. Dense refractory bricks have higher thermal conductivity and density. They are stronger but also heavier. Insulating firebrick is best for insulation layers. Dense refractory bricks are better for direct flame and wear.

| Property | Insulating Firebrick | Dense Refractory Bricks |

|---|---|---|

| Thermal Conductivity | Low (0.05–0.4 W/m·K) | Higher (>1.0 W/m·K) |

| Density | Low (0.3–1.2 g/cm³) | High (>2.0 g/cm³) |

| Refractoriness | Moderate (1400–1800°C) | Higher (above 1400°C) |

| Mechanical Strength | Lower | Higher |

| Cost | Lower | Higher |

| Main Usage | Insulation layers | Flame contact, abrasion |

A lightweight refractory brick is easy to put in place. It also makes buildings lighter. Refractory bricks come in many shapes and sizes. Some are straight, some are curved, and some are flat like tiles. This helps builders pick the right brick for each job.

Refractory bricks are very important in kilns and furnaces. Workers use insulating fire brick to cover the walls and roofs. These bricks help keep the inside hot and steady. This is needed for making ceramics or melting metals. Kilns must get very hot, sometimes over 2,000°F. Insulating fire brick can handle this heat and does not break easily. These bricks are light, so they are easy to put in. They also make the whole structure lighter. Less heat escapes, so the equipment uses less fuel. This saves energy and money.

Tip: Using insulating fire brick in kilns and furnaces keeps the temperature steady and helps save energy.

People use refractory bricks in ovens and fireplaces at home. These bricks keep heat inside the oven. This helps bake food better. In fireplaces, the bricks protect from high heat. Insulating fire brick helps ovens and fireplaces warm up fast and cool down quickly. This means less energy is wasted. Users save more energy. The bricks do not let much heat pass through. This keeps the outside cooler and makes homes safer.

Lightweight insulating fire bricks are simple to carry and put in.

Fire clay insulating bricks are strong and resist heat well.

Low heat storage lets ovens and fireplaces heat and cool faster.

Many factories need refractory bricks for safety and saving energy. Steel plants use insulating fire brick to line furnaces. This protects them from very high heat and damage. Chemical factories use these bricks in reactors. The bricks resist heat and strong chemicals. Power plants use refractory bricks in boilers. This helps stop heat from escaping and makes them work better. Using insulating fire brick in hot equipment keeps heat where it is needed most and saves energy.

| Industry | Application Example |

|---|---|

| Steel and Metallurgy | Lining furnaces for melting and cleaning metals |

| Chemical Processing | Lining reactors for safe and good chemical reactions |

| Power Generation | Lining boilers to stop heat loss and save energy |

| Ceramics and Glass | Lining kilns for even product quality |

Picking and putting in insulating fire brick in homes takes planning. Homeowners and builders need to pick the right brick for each job. Here are some easy steps to follow:

Analyze Requirements

First, they figure out what the project needs. They look at how hot it will get, how much weight the bricks must hold, and if there are any chemicals. For example, a pizza oven needs lightweight insulating fire bricks that keep heat well. A fireplace may need fire clay insulating bricks because they are stronger.

Select Materials

Next, they pick the best refractory bricks for the job. Alumina-silicate bricks keep heat in and do not break from quick temperature changes. Fire clay insulating bricks are good for medium heat. Lightweight insulating fire bricks are best where you need easy handling and fast heating.

Design and Manufacture

Then, they plan the shape and size of the bricks to fit the space. Special ways of making bricks, like pressing them hard and firing them in special ovens, make the bricks stronger. Some bricks have custom shapes or fit together like puzzle pieces. This makes them easier to put in and helps keep heat inside.

Quality Control

They test each brick to see if it holds heat and is strong. Tiny particles, called nanoparticles and nanofibers, can make the bricks even better. This makes sure the insulating fire brick is safe and works well.

Prepare the Surface

Before putting in bricks, they clean the area and check if it is strong. Getting the space ready helps the bricks stick well and work better.

Install Bricks

They use the right mortar and joint materials. Some bricks come pre-cut or have special edges that fit together. This stops heat from leaking out and makes the job faster. They seal the joints well so heat does not escape.

Cure and Inspect

After putting in the bricks, they let them dry and cure. This takes out water and makes the bricks stronger. They check the bricks often to keep the insulation working and safe.

Tip: New options and better technology, like eco-friendly materials and stronger bricks, make insulating fire brick a smart pick for homes today.

Good installation helps fire brick work best. Builders and homeowners can use these tips:

Think about the size of the insulating fire brick and how thick the joints are. Thin joints help stop heat loss.

Use pre-cut bricks and bricks that lock together for lightweight insulating fire bricks. These make the job faster and keep heat in.

Be gentle with fire clay insulating bricks and other refractory bricks so they do not break.

Leave space for the bricks to get bigger when hot. This stops cracks and helps the bricks last longer.

Seal all joints well. Good seals keep heat inside and save energy.

If you can, hire pros to put in the bricks. Experts make sure the job is safe and done right.

Make it easy to swap out bricks later. Plan so you can change broken bricks without taking out all the others.

Checking and fixing bricks on time keeps insulating fire brick safe and working well.

Insulating fire brick gives good value for homes over time. A pack of eight insulating fire bricks (1.75" x 4.5" x 9", for 2500°F) costs about $72.10. This price is good for home jobs like pizza ovens, fireplaces, kilns, and furnaces.

| Product Type | Pack Size | Price (USD) | Application Examples |

|---|---|---|---|

| Insulating Fire Brick | 8 | $72.10 | Pizza ovens, fireplaces, kilns |

| Lightweight Insulating Bricks | Varies | Varies | Home ovens, fireboxes |

| Fire Clay Insulating Bricks | Varies | Varies | Fireplaces, chimneys |

Taking care of insulating fire brick helps it last longer and work better. Homeowners should:

Clean bricks often with a soft brush or vacuum to get rid of dust.

Check for cracks, worn spots, or loose bricks. Finding problems early stops bigger issues.

Fix or swap out broken bricks right away. This keeps insulation and safety strong.

Use special coatings to make bricks tougher and last longer.

Watch the temperature to stop overheating and early damage.

Keep extra bricks in a dry place so they do not get wet.

Letting bricks cure before use makes them stronger and helps insulation. Not taking care of bricks can make them fail too soon.

Insulating fire brick, lightweight insulating fire bricks, fire clay insulating bricks, and other refractory bricks help homes save energy, stay strong, and be safe from fire. With regular care and good installation, homeowners can enjoy these benefits for many years.

Picking the best insulating fire brick needs you to think about a few things.

How well the brick holds heat, how heavy it is, and how many tiny holes it has can change how much energy you save and how good the insulation is.

What you use the brick for matters too. Kilns and fireplaces need different kinds of fire brick or lightweight insulating fire bricks.

Looking at datasheets helps you see things like how strong the brick is and how much heat it can take.

Experts say you should talk to suppliers and try out samples before you decide. Making sure the insulating fire brick fits your needs helps stop problems early and keeps things safe.

Insulating fire brick keeps heat in with small air pockets. Dense refractory bricks are strong and can take direct flames. Insulating fire brick is best for insulation layers. Dense bricks work well where there is a lot of heat or wear.

Lightweight insulating fire bricks help pizza ovens stay hot. They make ovens heat up fast and cool down quickly. These bricks keep the outside cooler and help save energy.

Fire clay insulating bricks can handle high heat and protect walls. They stop heat from getting out and lower the chance of damage. These bricks also help keep homes safe from fire.

Homeowners should check refractory bricks every few months. They need to look for cracks, loose bricks, or worn spots. Checking often helps insulating fire brick last longer and keeps things safe.

Insulating fire brick usually costs less than dense fire brick. Lightweight insulating fire bricks and fire clay insulating bricks are a good deal for home use. The price depends on size, type, and how much heat they can take.