Views: 0 Author: Site Editor Publish Time: 2025-10-20 Origin: Site

When you pick the right kiln furniture, your ceramics fire evenly. This helps your pieces become strong. If you use the wrong support, your ceramics can crack or bend. Good kiln furniture keeps pottery safe. It makes sure each ceramic piece turns out right.

| Kiln Furniture Choice | Impact on Ceramic Results |

|---|---|

| Silicon carbide kiln furniture | Keeps heat even, so your work stays the same |

| Advanced industry adoption | Gives better results with smart kiln furniture choices |

| Effective kiln furniture | Lowers waste and stops pieces from bending |

You get more control over your ceramics when you choose well.

Picking the right kiln furniture helps heat spread evenly. This makes ceramics stronger and last longer. Check kiln furniture often for cracks or damage. This stops accidents and keeps your pottery safe when firing. Choose kiln furniture made from cordierite or mullite. These materials handle heat changes well and last a long time. Use the right supports and setters to keep ceramics in shape. This also helps you use kiln space better for good results. Buy good kiln furniture to save time, energy, and materials. This will help you make better pottery in the end.

You need kiln furniture when you fire pottery. These are shelves, posts, and supports inside the kiln. They hold your pottery steady while it fires. Without kiln furniture, pieces might touch the floor or each other. This can cause them to break or get damaged.

Here is a table that shows what kiln furniture does in ceramics:

| Function | Description |

|---|---|

| Support | Gives support to ceramics during firing. This keeps them stable and stops them from breaking. |

| Heat Distribution | Spreads heat evenly in the kiln. This helps all pieces fire the same way. |

| Space Optimization | Lets you fit more pieces in the kiln. This saves energy and space. |

| Protection | Stops ceramics from touching heating parts. This helps prevent damage. |

Kiln furniture does more than just hold pottery. It helps you use kiln space well and keeps ceramics safe.

Choosing the right kiln furniture helps your pottery turn out better. Good kiln furniture spreads heat evenly. This means every piece gets the same heat. Your pottery will have fewer cracks and warps.

Kiln furniture spreads heat so all ceramics fire the same.

It stops pieces from bending or changing shape.

Good refractory products lower the chance of fire or explosion.

Kiln posts keep everything steady and safe during firing.

Good airflow from kiln furniture helps fire pieces evenly and lowers defects.

Tip: Always look for cracks or damage in kiln furniture before firing. This keeps your pottery safe and helps stop accidents.

You depend on kiln furniture to protect your work. It helps your ceramics come out strong and nice. Using the right supports saves time, energy, and materials in ceramics.

Cordierite kiln furniture is common in ceramic studios. It can handle high heat and does not crack easily. Cordierite gives strong support to pottery during firing. Its low thermal expansion means shelves and posts keep their shape. Even if the temperature rises fast, they do not bend. This helps stop warping and keeps ceramics safe.

Here is a table that compares cordierite kiln furniture with other materials:

| Material | Thermal Expansion Coefficient (℃-1) | Thermal Shock Resistance | Suitable Temperature (°C) |

|---|---|---|---|

| Cordierite | 1.1×10⁻⁶ | Excellent | < 1300 |

| Mullite | 5.3×10⁻⁶ | Good | < 1300 |

| Corundum | N/A | Higher strength | Higher than 1300 |

Cordierite kiln furniture works best below 1300°C. You can use it for most pottery and ceramic work. It has great thermal shock resistance, so it does not crack when heating or cooling fast. Many artists like cordierite kiln furniture because it lasts long and gives steady results.

You should know the usual temperature range for cordierite kiln furniture. The highest service temperature is between 1250°C and 1400°C. This makes cordierite kiln furniture a safe pick for most ceramic firing jobs.

Mullite kiln furniture is another strong choice for firing ceramics. You find mullite shelves in kilns that get very hot. Mullite shelves can handle up to 1700°C. This makes them good for advanced ceramics and electronic parts. Mullite shelves stay the same size even when the kiln heats or cools quickly.

Here are some main benefits of mullite kiln furniture:

It can handle very high temperatures.

It does not crack or warp easily.

Mullite shelves keep their shape well.

They are strong and can hold heavy pottery.

Mullite shelves resist damage from chemicals.

You can count on mullite shelves for many firings. These shelves mix corundum and mullite for extra strength. Mullite shelves also resist oxidation, so they work well in kilns with lots of oxygen.

When you pick kiln furniture materials, you need to think about some key things. These things affect how well your kiln furniture works and how long it lasts. You want kiln furniture that can take high heat, not crack, and stay strong under heavy pottery.

Here is a table that shows important properties for kiln furniture:

| Property | Description | Example Material |

|---|---|---|

| Thermal Conductivity | Moves heat evenly across the shelf or post. | Silicon Carbide (SiC) |

| Thermal Stability | Stays strong at high temperatures. | Alumina (Al₂O₃) |

| Wear Resistance | Does not scratch or wear out when loading and unloading. | Silicon Nitride (Si₃N₄) |

| Corrosion Resistance | Lasts longer in places with lots of chemicals. | Zirconia (ZrO₂) |

| Resistivity | Stops electricity from passing through. | Aluminum Nitride (AlN) |

| Density | Can hold heavy pottery without bending. | Silicon Carbide (SiC) |

| Impact Resistance | Handles quick temperature changes and shocks. | Lithium Aluminosilicate |

You need kiln furniture with a high melting point and low thermal expansion. It should also have strong thermal shock resistance. Mullite shelves melt above 1850°C. They do not crack when the temperature changes fast. Mullite shelves also resist oxidation, so they work in kilns with lots of oxygen.

Thermal expansion and porosity are important for how long kiln furniture lasts. Cordierite kiln furniture has low thermal expansion and a very low creep rate. This means it keeps its shape and strength after many firings. Mullite shelves have higher thermal expansion and a moderate creep rate. But they still last a long time for high-temperature work.

Tip: If you want even heat and strong support, try silicon carbide kiln furniture for special projects. It moves heat well and keeps ceramics steady.

The materials you use for kiln furniture change how your pottery turns out. Cordierite kiln furniture gives great thermal shock resistance and works for most ceramics. Mullite shelves let you fire at higher temperatures and hold heavy loads. When you pick the right kiln furniture, you protect your ceramics and get better results every time.

You need shelves and posts for every kiln firing. These parts make the main frame inside the kiln. Cordierite shelves are used most often. They hold your pottery and help heat spread out. You can stack cordierite shelves at different levels. This lets you fit more pottery in one firing. Batts are flat plates that also work as shelves. You put your ceramics on batts to keep them safe from flames or dirt.

Here are the most common kiln furniture types in studios:

Kiln shelves like cordierite shelves and batts

Columns or posts

Beams and supports

Support accessories such as caps and collars

Push plates

Rollers

When you set up your kiln, put posts under each shelf. Posts hold up the shelves and batts so they stay steady. Using three posts instead of four can stop shelves from wobbling. This helps if your kiln floor is not flat. Place posts near the kiln walls to spread out the weight. This keeps your pottery stable. Never put posts right over heating elements. This stops hot spots and helps heat spread evenly.

Tip: Use thick posts for heavy pottery. Always lift the bottom shelf or batt a little. This lets heat move under your ceramics.

Setters and supports help keep pottery in shape during firing. You use setters for things that might bend, like plates or tiles. Batts can also be used as setters for flat pieces. When firing bone china or other fragile ware, setters keep the shape and stop bending. Supports let you stack pottery higher. This saves space and lets you fire more at once.

Setters and supports also help air move around your pottery. Good airflow means even heating and fewer problems. Vertical setters let you stack items and use kiln space better. They also stop warping. Setters and supports keep your pottery from sagging or changing shape, even when it gets very hot.

| Kiln Furniture Type | Main Function | Common Material |

|---|---|---|

| Cordierite shelves | Support and spread heat | Cordierite-mullite |

| Batts | Flat support for ceramics | Cordierite, mullite |

| Posts/Columns | Hold up shelves and batts | Cordierite, SiC |

| Setters | Hold shape, stop warping | Mullite, cordierite |

| Supports | Stack and steady ceramics | Cordierite, SiC |

You get the best results when you use the right kiln furniture for your needs. Cordierite shelves, batts, posts, and setters all work together. They protect your pottery and help you get strong, even results.

You need kiln furniture that can handle fast temperature changes. When you fire pottery, the kiln gets hot and cools down quickly. If the kiln furniture cannot take this, it might crack or break. This is called thermal shock resistance. You can check this by looking at what the furniture is made of. For example, silicon nitride can handle a 900°C drop. Alumina can take a drop between 170°C and 300°C. The Hasselmann Method tests this by heating a piece and then cooling it fast. After that, they see how strong it is. If the thermal shock resistance is high, your kiln furniture will last longer. It will also keep your pottery safe during many firings.

| Ceramic | Thermal Downshock Resistance (Δ°C) |

|---|---|

| Silicon Nitride | 900 |

| Zirconia | 400-500 |

| Silicon Carbide | 400 |

| Alumina | 170-300 |

Tip: Pick kiln furniture with high thermal shock resistance. This helps stop cracks and lets you use each piece more times.

You want kiln furniture that can hold heavy pottery without bending. Strong shelves and posts keep your pottery steady when firing. Makers test this by putting weight on the furniture until it breaks. They also heat it up to see if it changes shape. Good kiln furniture keeps its shape and strength after many firings. This means you do not have to buy new ones often. When you use strong supports, your pottery stays safe. Your kiln will also last longer.

Refractory performance testing checks for weight loss and shape changes at high heat.

Compressive strength testing finds out how much weight the furniture can hold.

Chemical analysis checks if the ceramic material is pure and strong.

There are signs to help you pick good kiln furniture for ceramics. The table below shows what to look for:

| Indicator | Description |

|---|---|

| Material Composition | Made from silicon carbide, cordierite, or alumina for high heat resistance. |

| Thermal Shock Resistance | Handles quick temperature changes without breaking. |

| Thermal Conductivity | Gives even heat distribution for better pottery results. |

| Mechanical Strength | Holds heavy pottery without bending. |

| Dimensional Stability | Keeps its shape at high temperatures. |

| Chemical Resistance | Does not react with glazes or clay. |

| Durability | Lasts through many firings. |

| Manufacturer Reputation | Trusted brands give better quality. |

| Compliance with Standards | Meets industry rules for ceramics. |

You should also check flexural strength and the highest working temperature. ASTM C1161 is a common test for flexural strength in ceramics. High flexural strength means your kiln furniture will not break under pressure. When you pick kiln furniture with these features, your pottery fires evenly. Your kiln will also need fewer repairs. Good heat flow and strong supports help your ceramic pieces turn out right every time.

You want your ceramics to be strong and look good. To do this, you must pick kiln furniture that fits your firing needs. Here is a simple guide to help you choose the right supports for your pottery:

Learn about your kiln. Each kiln needs different kiln furniture.

Check how hot your kiln gets. Some kiln furniture cannot take high heat.

Measure your pottery’s size and shape. Make sure shelves and posts fit your pieces.

Pick materials that work well with your clay and glaze.

Find kiln furniture with good thermal stability. This keeps your ceramics safe when heating or cooling fast.

Make sure shelves and posts can hold your pottery’s weight.

Choose designs that let air and heat move around your ceramics.

Think about the kiln’s atmosphere. Some materials work better in certain firing conditions.

Count how many times you fire. If you fire a lot, you need stronger kiln furniture.

Balance the price and how long the furniture will last.

Try new kiln furniture with a small batch first.

Ask experts or kiln makers if you need help.

Tip: Always test new kiln furniture with a small group of ceramics before using it for a full load.

You want kiln furniture that works well and does not waste money. The right choice saves time, energy, and materials in your studio.

Silicon carbide can hold heavy pottery at high heat. You can stack more pottery and fire bigger batches.

Strong kiln furniture, like R-SiC, lasts longer. You do not need to replace it as often.

Advanced materials, such as silicon carbide, use less energy and lower CO2 emissions.

Kiln furniture with high thermal conductivity spreads heat evenly. Your ceramics will have fewer problems and better quality.

Strong kiln furniture lets you fire faster. You can make more pottery without spending more money.

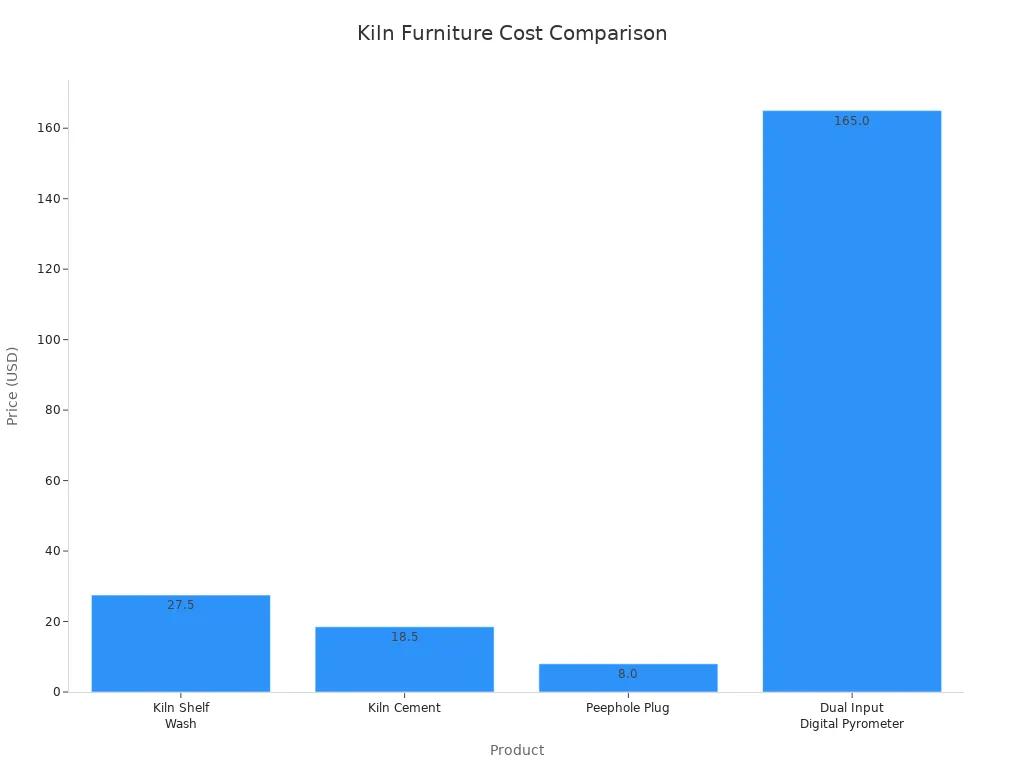

Here is a table with some kiln furniture products that save money for small studios and big ceramic businesses:

| Product | Description | Price |

|---|---|---|

| Kiln Shelf Wash | Makes kiln shelves last longer and helps remove glaze drips. | $27.50 |

| Kiln Cement | Fills cracks and chips in kiln refractory; ready to use. | $18.50 |

| Peephole Plug | Helps you check kiln conditions. | $8.00 |

| Dual Input Digital Pyrometer | Gives accurate temperature readings. | $165.00 |

| Pyrometric Cones | Checks firing quality; important for good results. | N/A |

When you pick kiln furniture that fits your needs and budget, you protect your pottery. You also make your studio work better and save money.

You help your ceramics turn out well when you pick kiln furniture carefully. If you choose supports made from pure materials, with good thermal shock resistance and strong mechanical strength, your pottery stays safe. Think about these things:

The material should be pure and stable.

It needs to move heat well and handle quick temperature changes.

It must be strong and keep its shape.

It should not get damaged by chemicals.

It should last a long time and come from a trusted maker.

To keep your ceramics safe, store kiln furniture the right way, check for cracks, and use kiln wash. Doing these things helps your pottery fire evenly and last longer.